Flat-type air vibration isolator

An air vibration isolator, flat technology, applied in the direction of gas shock absorber, etc., can solve the problems of poor system stability and high center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

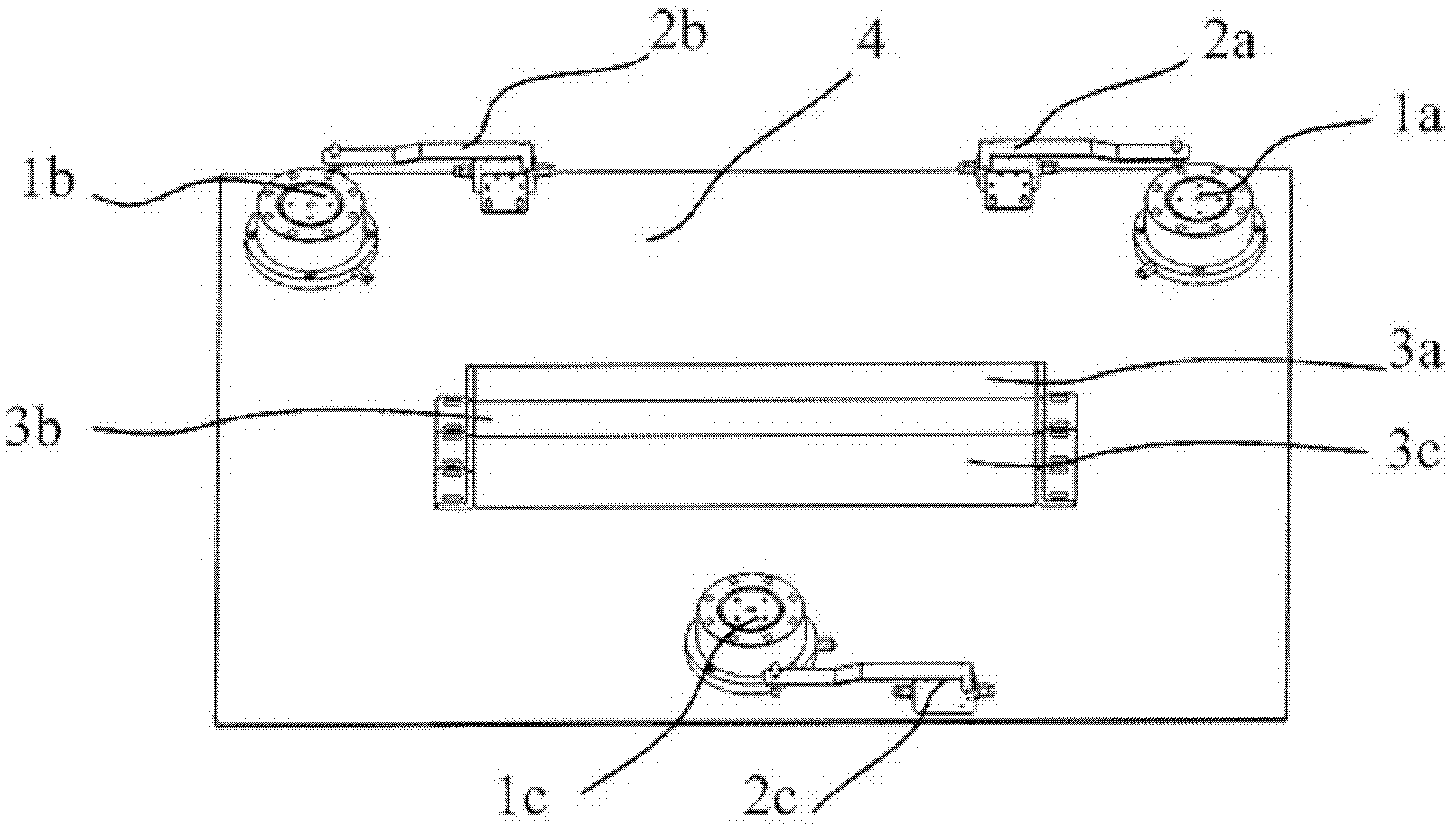

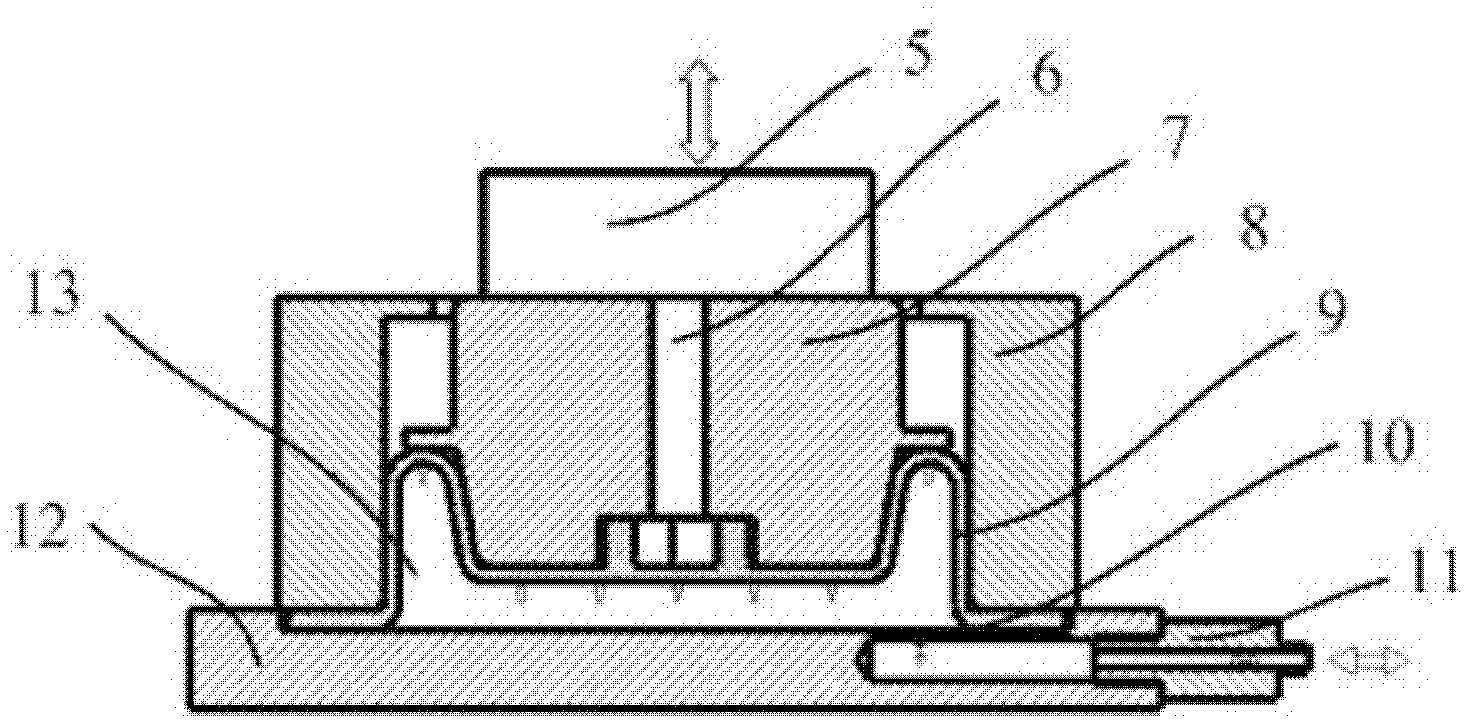

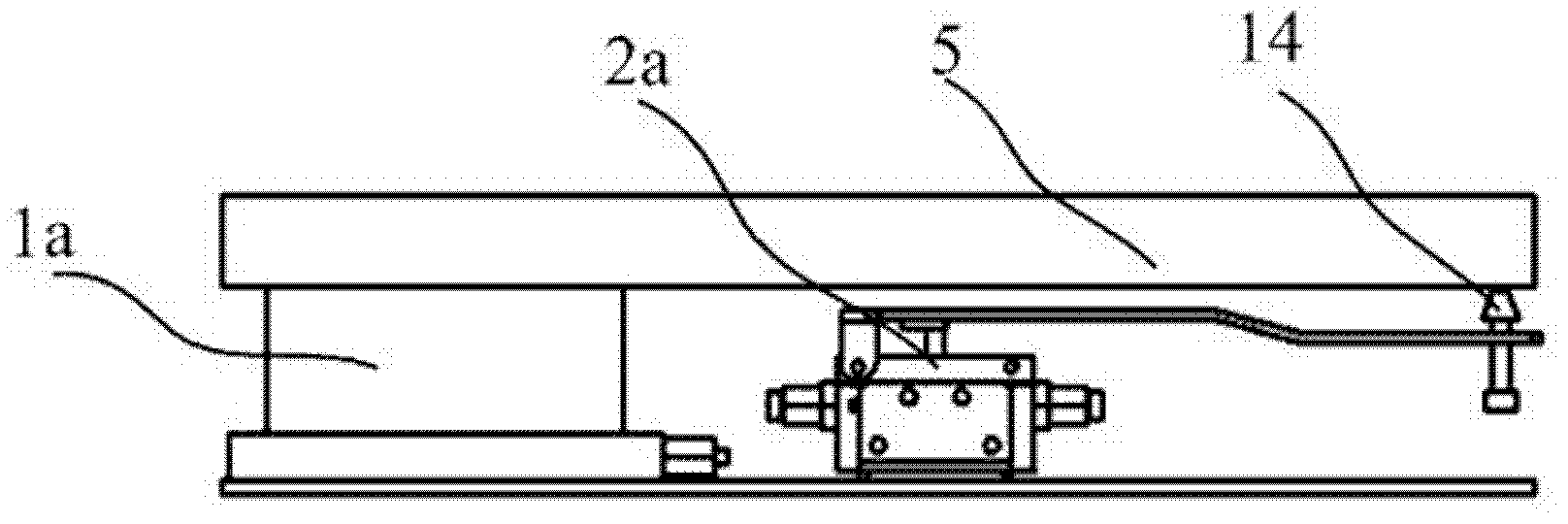

[0020] Another embodiment provided by the present invention is: the air vibration isolator includes a casing 4 and four main chambers and four additional air chambers arranged in the casing, the four main chambers are arranged in a quadrangular shape, and the four Three additional air chambers are arranged side by side in the space formed by the four main chambers; each main chamber includes a piston 7, a pressure ring 8, a rubber sealing ring 9 and a bottom plate 12; the rubber sealing ring 9 is fixed by a fixing bolt On the piston 7, a closed concave cavity 13 is formed between the rubber seal ring, the pressure ring 8 and the bottom plate 12; the bottom plate 12 is provided with a damping hole 10 and an air pipe joint 11, and the concave cavity of the four main chambers The chambers communicate with the four additional air chambers through their respective damping holes and tracheal joints.

[0021] figure 2 It is a schematic diagram of the structure principle of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com