Lubricating structure between saddle and base body of bridge and lubricating method

A saddle and seat body technology, applied in bridges, bridge parts, bridge maintenance, etc., can solve the problems of not reaching the saddle and seat body, reducing frictional resistance, deformation and damage of tetrafluoroethylene plate, etc., to achieve easy movement and Labor-saving and load-bearing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

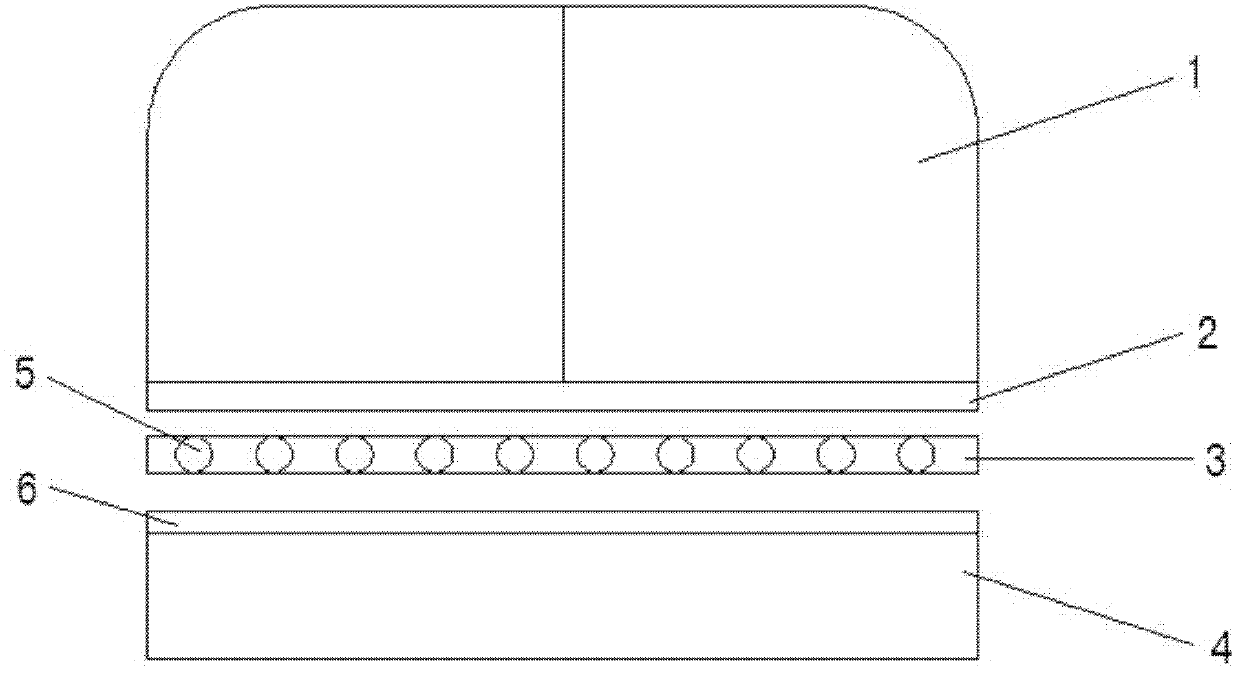

[0021] Examples (see attached figure 1 ):

[0022] 1. Pre-treatment of iron castings and roughening by sandblasting.

[0023] The pre-treatment of iron castings is divided into two parts: degreasing treatment and sandblasting treatment.

[0024] Degreasing treatment, using a normal temperature water-based high-efficiency degreasing agent, thoroughly removes all kinds of grease and micro-garbage during the machining process of iron castings, and washes them with water.

[0025] After water washing, dry the surface of the workpiece with high-pressure oil-free high-pressure gas.

[0026] Sandblasting, using on-site sandblasting machinery, makes the surface of the workpiece obtain the necessary roughness, improves the mechanical properties of the workpiece surface, improves the fatigue resistance of the workpiece, increases the adhesion between it and the coating, and prolongs the coating. The durability of the film is also conducive to the leveling of the coating. Sand blasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap