Carrageenan liquid/jelly, and preparation method and use method thereof

A carrageenan and kylin vegetable technology, which is applied in the directions of food preparation, application, food science, etc., can solve the problems of high energy consumption of carrageenan drying and milling, increase the production cost of meat products, destroy water-retention genes, etc. Great effect, high water retention and gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

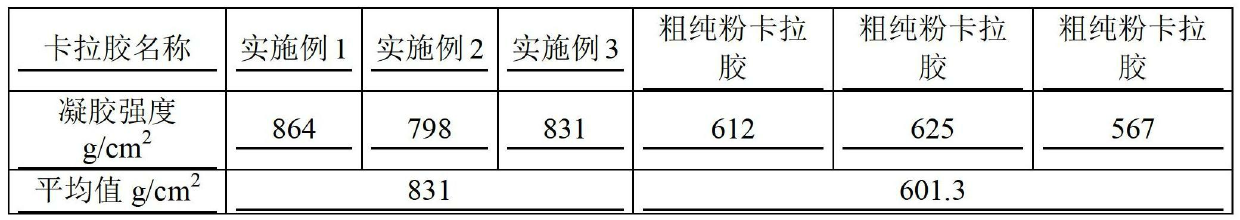

Examples

Embodiment 1

[0017] Take 50kg of dried Eucheuma, rinse it with clean water, put it in a reaction kettle, add 500L of water, and add 50kg of sodium hydroxide at the same time, soak for 1 hour at 70°C; soak and rinse the soaked Eucheuma in the reaction kettle with clean water, Then put it into a glue pot, add 500L of water, and cook at 95°C for 30 minutes; filter while hot after cooking, and use the filtrate directly before it is completely cooled.

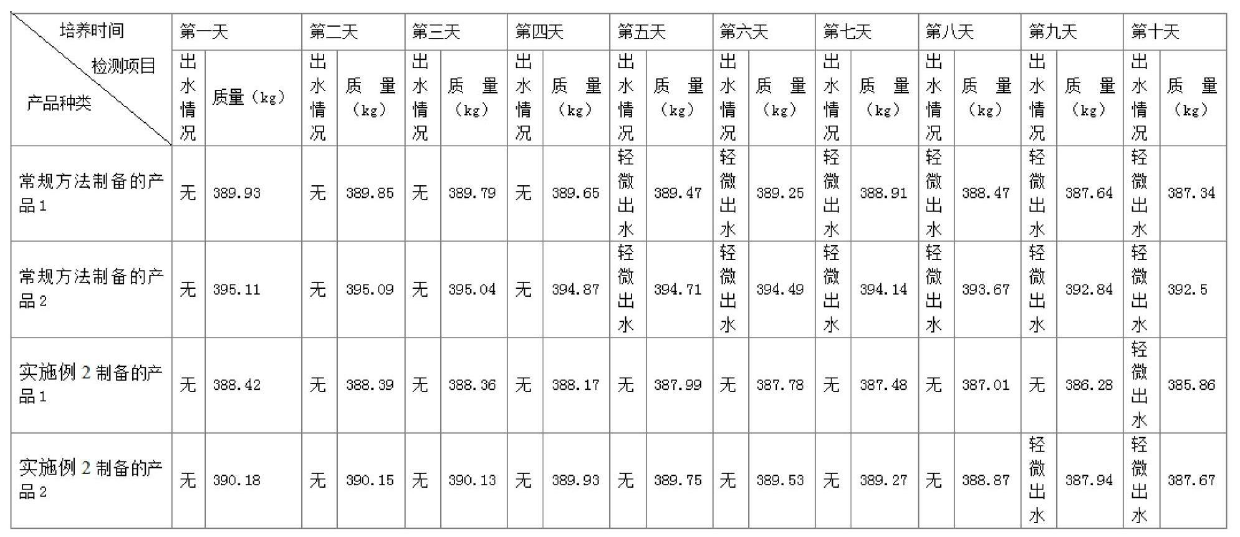

[0018] 70kg of raw meat is thawed→minced→stirred→marinated→chopped (add 1.44kg of carrageenan)→enema→cooked and sterilized→cooled→finished product inspection→labeling→storage and storage. The whole processing process is high-temperature ham sausage finished product.

Embodiment 2

[0020] Take 50kg of dried Eucheuma, rinse it with clean water, put it in 1000L water, add 10kg of sodium hydroxide, 40kg of potassium chloride, soak for 3 hours at 60°C; take out the Eucheuma after soaking, rinse it with clean water, and then put it into the Add 1000L of water to the glue pot, cook at 110°C for 30 minutes; filter while hot after cooking, and the filtrate will become a gelatinous jelly after cooling.

[0021] 70kg of raw meat is thawed → raw material trimming → marinating → chopping (adding 1.58kg carrageenan jelly) → stirring → filling → smoking → cooling → aseptic packaging → secondary sterilization → packaging and warehousing. It is the finished product of low-temperature ham.

Embodiment 3

[0023] Take 50kg of dried Eucheuma, rinse it with clean water, put it in 416L water, add 10kg of sodium hydroxide, 16kg of potassium chloride at the same time, soak for 5 hours at 55°C; take out the Eucheuma after soaking, rinse it with clean water, and then put it Add 250L of water to the glue pot, cook at 80°C for 120 minutes; filter while hot after cooking, and the filtrate turns into a gelatinous jelly after cooling.

[0024] 70kg of raw meat is thawed→minced→stirred→marinated→chopped (add 1.19kg of carrageenan jelly)→enema→cooked and sterilized→cooled→finished product inspection→labeling→storage and storage. The whole processing process is high-temperature ham sausage finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com