Two-stroke opposed-piston diesel engine

A diesel engine and opposed piston technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of low energy conversion efficiency, long manufacturing cycle, and high maintenance cost, and achieve high energy conversion efficiency and low manufacturing replacement costs Low, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

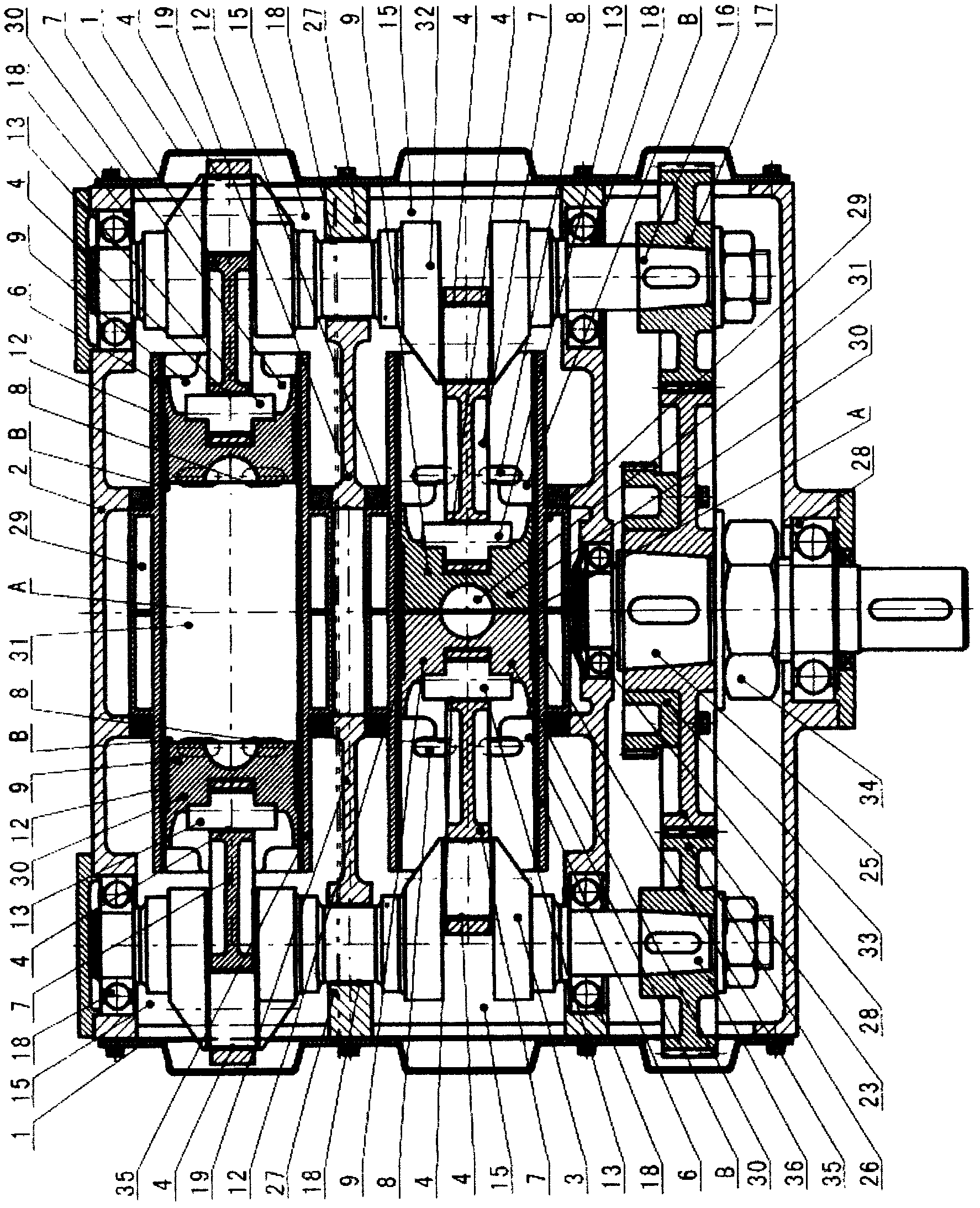

[0026] Further details are given below in accordance with the accompanying drawings:

[0027] Such as figure 1 , image 3As shown, the cylinder block 2 is the installation base and supporting framework of the two-stroke opposed-piston diesel engine. The cooling water jacket 29 is integrated inside the cylinder barrel 6 to cool the cylinder barrel 6, the piston mechanism 30, the fuel nozzle 10, the exhaust valve 22 and the like. The cylinder barrel 6 fixed on the horizontal plane can be divided into two parts with the same structure on the left and right from the center. The notch 5 is arranged at the two ends of the cylinder barrel 6 corresponding to the big end of the connecting rod 7. The function of the notch 5 is to avoid when the connecting rod 7 moves. The movement space of the connecting rod 7 large ends reduces the width of the engine and the length and quality of the moving parts, and reduces the self-load of the engine. Air inlets 8 of varying numbers are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com