Sealing device for laser cutting machines

A laser cutting machine and sealing device technology, which is applied to laser parts, laser welding equipment, manufacturing tools, etc., can solve problems such as increased maintenance and repair costs, equipment downtime losses, and human health damage, and achieves good smoke and dust prevention effects. Installation Easy to adjust, light leakage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

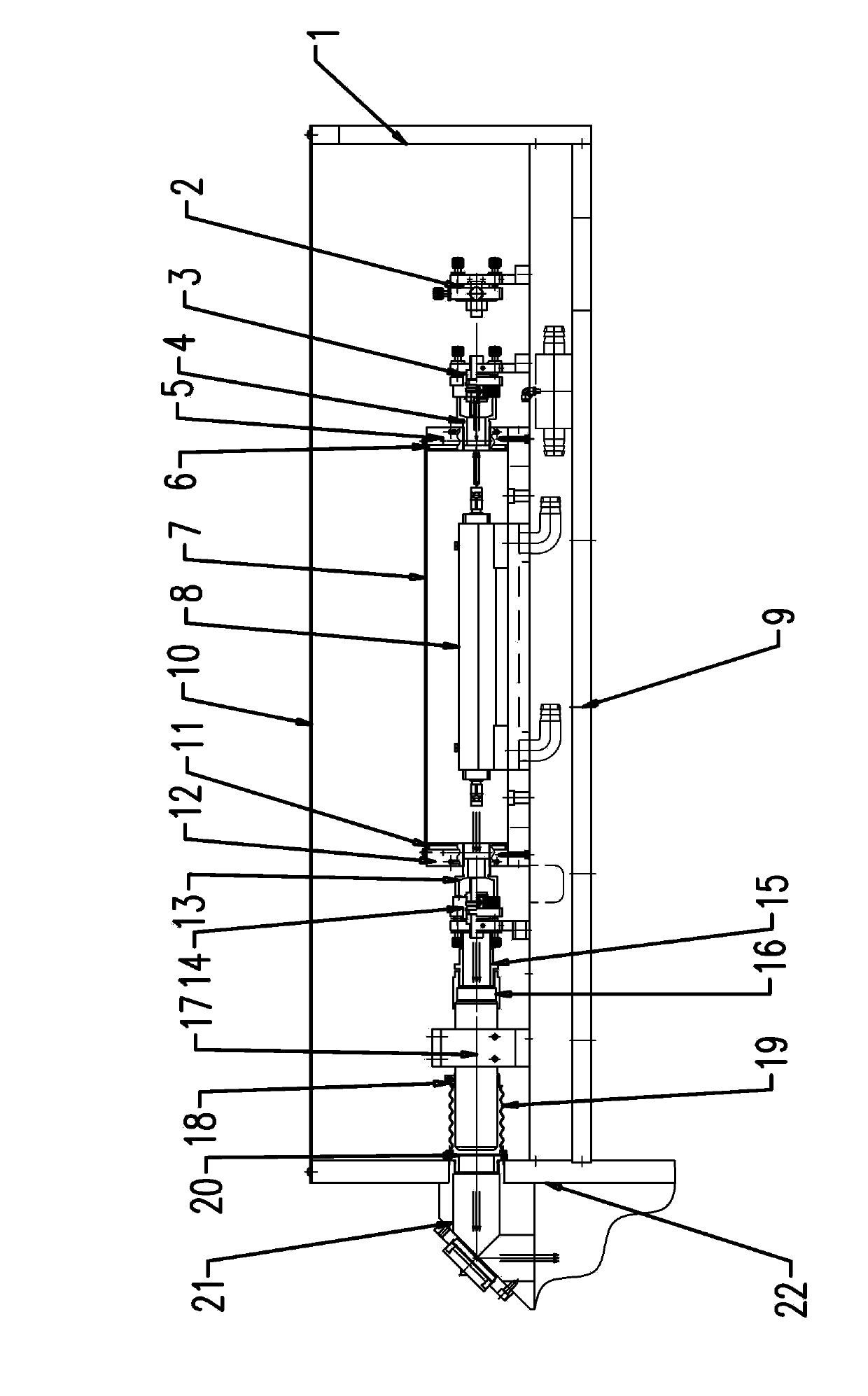

[0019] Such as figure 1 As shown, the present invention mainly includes a rear vertical plate 1, a red light seat 2, a full reflection mirror seat 3, a rear sealing cover 4 of the light exit cavity, a rear vertical plate 5 of the light concentrating cavity, an inner layer cover 7 of the light concentrating cavity, and a laser generator 8 , Base 9, Outer Cover 10, Front Riser 12 of Concentrating Cavity, Front Sealing Cover 13 of Light Outlet Cavity, Half-mirror Base 14, Front A Cover 15 of Beam Expander, Front B Cover 16 of Beam Expander, Beam Expander 17. Tube clamp 18, rear A cover 19 of beam expander, rear B cover 20 of beam expander, total reflection mirror bracket 21 and front vertical plate 22.

[0020] The laser generator 8 is installed on the base 9, the inner layer cover 7 of the light focusing cavity is covered on the laser generator 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com