Three-claw opening-shrinking machine synchronized through connecting rods

A connecting rod mechanism and connecting rod technology, which is applied in the field of three-jaw necking machine, can solve the influence of the uniformity of the shape, wall thickness and strength of the necking cup, increase the steps and time of the process, and change the center position of the necking, etc. problems, to achieve the effect of facilitating metal flow, shortening process time, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

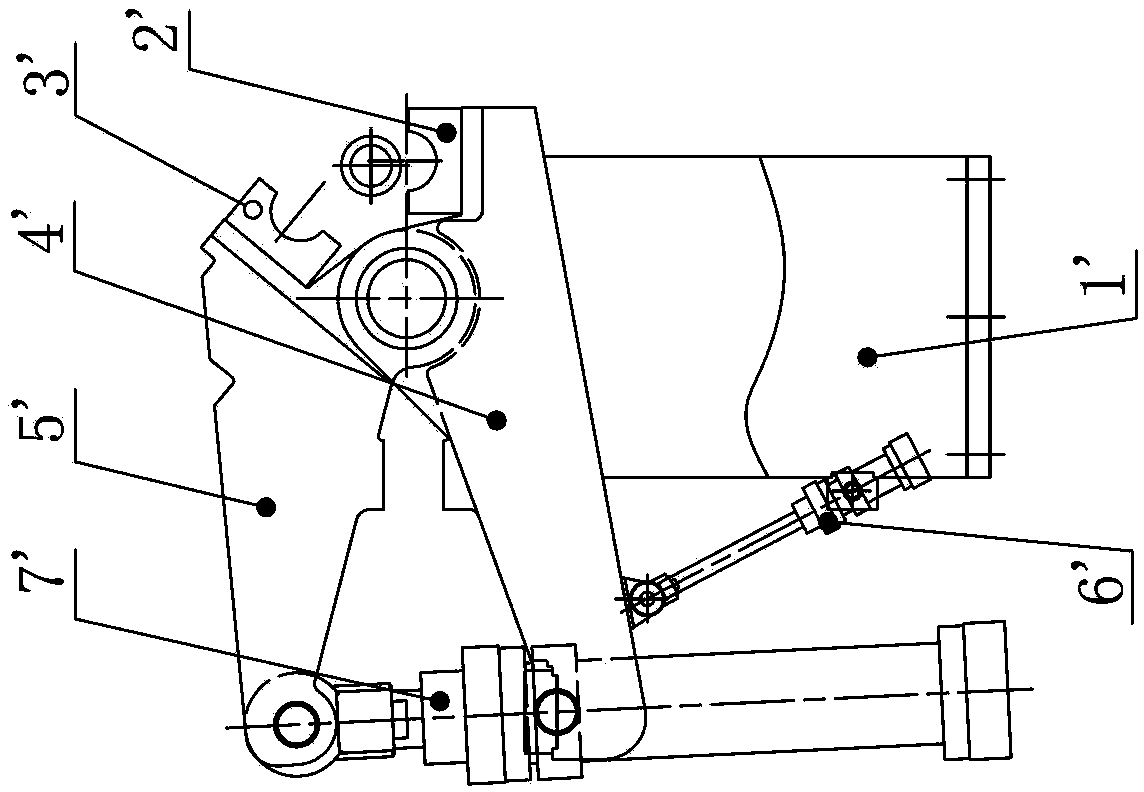

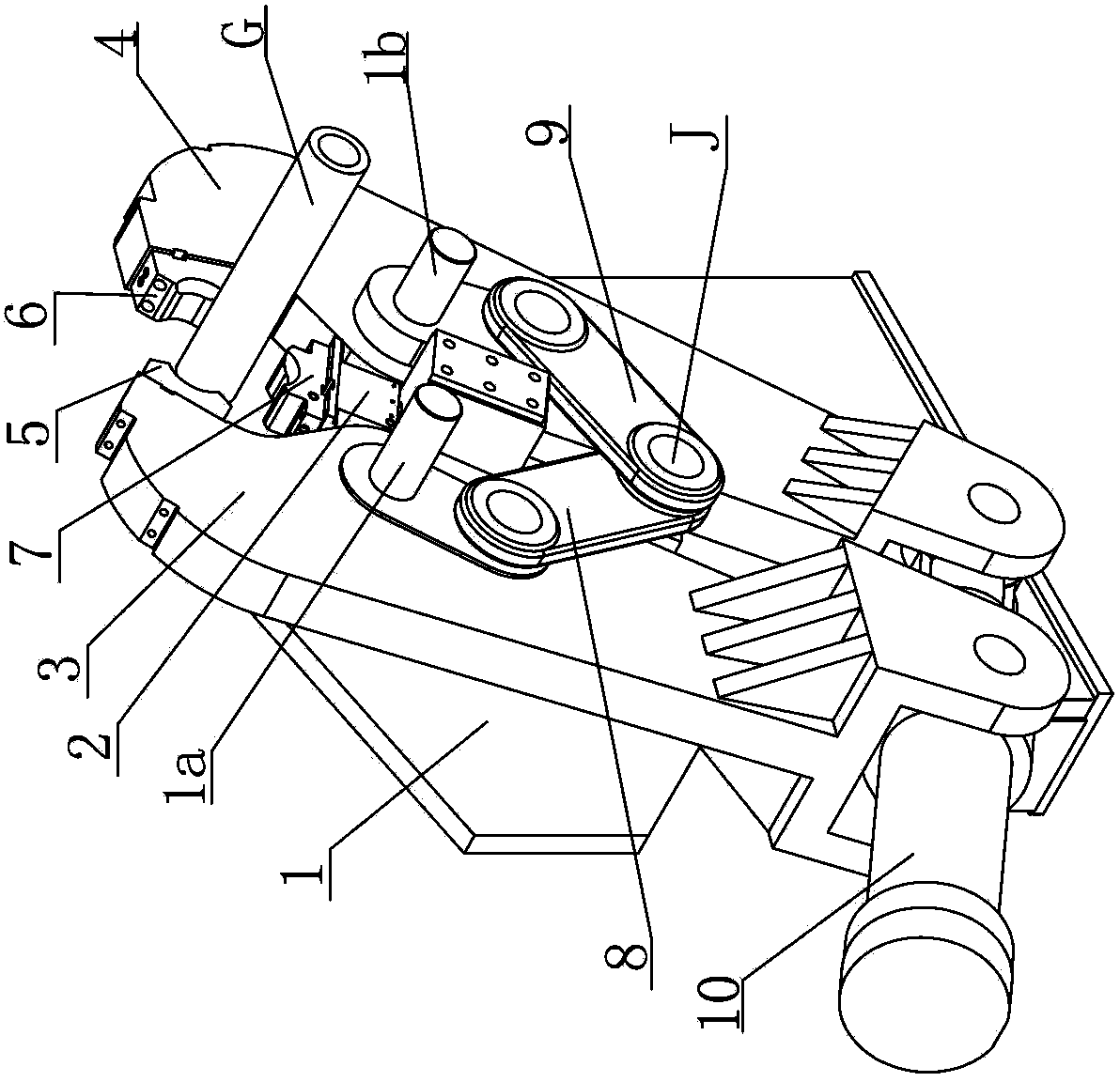

[0042] Figure 3 to Figure 6 The structure of the first embodiment of the present invention is shown. The support in the figure is only partially shown, that is, only the rear side plate and the guide sleeve are shown. As shown in the figure, a kind of through A three-jaw necking machine with synchronous connecting rods, which includes a support 1, a telescopic arm 2, a first rotating arm 3, a second rotating arm 4, the first, second, and third jaws 5, 6, 7, and the first connecting rod Mechanism 8, second link mechanism 9 and executive cylinder 10. The telescopic arm 2 is connected to the support 1 so that it can move up and down. The first rotating arm 3 is rotatably connected to the support 1 through the first pin shaft 1a, and the second rotating arm 4 is rotatably connected to the support 1 through the second pin shaft 1b. , The two rotating arms 3 and 4 are located on both sides of the telescopic arm 2 symmetrically. The first, second and third jaws 5, 6 and 7 are res...

Embodiment approach 2

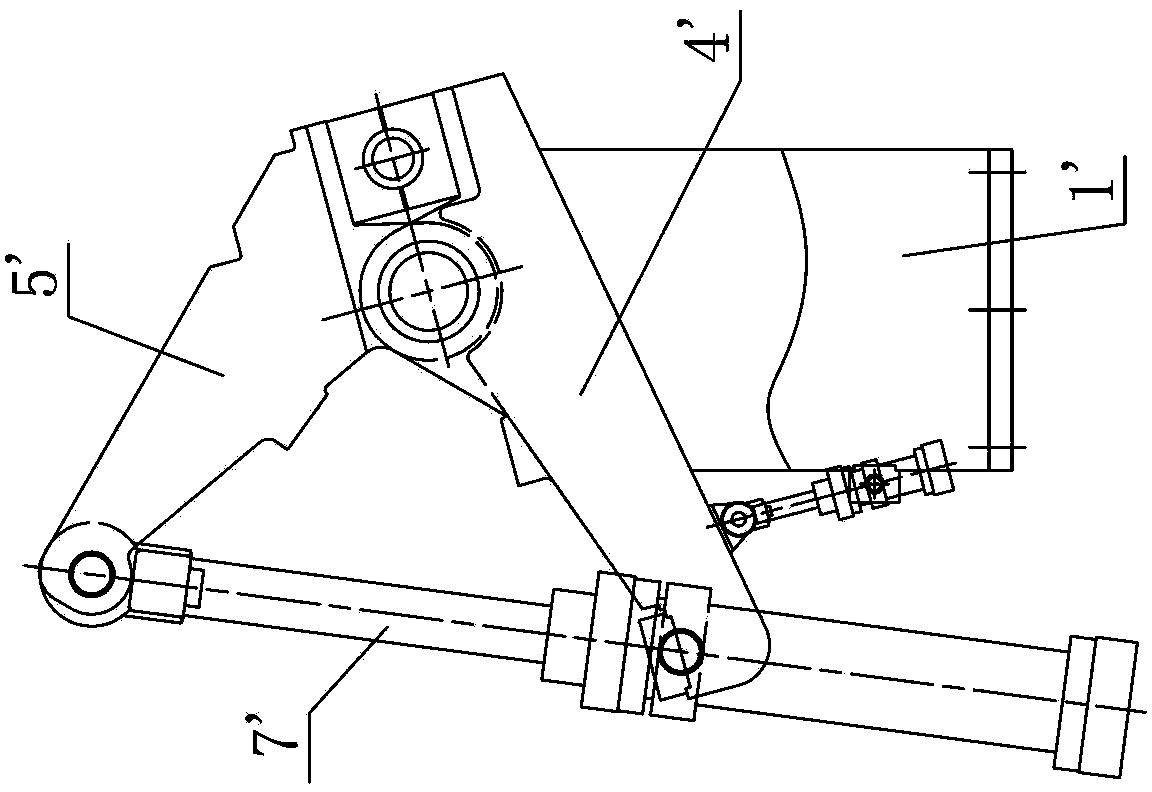

[0059] In the above embodiment, the actuator cylinder 10 is placed along the direction parallel to the line connecting the first and second pin shafts 1a and 1b, which directly drives the first and second rotating arms 3 and 4 to rotate, and then through the first and second linkage mechanisms 8 , 9 drives the telescopic arm 2 to move. In this embodiment, the actuator cylinder 10 is placed vertically, which directly drives the telescopic arm 2 to move, and then through the first and second link mechanisms 8,9, the first and second rotating arms 3,4 are rotated. specifically is,

[0060] Such as Figure 9 , 10 with Figure 10A As shown, the actuator cylinder 10 has a cylinder rod flat head 10a and a cylinder tube trunnion 10b, the cylinder rod flat head 10a is telescopically connected in the cylinder tube trunnion 10b, and the actuator cylinder 10 is placed vertically, One of the cylinder rod flat head 10a and the cylinder trunnion 10b is connected to the bottom of the telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com