Cursor displayed float-type liquidometer

A liquid level gauge and float type technology, applied in the field of liquid level measurement, can solve the problems of increasing manufacturing difficulty and manufacturing cost, limiting the use temperature of the liquid level gauge, affecting the accuracy and sensitivity, etc., so as to reduce reliability, avoid garbled characters and structure. Complex, safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

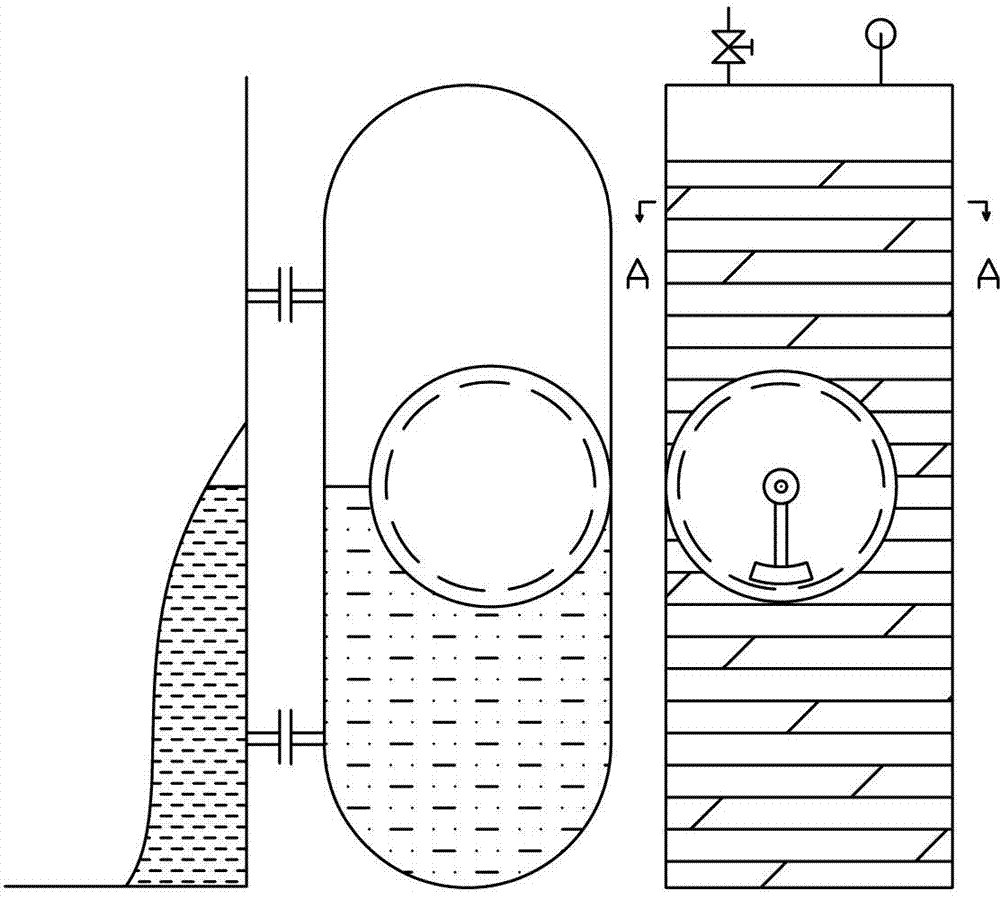

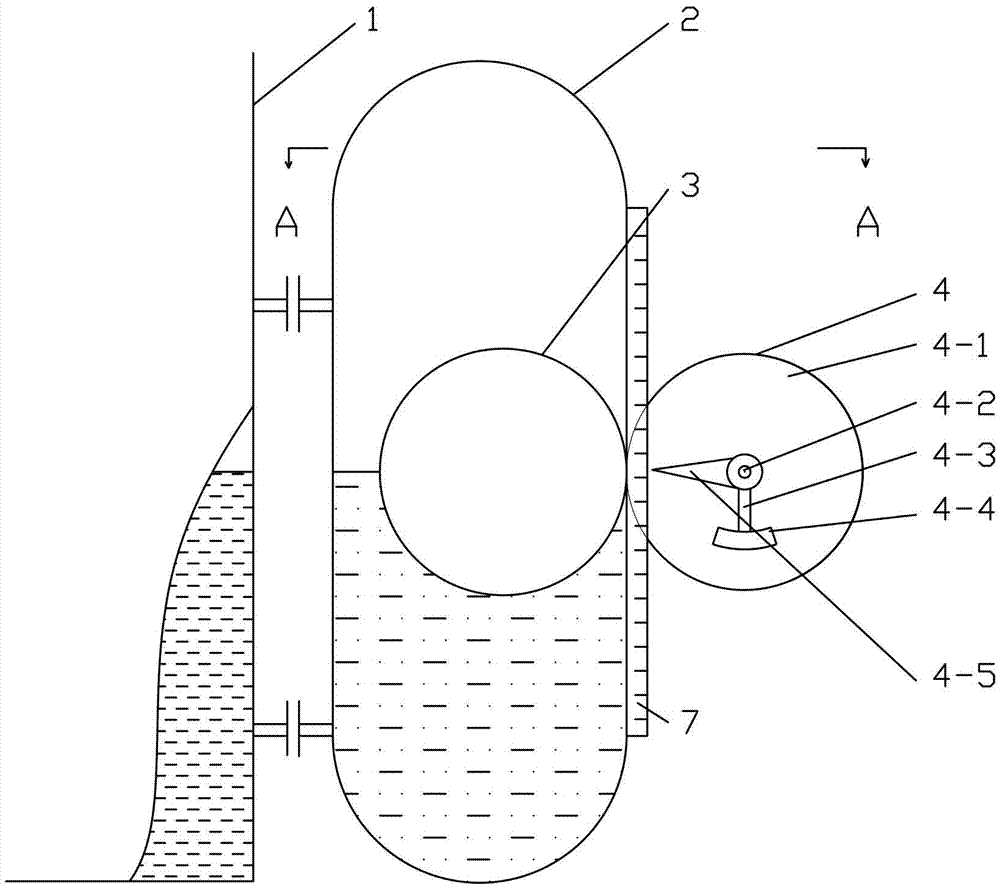

[0059] A float type level gauge with cursor display, such as image 3 , 4 As shown, it includes a non-ferromagnetic material float chamber 2 and its float 3, a vernier system 4, and a scale 7; the float 3 is a hollow sphere made of ferromagnetic material, and the vernier 4 includes a central axis Cylindrical magnet 4-1 with holes, short axis 4-2, connecting rod 4-3, the central hole of the magnet is located on the axis of the magnet and is horizontal, the magnetic poles of the magnet are distributed along the axis or Located on the radial inner and outer surfaces; the short shaft 4-2 passes through the central hole of the magnetic steel and is fixedly installed. The two ends of the short shaft extend out of the magnetic steel 4-1. For the Lianxuan 4-3 that rotates around the axis, the lower ends of the two Lianxuan 4-3 are fixedly connected with the counterweight 4-4 to ensure that the center of gravity of the cursor is on the central axis and below the horizontal centerline of ...

Embodiment 2

[0064] In order to prevent the use of rain, snow, ice, dust, etc. from affecting the use, a vernier chamber 6 made of transparent material can be set on the basis of embodiment 1, and the vernier 4 is installed in it, and the vernier chamber 6 is adjacent to the float chamber 2. Settings like Figure 5 with Image 6 Shown.

[0065] The two magnetic coupling parts are always looking for the shortest distance to be coupled together. Therefore, the float 3 and the cursor 4 always move up and down synchronously at the closest distance. That is: the two will not deviate under normal circumstances. That is, the vernier will not deviate from the plane 5 outside the float chamber 2 which is parallel to the axis of the float chamber 2.

Embodiment 3

[0067] A float type level gauge, such as Figure 7 As shown, the difference from Embodiment 1 is that a pulley 8 is set on the upper frame outside the float chamber 2, one end of the connecting rope or connecting belt 9 is connected to the vernier 4 through the fixing frame 4-6, and the other end is connected to the counterweight 10 Connected; The fixed frame 4-6 is clamped on both sides of the magnet 4-1, and is hinged with the short shaft 4-2.

[0068] When the float 3 is immersed in half of the liquid to be measured, the weight of the counterweight 10 minus the weight of the vernier 4 is equal to the weight of the float 3 minus the buoyancy of the float 3 when it is immersed in half of the liquid to be measured. As a result, the counterweight 10 drives the vernier 4 to give the float 3 an upward lifting force and achieve a force balance.

[0069] When the liquid level rises and falls, the balance of this force is broken, and the cursor 4 and the counterweight 10 move up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com