Yarn trapper for sewing machine

A thread tensioner and sewing machine technology, which is applied to sewing equipment, sewing machine components, sewing machine control devices, etc., can solve problems such as high heat generation, adjustment of clamping force, and impact on the service life of the thread tensioner, so as to prolong the service life, The effect of preventing overheating and accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

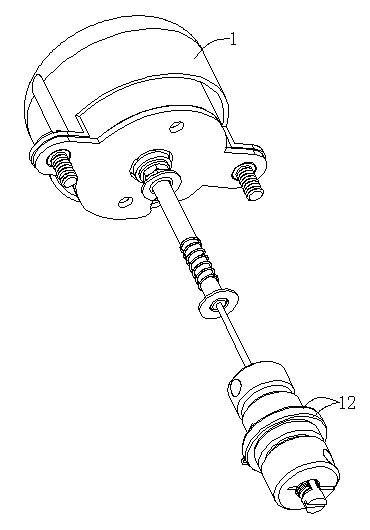

[0022] A thread gripper for a sewing machine usually includes two tension discs 12 for clamping sutures. The two tension discs 12 are arranged on the installation shaft in series, and the two tension discs 12 are driven to each other by the electromagnet 1. Clamping, the suture can maintain proper tension when the sewing machine is working.

[0023] The thread tensioner in this embodiment includes a thread tension disk 12 for thread tension, an electromagnet 1 for driving the thread tension disk 12 to clamp the thread, and a control circuit for driving the electromagnet 1 to act.

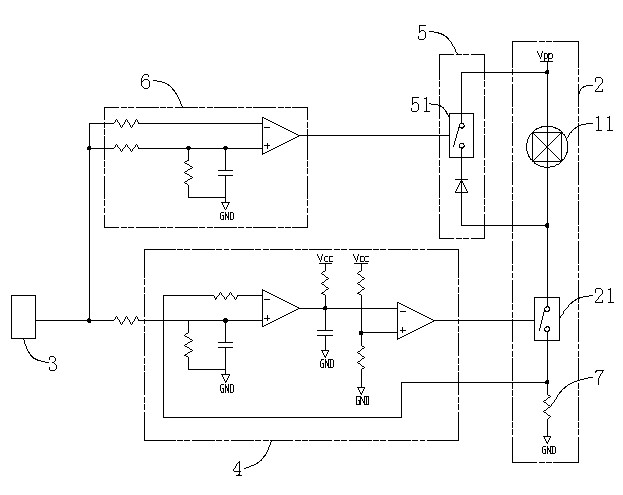

[0024] The control circuit is provided with a drive circuit 2 connected to the coil 11 of the electromagnet 1 . The drive circuit 2 can provide power to the coil 11 to make the electromagnet 1 work to drive the two clamping discs 12 to clamp each other.

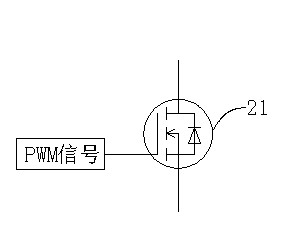

[0025] The driving circuit 2 is connected with a driving switch module 21 for controlling the current of the coil 11 to be turned on or off insta...

Embodiment 2

[0029] This embodiment is a further improvement on the basis of Embodiment 1. In this embodiment, the control circuit includes a driving circuit 2 and a driving switch module 21, and is provided with a signal generating circuit 3 for generating an analog signal and a PWM signal generating circuit 4 for generating an adjustable duty cycle.

[0030] When the wire clamping is required, the signal generating circuit 3 outputs an analog control signal.

[0031] The PWM signal generating circuit 4 receives the analog control signal, and outputs a PWM signal corresponding to the duty cycle according to the level value of the analog control signal.

[0032] The driving switch module 21 receives the PWM signal, and responds to instantaneously turn on the current or turn off the current according to the PWM signal.

[0033] The control circuit of this embodiment realizes controlling the ratio of the instantaneous on-current to the instantaneous off-current in the coil 11 through an ana...

Embodiment 3

[0036] This embodiment is a further improvement on the basis of Embodiment 2. In this embodiment, the control circuit is provided with a release circuit 5 connected to the coil 11 . When the drive circuit 2 cuts off the current of the coil 11, or the current in the coil 11 suddenly decreases, the release circuit 5 is turned on, so that the inductive energy storage of the coil 11 can be released as soon as possible to avoid electromagnetic interference to the circuit.

[0037] A release switch module 51 may also be provided in the release circuit 5 . When the thread tensioner is in normal working state, the release switch module 51 disconnects the release circuit 5 . When the drive circuit 2 cuts off the current of the coil 11 or the current in the coil 11 suddenly decreases, the release switch module 51 turns on the release circuit 5 to release the inductive energy storage of the coil 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com