High-speed precision dividing and cutting machine for slate

A technology of slitting machine and slate, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problem of unbalanced definition of processing cost and energy saving, and achieve fast cutting speed, small vibration and high cutting accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

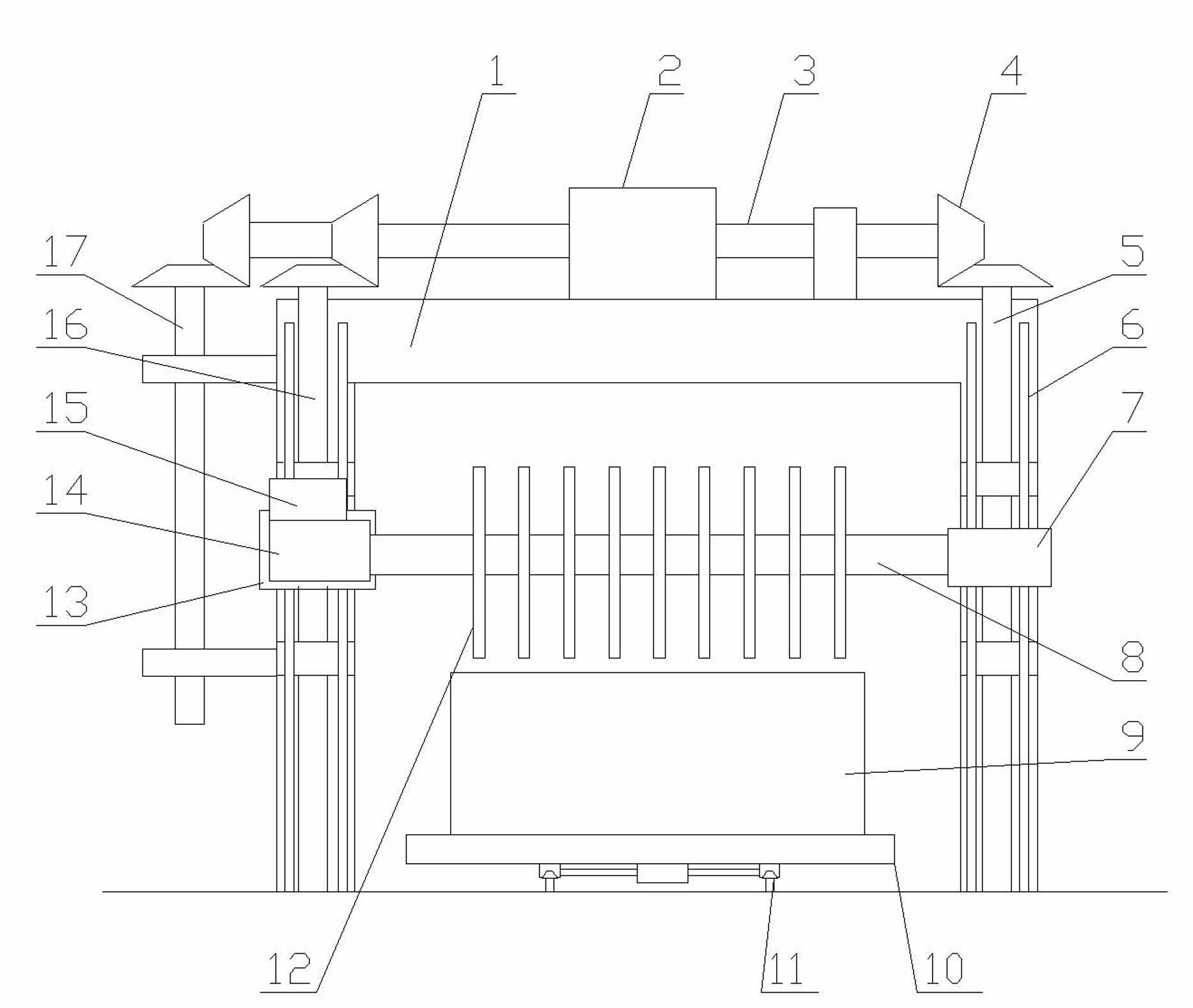

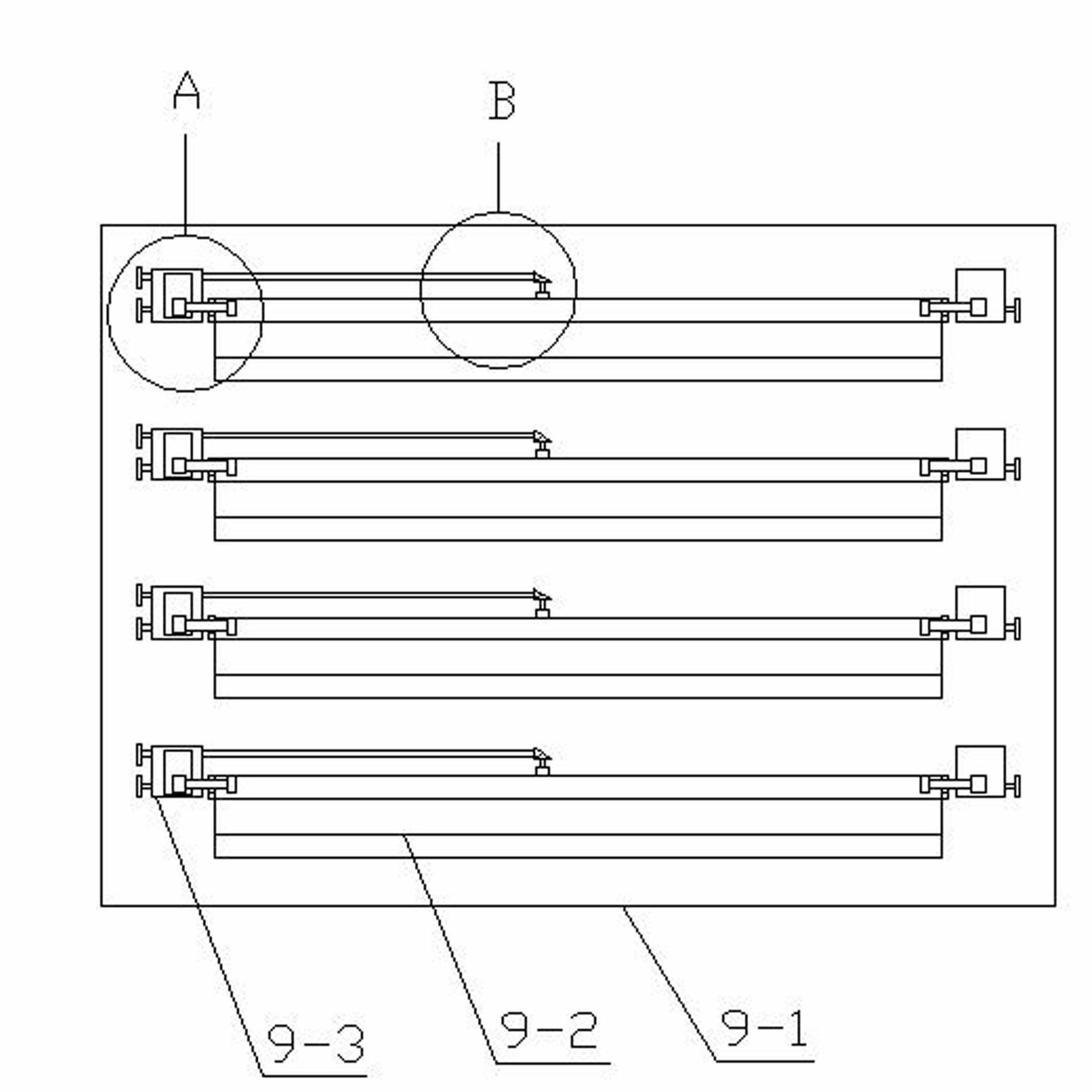

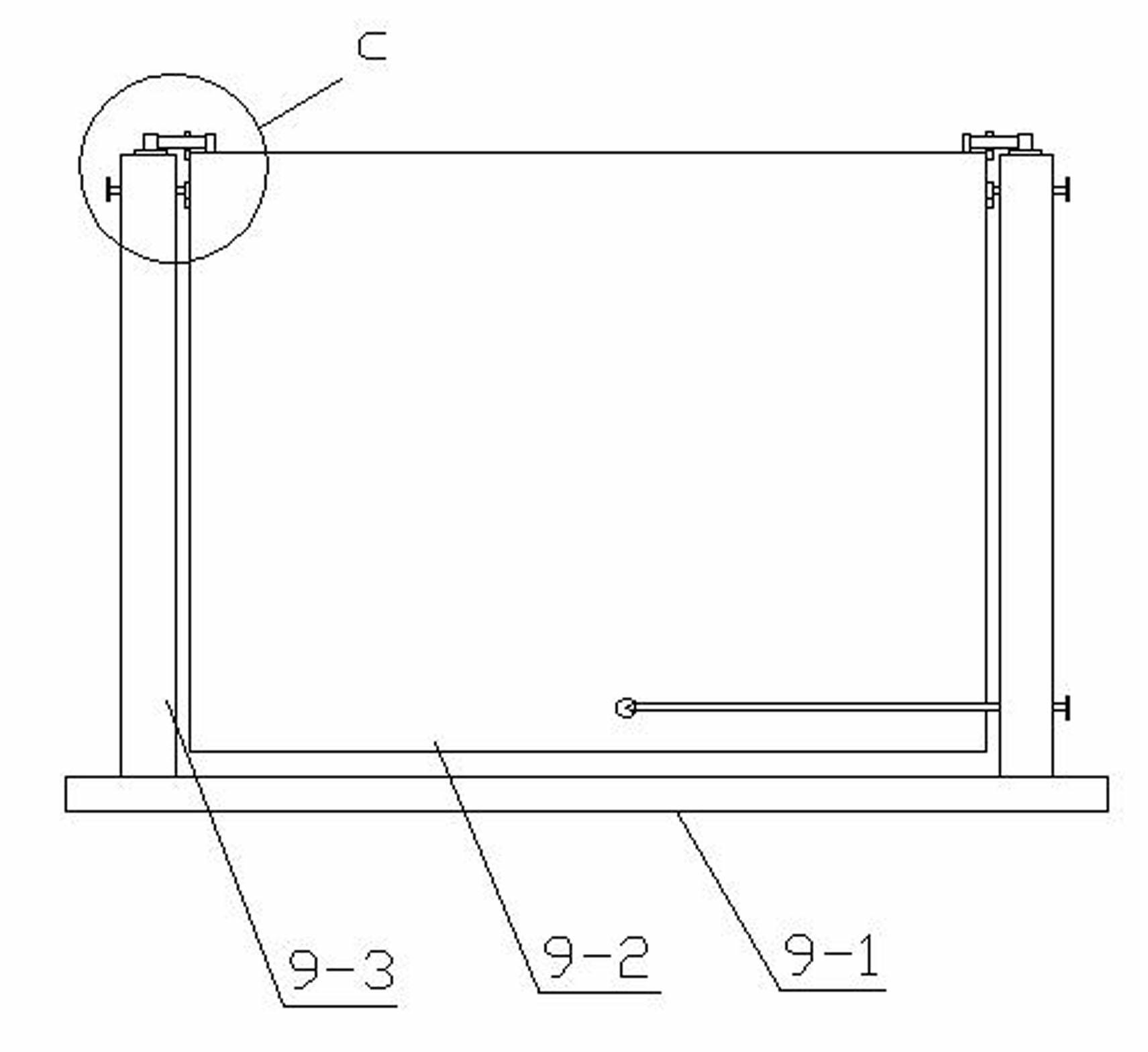

[0020] Such as figure 1 A slate high-speed precision slitting machine shown includes a gantry 1, a cutting saw, a material rack 9, a loading vehicle 10 and a ground guide rail 11, the ground guide rail 11 is arranged on the ground below the gantry 1, and the material rack 9 is set On the material loading vehicle 10 , the material loading vehicle 10 is arranged on the ground guide rail 11 , and the material loading vehicle 10 is provided with a motor for driving the material loading vehicle 10 to move on the ground guide rail 11 .

[0021] Both columns of the gantry 1 are provided with vertical guide rails 6, the vertical guide rail 6 on the right side is provided with a slide block 7, the vertical guide rail 6 on the left side is provided with a slide block 13, and the slide block 13 is fixed with a The motor 15 and the speed reducer 14, the speed reducer 14 is connected with the motor 15. The cutting saw includes a main shaft 8 and a plurality of spaced apart saw blades 12 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com