Water paint production wastewater retreatment method

A technology for water-based paint and production wastewater, which is applied in waste paint treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

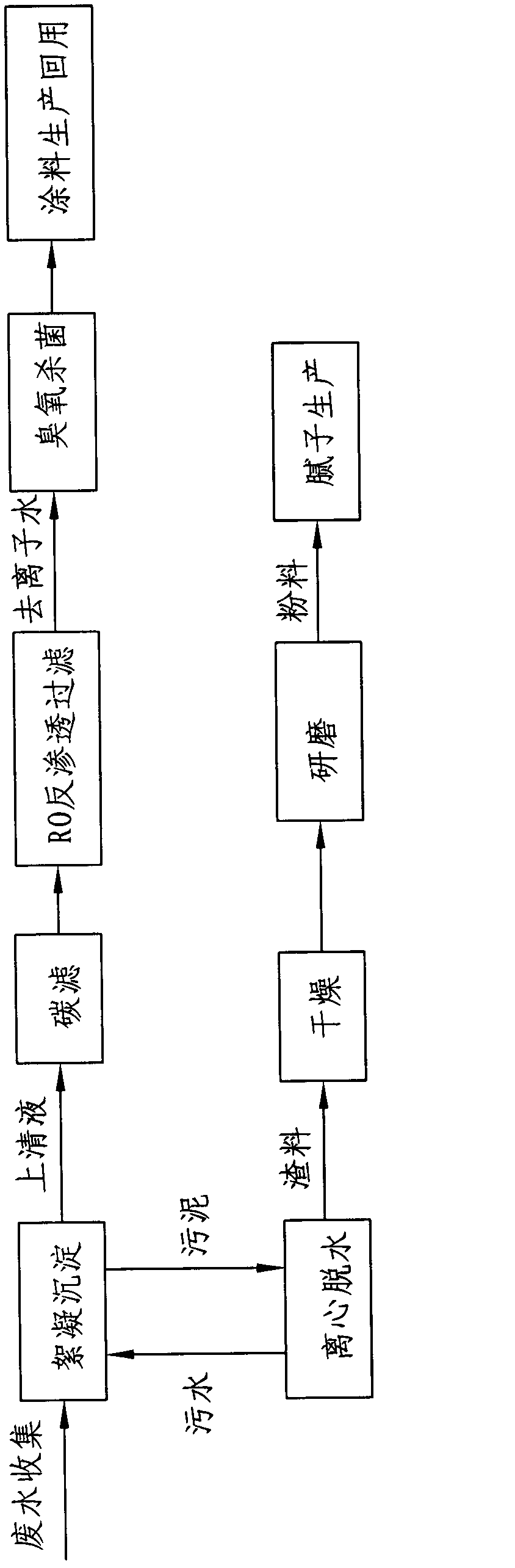

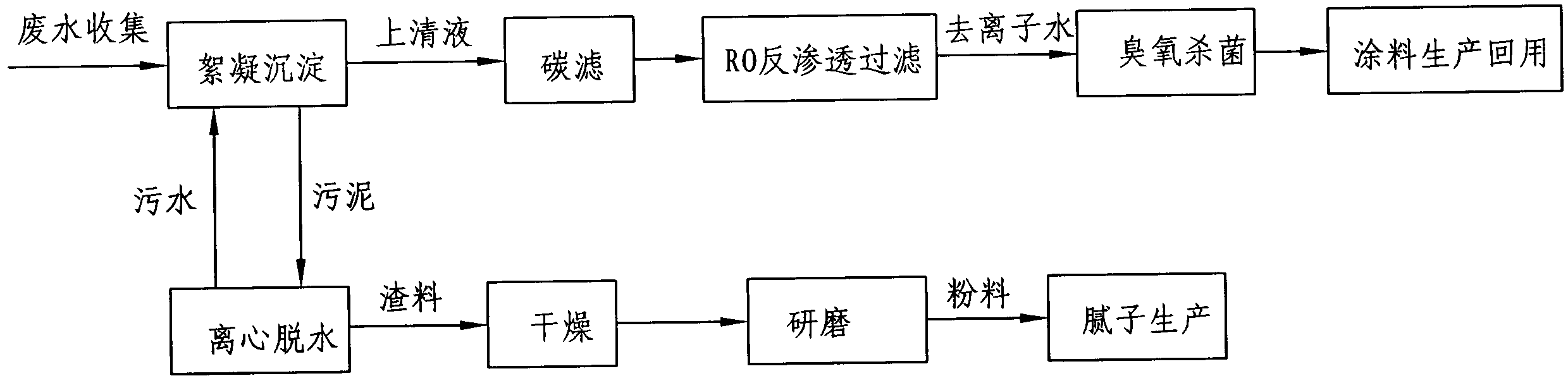

[0008] Such as figure 1 As shown, a water-based paint production wastewater reprocessing method, the first step: add sewage into the sewage sedimentation tank, then add polyaluminum chloride with a sewage weight of 0.1-0.3‰, turn on the air pump and blow and stir for 20 to 40 minutes The second step: After the floating particles in the sewage are stable, slowly add a polyacrylamide solution with a weight of 0.25-0.75% of the sewage weight and a concentration of 0.5-1.5‰, so that the floating particles in the sewage are fully flocculated and the water is clear and transparent; Step 3: After 12 hours of static storage, filter the supernatant in the sewage through an activated carbon filter, collect the water after primary filtration in a PP storage tank, and perform fine filtration through a RO reverse osmosis membrane pure water system; the fourth step : The demineralized water after fine filtration is sterilized by ozone for 10 minutes and then used as water-based paint produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com