Method for inferior gasoline modification

A low-quality gasoline and gasoline technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve problems such as large octane loss, achieve small octane loss, reduce olefin content, and avoid dry point indicators The effect of exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

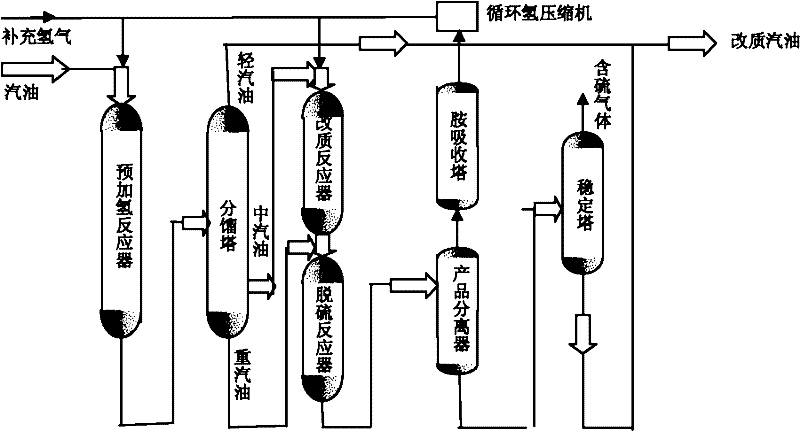

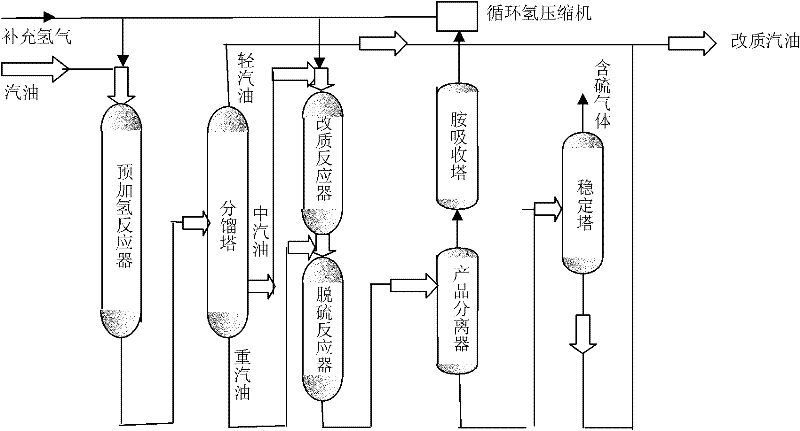

Method used

Image

Examples

Embodiment 1

[0028] The raw material oil that embodiment 1 uses is identical with comparative example. Catalytic gasoline is pretreated under the conditions of hydrogen partial pressure of 2.2Mpa and temperature of 160°C, and then enters the fractionating tower to be cut into three components of light, medium and heavy gasoline. The fraction of medium gasoline accounts for 40% of the raw material, and the fraction of heavy gasoline accounts for 15%. Medium gasoline is firstly mixed with hydrogen into the hydro-upgrading reactor, under the reaction conditions of hydrogen partial pressure of 2.0MPa and reaction temperature of 380°C, the hydro-upgrading is carried out, and then mixed with heavy gasoline into the hydrodesulfurization reactor under the hydrogen partial pressure Supplementary refining is carried out under the conditions of 1.8MPa and 258°C. The supplementary refined product is stabilized by the stabilizing tower and mixed with light gasoline to obtain a clean gasoline product. ...

Embodiment 2

[0030] The raw material oil that embodiment 2 uses is identical with comparative example. Catalytic gasoline is pretreated under the conditions of hydrogen partial pressure of 2.2Mpa and temperature of 160°C, and then enters the fractionating tower to be cut into three components of light, medium and heavy gasoline. Medium gasoline fraction accounts for 50% of the raw material, and heavy gasoline fraction accounts for the raw material. 15%. Medium gasoline is firstly mixed with hydrogen into the hydro-upgrading reactor, under the reaction conditions of hydrogen partial pressure of 2.0MPa and reaction temperature of 380°C, the hydro-upgrading is carried out, and then mixed with heavy gasoline into the hydrodesulfurization reactor under the hydrogen partial pressure Supplementary refining is carried out under the conditions of 1.8MPa and 272°C. The supplementary refined product is stabilized by the stabilizing tower and mixed with light gasoline to obtain a clean gasoline produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com