Disposable glass magnesium cement building mould plate and method for preparing same

A building formwork and one-off technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of reducing work efficiency, destroying forests, and large construction projects, and achieves simple and easy-to-use methods Convenience, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040]

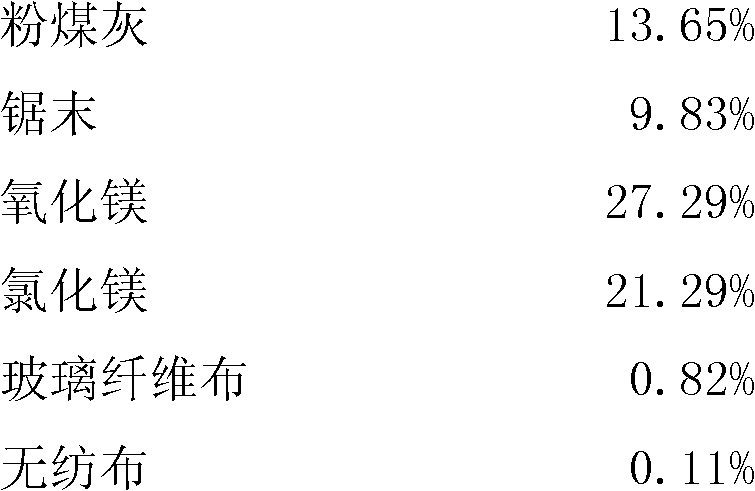

[0041] 1. Prepare magnesia into an aqueous solution of 25 degrees Baume, then put it into the mixer with magnesia, screened sawdust, fly ash and crushed recycled polypropylene, and mix evenly to form a mixed slurry.

[0042] 2. Place a mold with a length of 1300 mm and a width of 3100 mm on the slab processing line, place a layer of non-woven fabric of 10 grams per square meter in the mold, and then place a layer of glass fiber of 150 grams per square meter on the non-woven fabric cloth.

[0043] 3. Adjust the distance between the upper and lower extrusion rollers on the slab processing line to 20 mm.

[0044] 4. Inject the mixed slurry into the mold, and start the slab processing line. While the extrusion roller is pressing down, lay a layer of 150 grams per square meter of glass fiber cloth and a layer of 10 grams per square meter of non-woven fabric at one time on the surface of the mixed slurry.

[0045] 5. The extruded slab is connected to the mold and moved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com