Press line automatic tapping process and processing system thereof

A processing system, punching line technology, applied in the direction of manufacturing tools, metal processing equipment, tangent devices, etc., can solve the problems of insufficiency, less product attack, missed attack, etc., to ensure product quality, improve production efficiency, and avoid negligence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

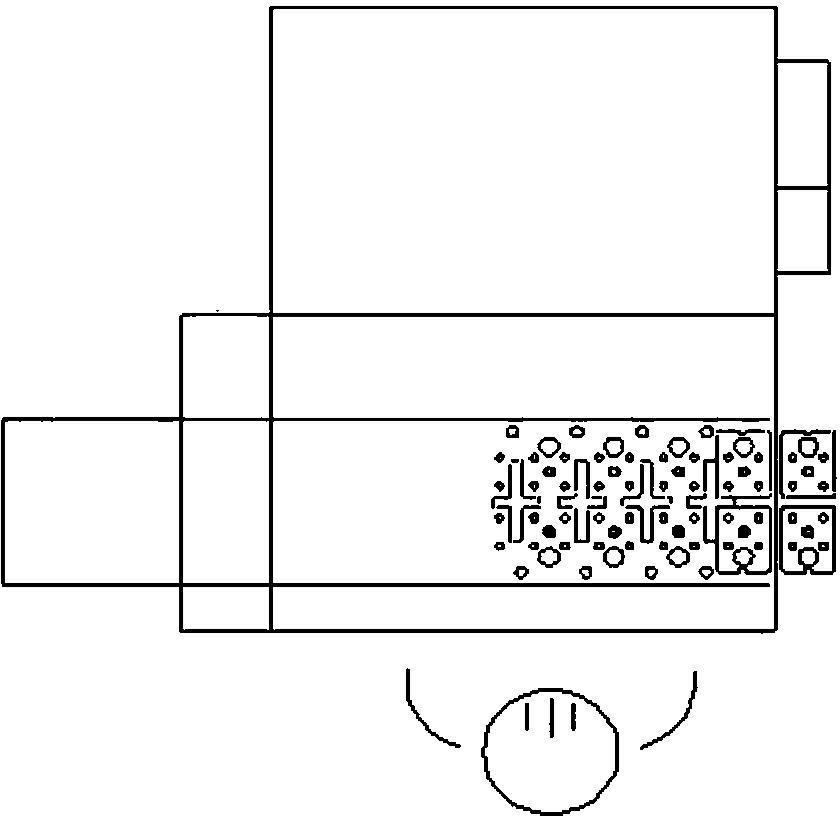

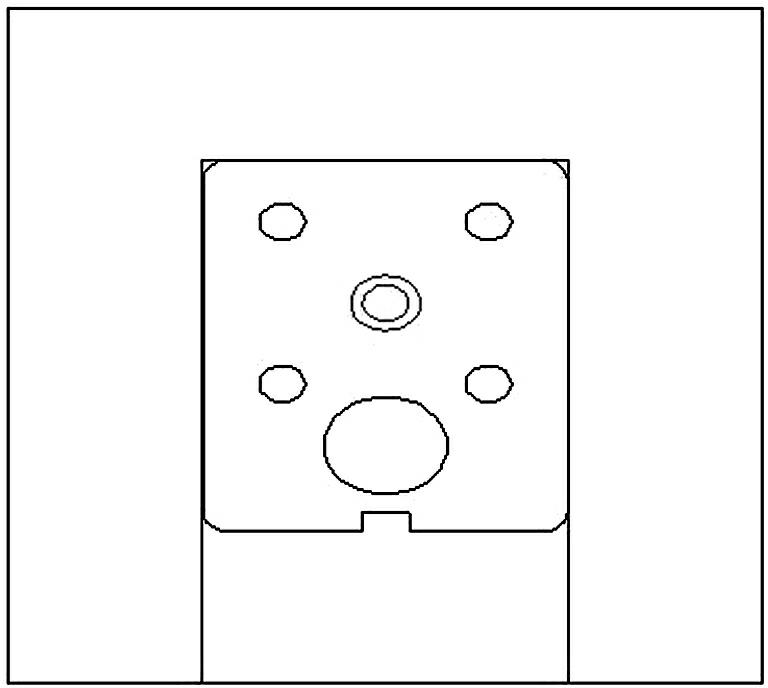

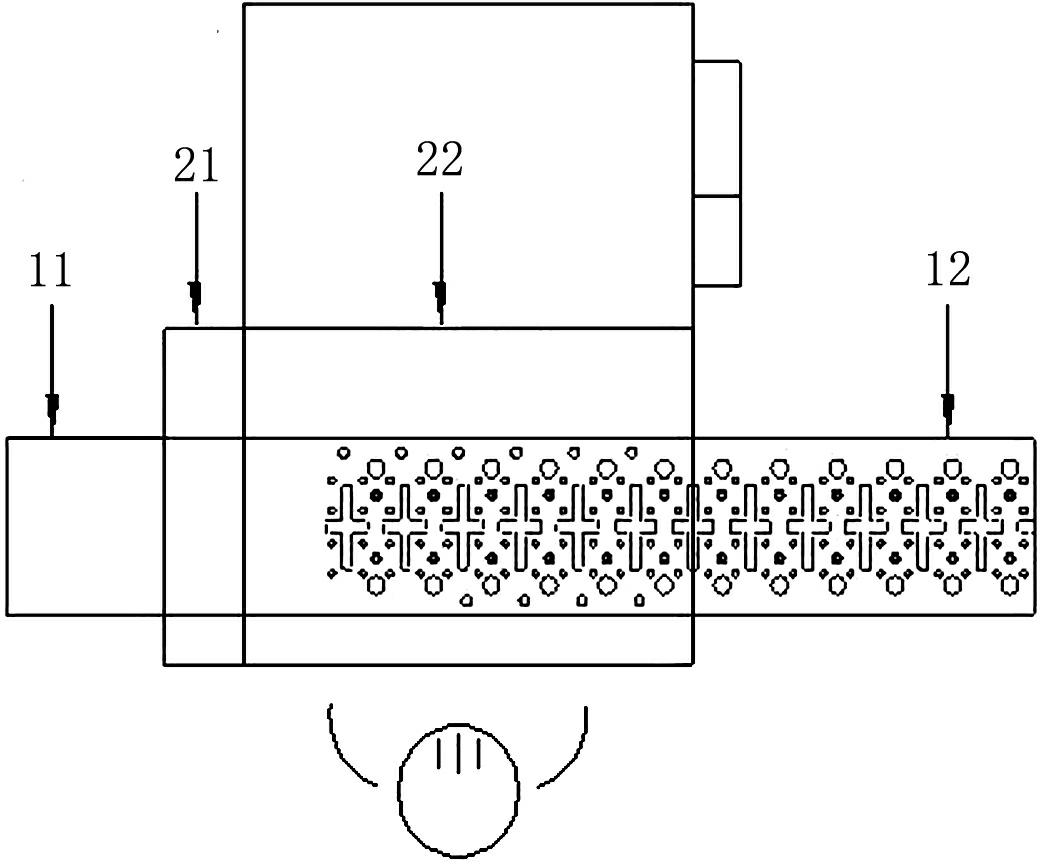

[0027] Such as Figure 3 to Figure 6 As shown, the automatic tapping process of the stamping line of the present invention punches out workpieces with corresponding shapes and lines according to the design requirements of the drawings, and taps at the designated position 33, specifically comprising the following steps:

[0028] Step S1, stamping forming: select the stamping forming equipment 22 and the stamping die according to the processing design, set the feeding step distance of the first stamping feeding device 21, and carry out the material strip 11 fed by the first stamping feeding device 21 in the stamping forming equipment 22 Stamping processing. The stamped material strip is a semi-finished product, and the guide hole and positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com