Preparation method of textured wheat protein

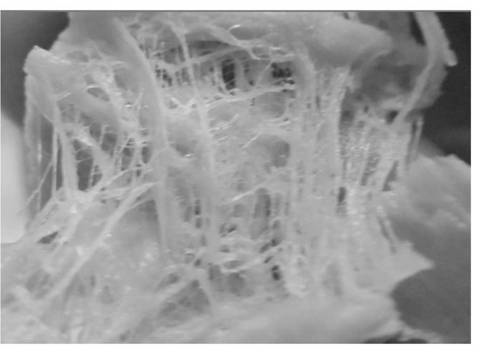

A protein and wheat technology, applied in the field of wheat textured protein preparation, can solve the problems of inappropriate extrusion process parameters, easy clumping and clogging of wheat protein, etc., and achieve the effects of enriching fiber filaments, strengthening interaction, and obvious layered structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Mix 300kg of gluten powder, 3kg of L-cysteine, 2.1kg of calcium chloride, and 1.5kg of monoglyceride and pour them into the feed scale. Dissolve 0.5kg of sodium hydroxide and 0.4kg of glycerin in 10kg of water to prepare Conditioner solution, cooled to room temperature for later use; turn on modulator, feed water pump, micro flow pump, extruder, feed water pump flow rate 21kg / h, water temperature 18°C, micro flow pump flow rate 7.5kg / h; extruder preheat When the temperature reaches 100~120°C, start feeding, start feeding speed 100kg / h, screw speed 300rpm; when the temperature in the fifth zone of the extruder reaches 180°C, increase the feeding speed to 180kg / h, increase the screw speed to 450rpm; After the pressure and torque of the press are stabilized, the wheat textured protein product is obtained; the product is cut and sent into the fluidized bed through the air delivery system for drying at a drying temperature of 60°C. Under this process condition, the material ...

Embodiment 2

[0034] Stir 255kg of gluten powder and 45kg of wheat starch in a blender and pour them into the feeding scale; dissolve 1.5kg of sodium hydroxide in 10kg of water to prepare a conditioner solution, cool to room temperature for later use; turn on the modulator and water feeding pump , Trace flow pump, extruder, feed water pump flow rate 21kg / h, water temperature 30°C, trace flow pump flow rate 10kg / h; extruder starts feeding when preheated to 100~120°C, start feeding speed 100kg / h , the screw speed is 300rpm; when the temperature in the fifth zone of the extruder reaches 170°C, the feeding speed is increased to 150kg / h, and the screw speed is increased to 350rpm; after the pressure and torque of the extruder are stable, the wheat textured protein product is obtained; The product is cut and then enters the fluidized bed through the air delivery system for drying at a drying temperature of 50°C. Under this process condition, the material seldom blocks the feeding pipe and modulat...

Embodiment 3

[0036] 255kg of gluten powder, 45kg of potato starch, 4.5kg of L-cysteine, 1.4kg of calcium chloride, and 1.0kg of monoglyceride were mixed in the mixer and poured into the feed scale; 1.0kg of sodium hydroxide, Dissolve 0.3kg of glycerin in 10kg of water to make a conditioning agent solution, cool to room temperature for later use; turn on the modulator, water feeding pump, micro flow pump, and extruder, the flow rate of the water feeding pump is 13kg / h, the water temperature is 25°C, and the flow rate of the micro flow pump is 10kg / h; start feeding when the extruder is preheated to 100~120°C, the starting feeding speed is 100kg / h, and the screw speed is 300rpm; when the temperature in the fifth zone of the extruder reaches 175°C, increase the feeding speed to 170kg / h , the screw speed is increased to 400rpm; after the pressure and torque of the extruder are stable, the wheat textured protein product is obtained; the product is cut and sent into the fluidized bed through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com