Method and apparatus for realizing automatic control of milling and plaing work and work speed for milling and planing machine

A technology of working speed and milling machine, applied in the control field of milling, can solve the problems of sudden increase in the working torque of the milling drum, damage to the components of the working device, incompatibility, etc., so as to improve the construction efficiency, improve the quality, and prevent the boring car. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

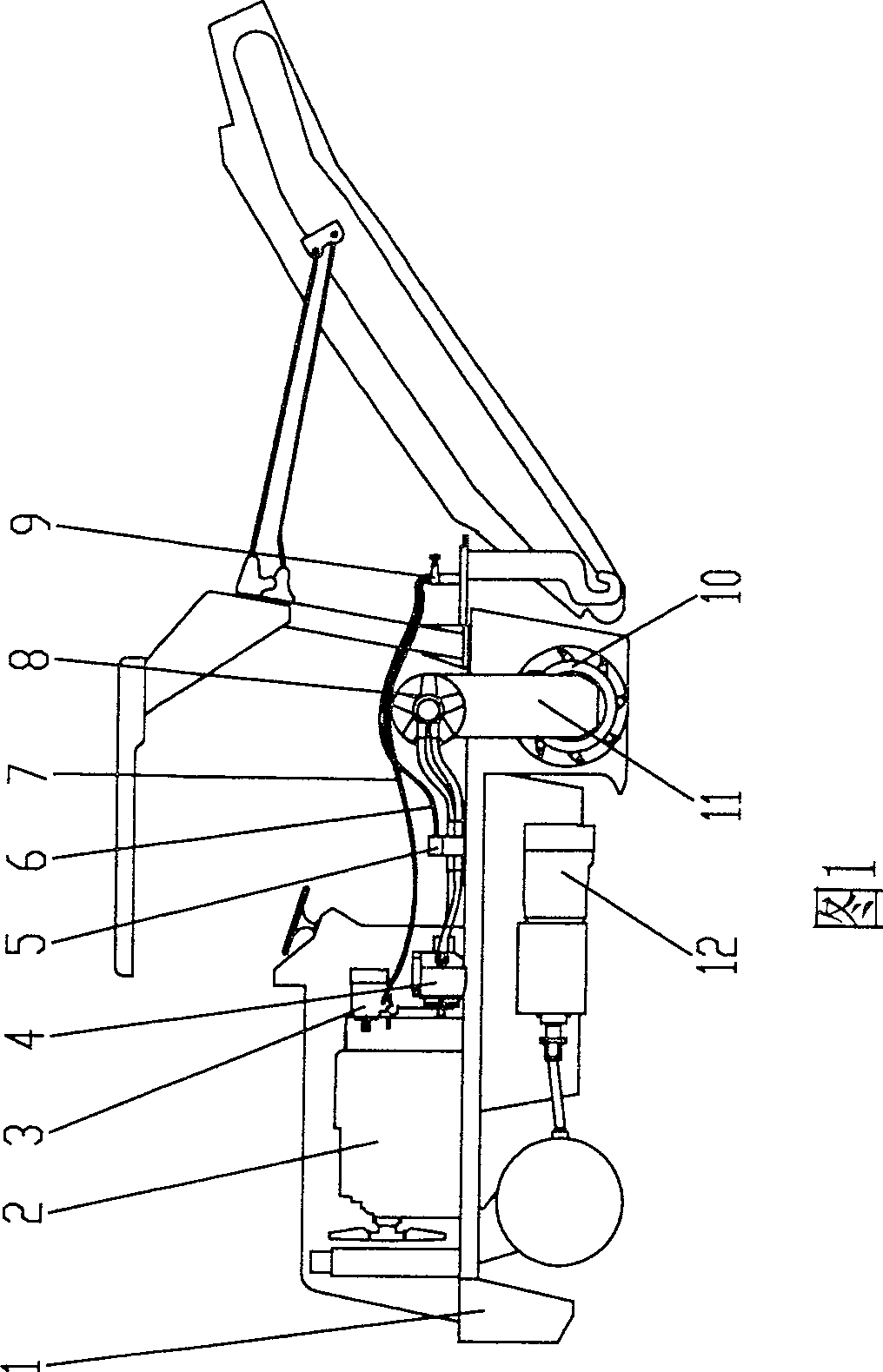

[0015] The structure of an embodiment of the device for realizing the milling work of the milling machine and the automatic control of the working speed of the present invention is shown in FIG. 1 . Engine 2, driving pump with servo valve 3, working pump with servo valve 4, high pressure valve of working pump 5, low pressure pipeline 6, high pressure pipeline 7, working hydraulic motor 8 are installed on the frame 1 of the device , overflow valve 9 and sprocket wheel case 11, the milling drum 10 of driving hydraulic motor 12 and band milling cutter head is installed on the bottom of frame 1. The travel hydraulic motor 12 drives the wheels. The main shaft of the engine 2 drives the main shaft of the driving pump 3 and the main shaft of the working pump 4 through the transmission parts respectively. The working hydraulic motor 8 is installed above the sprocket box 11, and the power is transmitted to the milling drum 10 through a chain transmission.

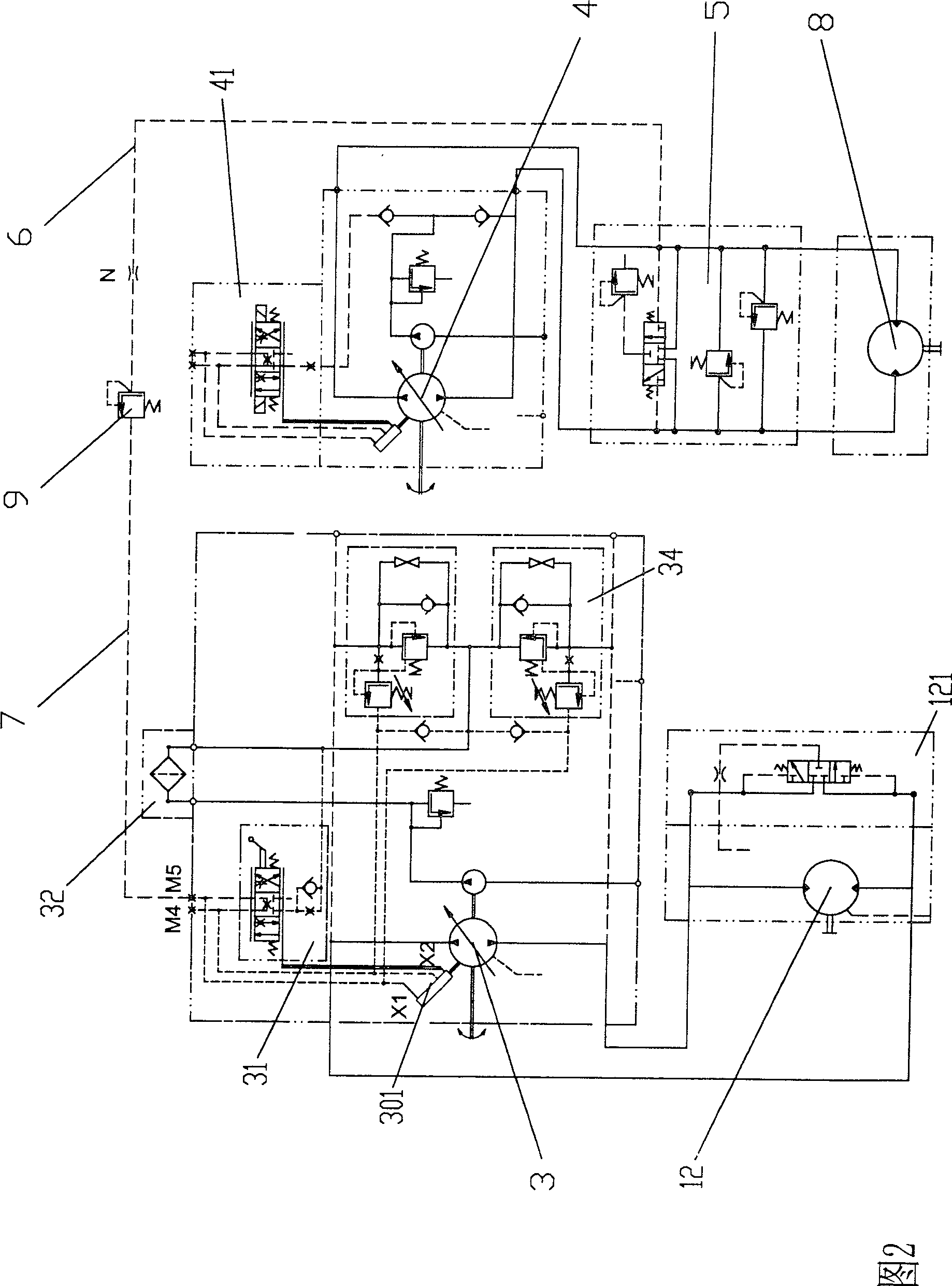

[0016] Please refer to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com