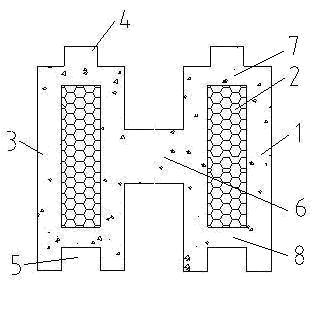

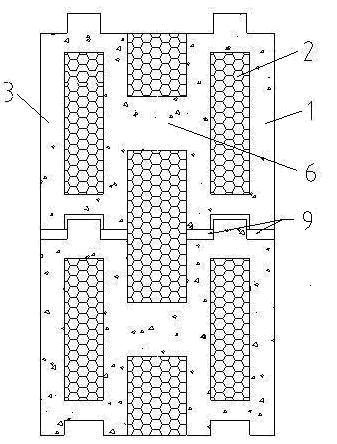

H-shaped cross bore chain-type concrete block

A technology of concrete blocks and horizontal holes is applied in the field of building materials, which can solve the problems of low bearing capacity and inability to use load-bearing walls, and achieve the effects of low cost, meeting fire protection requirements and high service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0030] The difference between this embodiment and the first embodiment is that the upper and lower concrete blocks are bonded by fine stone concrete.

Embodiment 3

[0032] The difference between this embodiment and the first embodiment is that the insulating material filled in the cavity formed by the hollow cuboid 1, the hollow cuboid 2 3 and the upper and lower concrete blocks is polyurethane foam.

Embodiment 4

[0034] The difference between this embodiment and the first embodiment is that the insulating material filled in the cavities formed by hollow cuboid 1, hollow cuboid 2 3 and upper and lower concrete blocks is rock wool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com