Assembly for actuating an actuator in a motor vehicle

A technology for actuators and motor vehicles, which is applied to vehicle accessories for anti-theft, vehicle components, excitation or armature current control, etc., and can solve the problem of inability to obtain reliable information on the position of the reaching end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

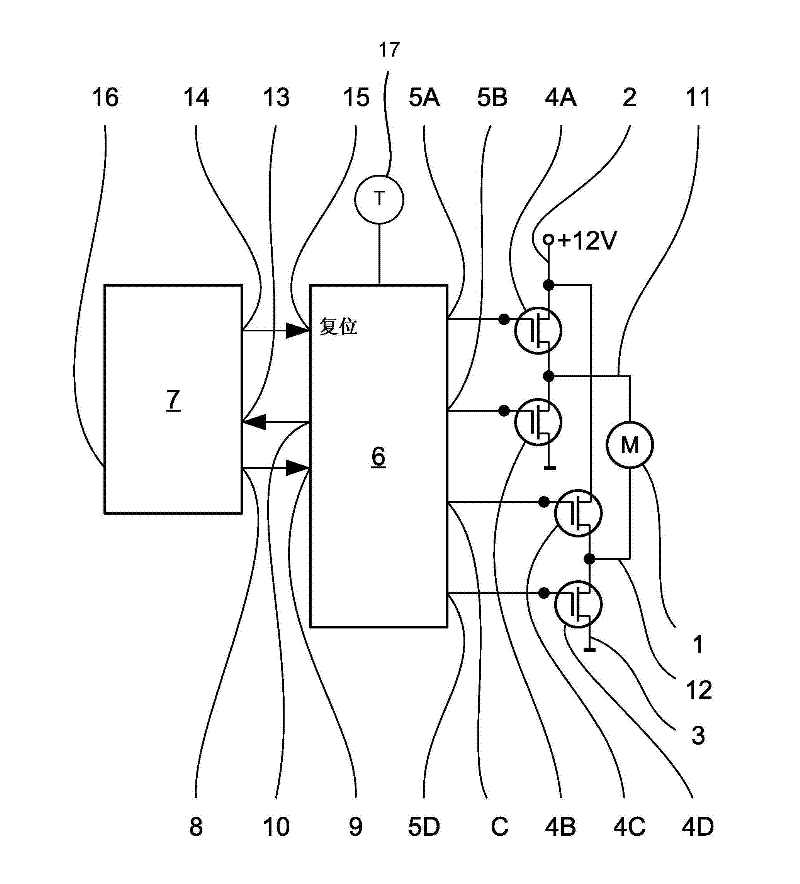

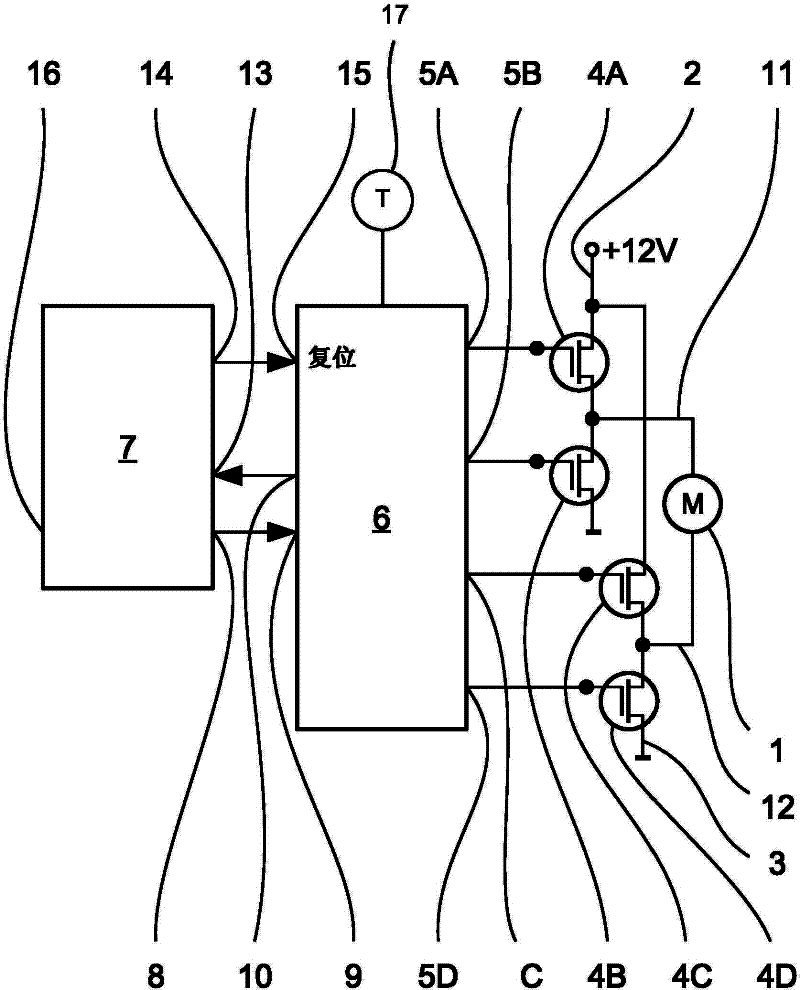

[0028] figure 1 Components of an electronic steering lock (ELV), in particular a motor-driven actuation circuit for the ELV, are shown schematically. A motor 1 , which engages in the steering column by driving the transmission to move the stop pin, is coupled between the supply voltage 2 and ground 3 via power switching means. exist figure 1 In the exemplary embodiment shown schematically, both connections of the motor 1 can be connected either to the supply voltage 2 or to the ground 3, so that the motor can be moved in two directions. An electronic steering lock construction is also known in which the motor always moves in one direction only. In this construct it is possible to cancel figure 1 parts of the power switching device shown in . When the motor 1 should not move, the two terminals of the motor are connected to the ground 3 for safety, that is to say, the power switching device connecting the motor terminals to the ground 3 is caused to remain switched on.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com