Method and device for solving contamination of boiler convection heating surface

A heating surface and boiler technology, which is applied in the field of solving the contamination of the convection heating surface of the boiler, can solve the problems that cannot be effectively solved, the convection heating surface of the boiler is easy to be contaminated, and cannot be removed, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

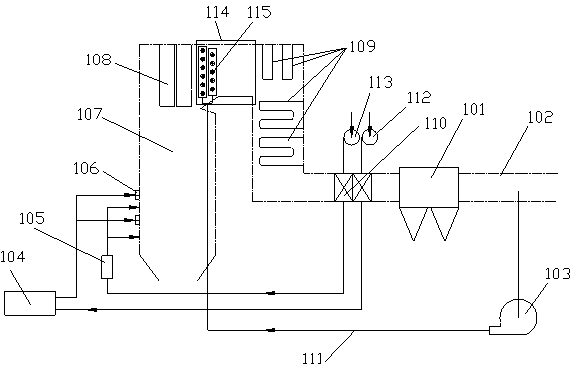

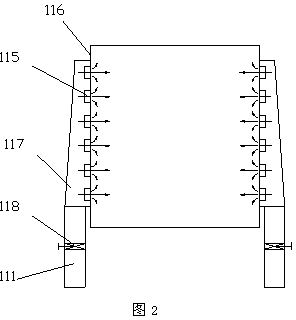

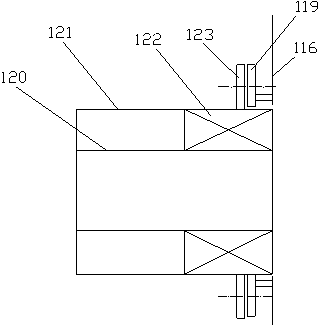

[0039] The boiler is a Π-type furnace, and the Π-type furnace includes a furnace, a flue, a dust collector, an air preheater, a primary flue gas recovery fan, a secondary flue gas recovery fan, a pulverizing device and a burner. The heating surface is set in the furnace and the tail flue, the flue gas mixing chamber is set between the furnace outlet and the tail heating surface, the air preheater is set in the flue behind the tail flue, and the primary flue gas returns to the exhaust fan and the secondary flue gas. The air return exhaust fans are respectively connected with the air preheater, and the air is sent into the air preheater to be heated to form corresponding hot primary air and hot secondary air. After entering the pulverizing device, the hot primary air enters the furnace through the burner, and heat The secondary air enters the furnace through the bellows. The flue gas mixing chamber is provided with a flue gas nozzle, and the air outlet of the flue gas return fan...

Embodiment 2

[0045] The boiler is a tower furnace, and the tower furnace includes a furnace, a flue, a dust collector, an air preheater, a primary flue gas return fan, a secondary flue gas return fan, a pulverizing device and a burner. The heating surface is divided into an upper heating surface whose flue gas temperature is lower than T1 and a lower heating surface whose flue gas temperature is higher than T2. The flue gas mixing chamber is set between the upper heating surface and the lower heating surface, and the air preheater is set In the flue behind the flue, the primary flue gas return fan and the secondary flue gas return fan are respectively connected to the air preheater, and the air is sent into the air preheater to be heated to form corresponding hot primary air and hot secondary air. After the primary air enters the pulverizing device, it enters the furnace through the burner, and the hot secondary air enters the furnace through the bellows. The flue gas mixing chamber is p...

Embodiment 3

[0050] The boiler is a CFB boiler, and the CFB boiler includes a furnace, an air distribution device, a flue, a dust collector, a separator, an air preheater, a primary flue gas recovery fan, a secondary flue gas recovery fan, the outlet of the furnace and the separation The flue gas mixing chamber is set between the separator and the rear heating surface, the air preheater is set in the flue behind the tail flue, and the primary flue gas return fan and the secondary flue gas return fan are connected with the air preheater respectively. The heaters are connected, and the air is sent into the air preheater to be heated to form corresponding hot primary air and hot secondary air. The hot primary air enters the furnace through the air distribution device, and the hot secondary air enters the furnace through the bellows. The flue gas mixing chamber is provided with a flue gas nozzle, and the air outlet of the flue gas return fan is connected with the flue gas nozzle.

[0051] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com