Staggered-pliers-type hazel shell cracking machine

A hazelnut shelling machine and hazelnut technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of high difficulty in shelling, low efficiency of shelling, and inappropriate knocking position, etc., to achieve the guaranteed effect of shelling, Avoid repeated shell breaking and avoid feeding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

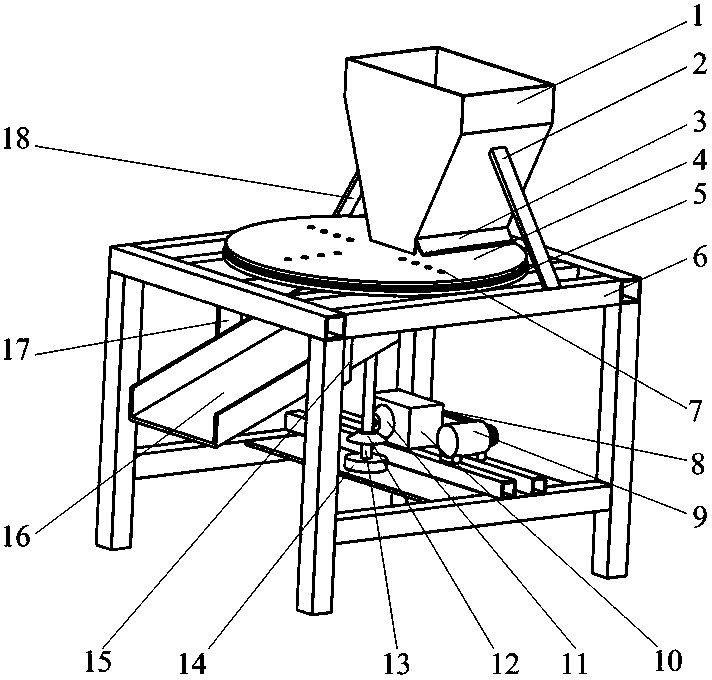

[0020] refer to figure 1 , The frame 6 of the present embodiment is equipped with a hazelnut feeding device, a hazelnut breaking device, a hazelnut discharge device and a power transmission device.

[0021] refer to figure 1 , The hazelnut feeding device of the present embodiment includes a feeding hopper 1 and a cleaning brush 3, the feeding hopper 1 is fixed on the frame 6 table through the support plate I 2 and the support plate II 18, and the cleaning brush 3 is connected to the bottom of the feeding hopper 1.

[0022] refer to Figure 1 ~ Figure 4 , the hazelnut cracking device of the present embodiment includes a reclaiming turntable 4, a fixed extruding block 23, a sliding extruding arm 25, a return spring 26, a cam 19 and a fixed disc 5; and the bottom of cleaning brush 3, the lower part of the reclaiming carousel 4 is close to the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com