Curved Eyelash Brush Head

An eyelash brush and curved technology, applied in the field of cosmetic appliances, can solve the problems of consuming development costs and production costs, consuming preparation time, and discounting the quality of cosmetics, saving development costs and production costs, being easy to replace, and being convenient for development and production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

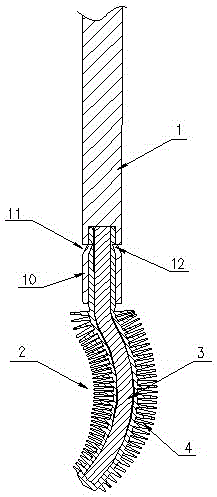

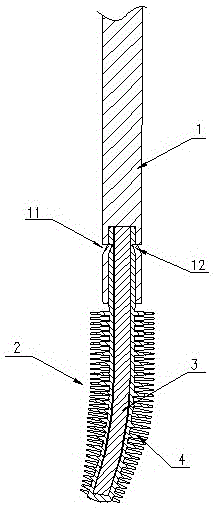

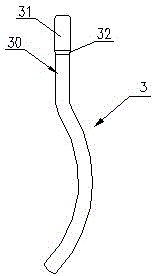

[0018] Embodiment: a curved eyelash brush head, including a bristle rod 1 and a brush head 2, the brush head 2 is detachably connected to one end of the bristle rod 1, and the brush head 2 is sleeved on the curved core rod 3 and tightly pressed. The bristle cover 4 on the curved core rod is composed of a soft tubular hollow cover, and the bristles are radially injected on the surface of the hollow cover. One end of the hollow cover is extended with a socket 40. The curved core rod The main diameter of 3 is integrally bent and formed, and one end of the main diameter is extended with an insertion part 30. When the bristle cover 4 is sleeved on the curved mandrel 3, its hollow sleeve is correspondingly close to the outer wall of the main diameter, and its sleeve part 40 is correspondingly tight. Attach the outer wall of the insertion portion 30; one end of the bristle rod 1 forms an attachment portion 10 connected to the brush head 2, and the end of the attachment portion is conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com