Method for controlling side waves of hot rolling strip steel

A technology of hot-rolled strip steel and control method, which is applied in the fields of flatness control of hot-rolled strip steel products and side wave control of hot-rolled strip steel, can solve problems that have not been applied, and achieve improvement of side wave defects, The effect of improving the quality of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

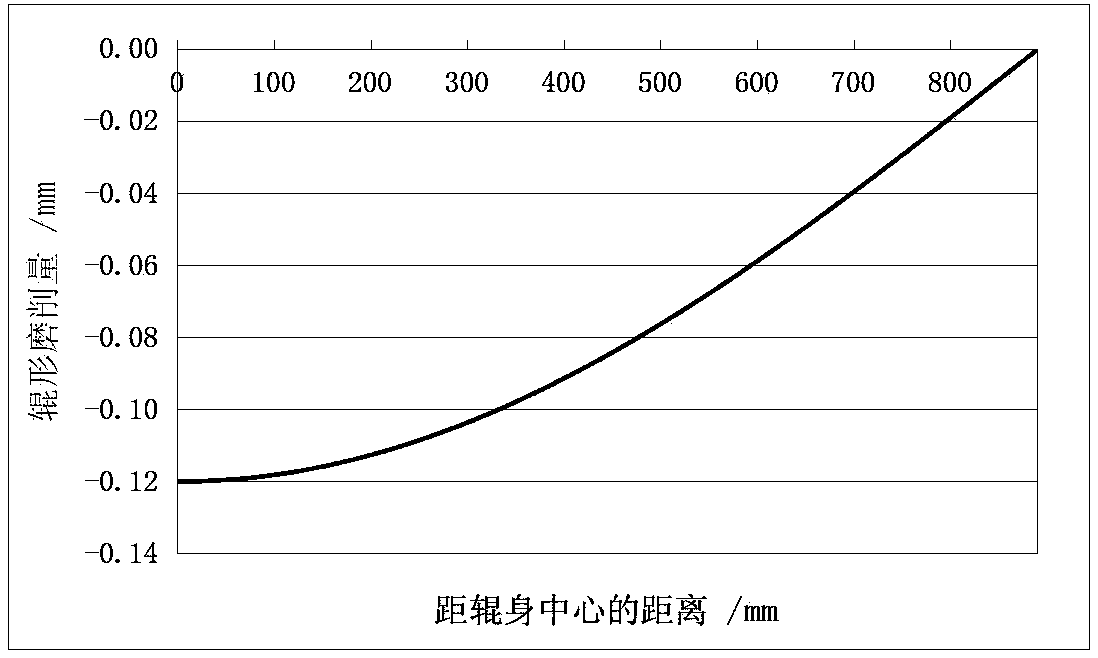

[0070] The grinding curve of the original work roll is a sinusoidal curve with a crown of -0.1mm and a roll body length of 1780mm. According to the off-line detection results, determine that the side wave position is within the range of 200mm to 400mm from the center of the strip steel, that is, x 1 200mm, x 2 It is 400mm, and the side wave of hot-rolled strip steel is 1.6% (wave height / wavelength). Determining the maximum roll shape correction c needed to control side waves using an offline simulation tool x is 8 μm. According to the formulas (1)~(6), we can get:

[0071] The initial grinding curve of the work roll is:

[0072] y = - 0.1 × sin [ π 2 ( 1780 - x 1780 ) ] , 0 ≤ x ≤ ...

Embodiment 2

[0080] The grinding curve of the original work roll is a sinusoidal curve, the crown of the work roll is 0.1mm, and the length of the roll body is 2000mm. According to the off-line detection results, determine that the position of the side wave is within the range of 100mm to 500mm from the center of the strip steel, that is, x 1 100mm, x 2 It is 500mm, and the side wave of hot-rolled strip steel is 2.2% (wave height / wavelength). Determining the maximum roll shape correction c needed to control side waves using an offline simulation tool x is 12 μm.

[0081] According to the formulas (1)~(6), we can get:

[0082] The initial grinding curve of the work roll is:

[0083] y = 0.1 × sin [ π 2 ( 2000 - x 2000 ) ] , 0 ...

Embodiment 3

[0091] The grinding curve of the original work roll is a sinusoidal curve with a crown of -0.15m and a roll body length of 1500mm. According to the off-line detection results, determine that the side wave position is within the range of 200mm to 600mm from the center of the strip steel, that is, x 1 200mm, x 2 is 600mm, and the side wave is 2.8% (wave height / wavelength). Determining the roll shape correction c needed to control side waves using an offline simulation tool x is 15 μm.

[0092] According to the formulas (1)~(6), we can get:

[0093] The initial grinding curve of the work roll is:

[0094] y = - 0.15 × sin [ π 2 ( 1500 - x 1500 ) ] , 0 ≤ x ≤ 200,400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com