Double-clutch transmission with synchronizer parking device and without reversing shaft

A dual clutch and synchronizer technology, which is applied to components with teeth, transmission devices, gear transmission devices, etc., can solve the problems of high development cost, high development cost, and basic utilization limit, and achieves simplified overall structure and overall Simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

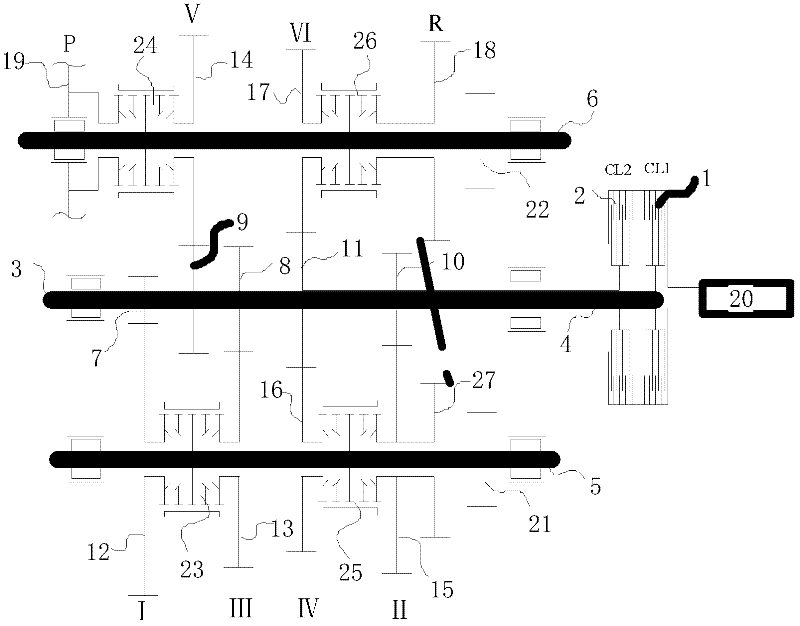

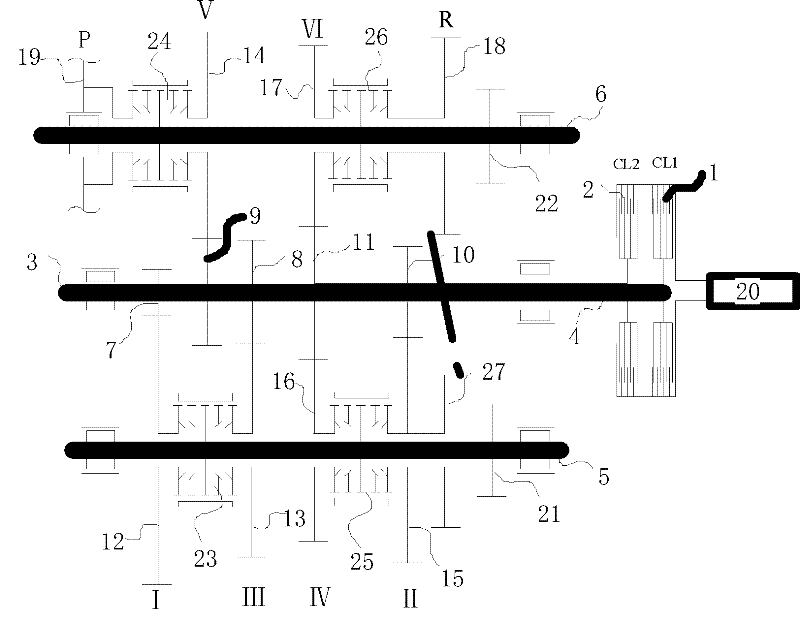

[0013] Embodiments of the present invention (sixth gear) are discussed in detail with reference to the accompanying drawings.

[0014] Such as figure 1 As shown, a dual-clutch transmission with a synchronizer parking device and no reverse gear shaft adopts a dual-clutch device integrated with the first clutch 1 and the second clutch 2, and the input shaft consists of the inner shaft 3 and its outer sleeve shaft 4 The combined double transmission input shaft, the first clutch 1 is connected with the inner shaft 3, and the first-speed driving gear 7, the third-speed driving gear 8, and the fifth-speed driving gear 9 are arranged on it; the second clutch 2 is connected with the sleeve shaft 4, The second gear driving gear 10, the fourth gear and the sixth gear share the driving gear 11 on it.

[0015] The present invention adopts two output shafts, the first gear driven gear 12 and the third gear driven gear 13 arranged on the output shaft one share a synchronizer one 23, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com