Sealing device for long-range transport ship-loading system

A sealing device and long-distance technology, applied in the field of mechanical equipment, can solve the problems of flying dust and low shipping efficiency, and achieve the effects of convenient sealing operation, weight reduction, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

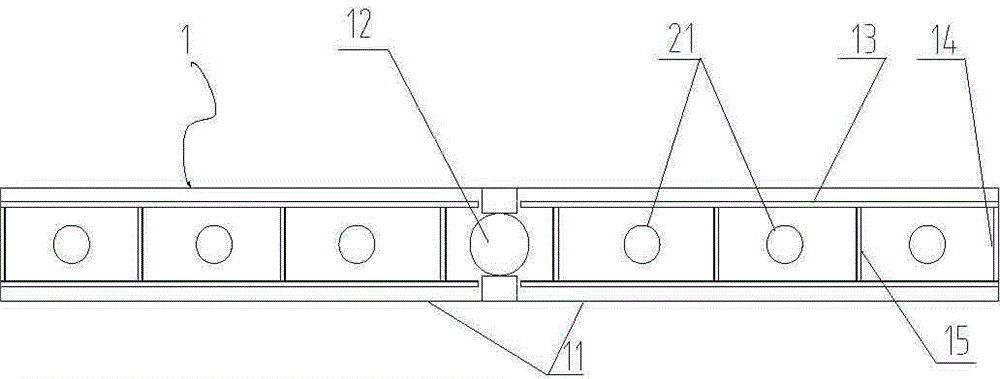

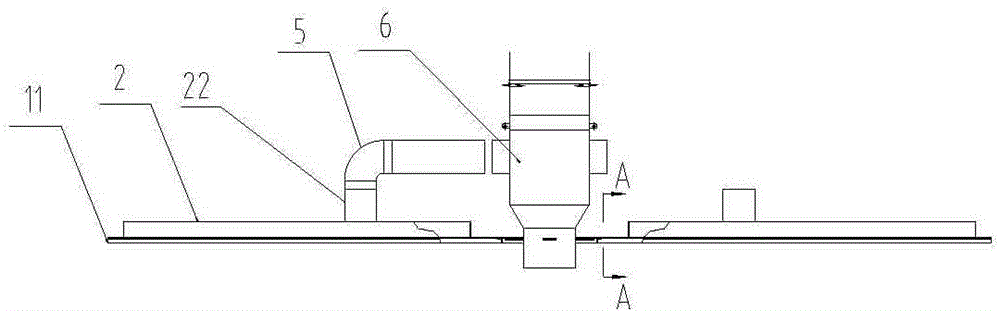

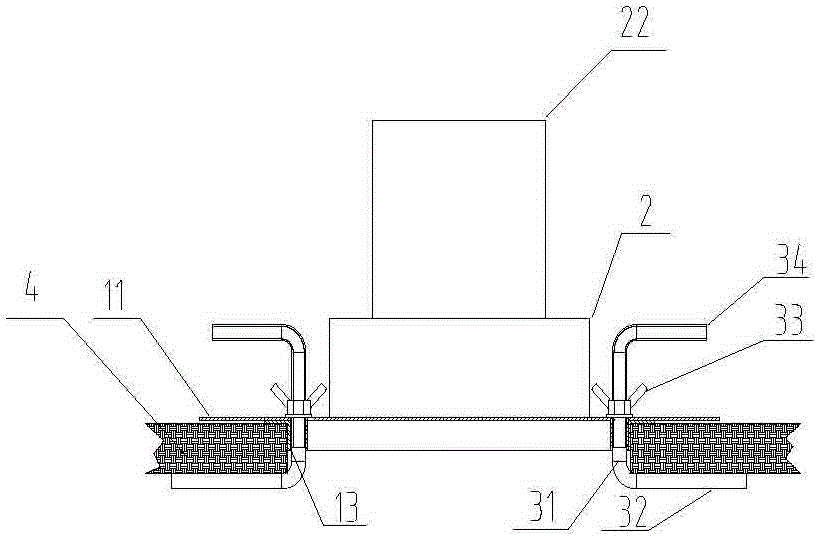

[0029] Such as Figure 1-Figure 3As shown, a sealing device that can be used for long-distance transportation and loading system includes a fixed plate 1 that is used to seal the opening of the cabin and can be fixedly connected with the side plates 4 on both sides of the opening of the cabin; the fixed plate 1 is A rectangular steel plate is formed by combining two splicing blocks 11 with semicircular notches at the ends. The feeding port 12 is a circular opening matching the shape of the end of the charging pipe 6, and is connected by the circular notches of the two splicing blocks 11. made.

[0030] The bottom surface of each of the splicing blocks 11 is provided with a supporting frame for supporting the splicing block 11, specifically, the supporting frame consists of long side angle irons 13 along the long side direction of the fixed plate 1 and fixed along the The short-side angle irons 14 in the short-side direction of the plate 1 are combined, and the long-side angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com