Novel processing technique of reinforcing steel bar cutting machine shell

A steel bar cutting machine and processing technology, which is applied in the field of mechanical processing and manufacturing, can solve the problems of inability to carry out large-scale and large-scale production, the inability to find and replace the cutter head in time, and the complex structure of the cutting machine shell, so as to promote sustainable development. Development, firmness and resistance to violence Increased strength, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

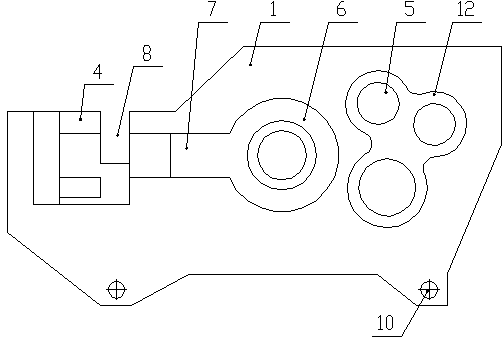

[0023] like Figure 1 to Figure 5 As shown, a novel processing technology of a steel bar cutting machine housing of the present invention comprises the following steps:

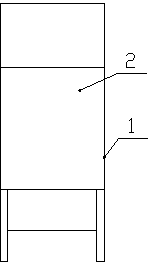

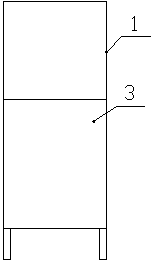

[0024] (1) Divide the shell into two facade panels 1, a front closure panel 2 located at the front ends of the two facade panels 1, a rear closure panel 3 located at the rear ends of the two facade panels 1, and a rear closure panel 3 located at the two facade panels 1. A bottom closing plate 9 at the bottom end of the panel 1, two inner holding force weighting plates 11 positioned on the inner sides of the two vertical panels 1, two outer holding force weighting plates 12 positioned on the outer sides of the two vertical panels 1 and A fixed knife part 4 located at the upper part of the front side of the two facade panels 1;

[0025] (2) For two vertical panels 1, a front closing panel 2, a rear closing panel 3, a bottom closing panel 9, two inner holding force weighting plates 11, two outer holding force w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com