Telescopic follow-up control method and system of suspension arm

A boom, telescopic oil cylinder technology, applied in the direction of speed/acceleration control without auxiliary power, transportation and packaging, load hanging components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

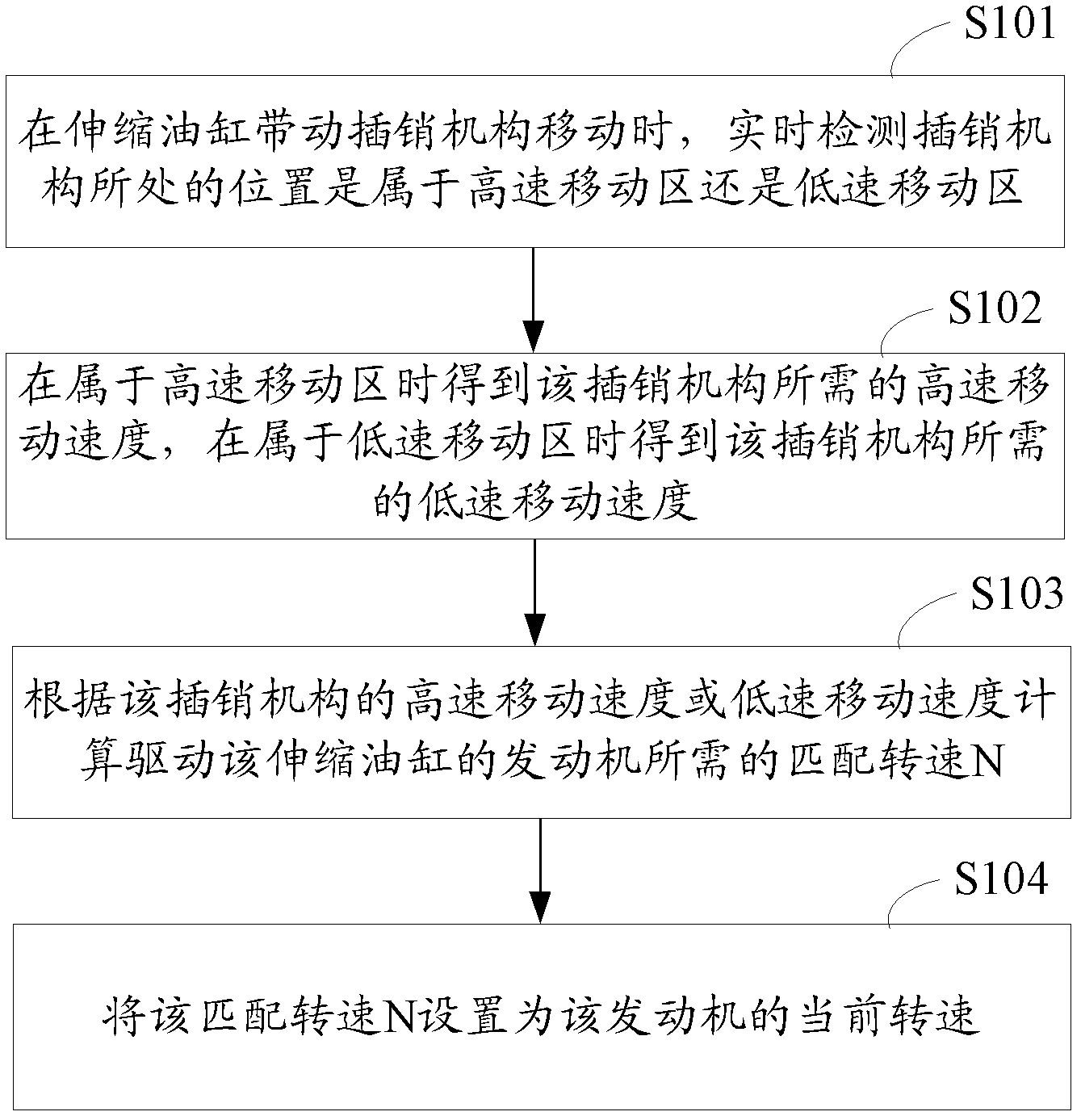

[0053] see figure 1 , is a schematic flowchart of an embodiment of the boom telescoping follow-up control method of the present invention. In this embodiment, the boom telescopic follow-up control method includes:

[0054] Step S101, when the telescopic oil cylinder drives the bolt mechanism to move, detect in real time whether the position of the bolt mechanism belongs to the high-speed moving area or the low-speed moving area.

[0055] Before this step S101, the user first inputs the purpose state that the boom needs to be extended, and then activates the automatic telescopic switch, and the telescopic oil cylinder drives the bolt mechanism to insert the bearing pin on the multi-section arm. When the multi-section arm needs to be extended , the telescopic oil cylinder drives the latch mechanism to find the tail of the j-th telescopic arm to be extended, and stretches out the working pin to lock the telescopic oil cylinder and the j-th telescopic arm to ensure that the j-th ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com