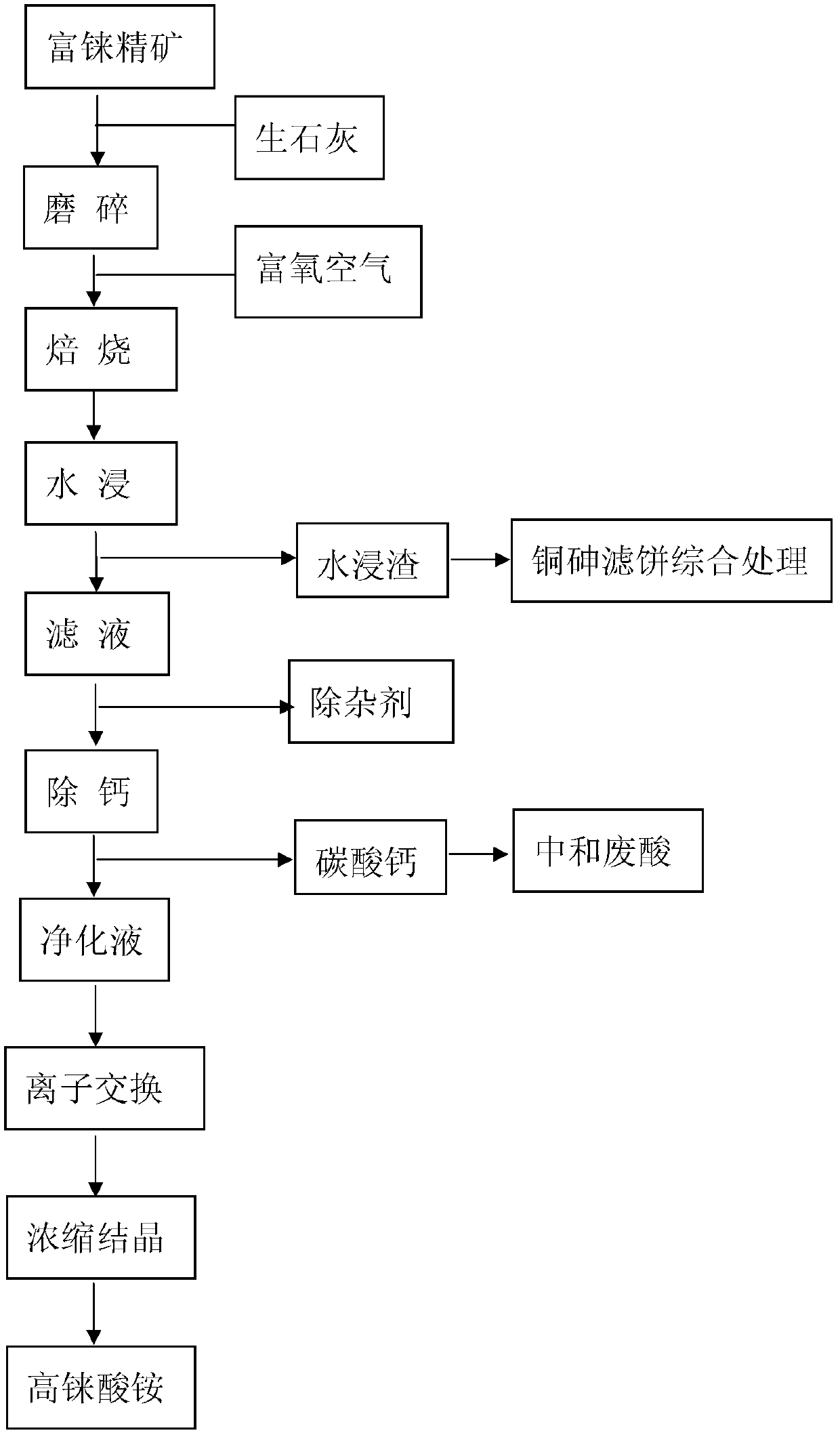

Method for extracting rhenium from rhenium-rich concentrates

A technology of concentrated ore and oxygen-enriched air, which is applied in the direction of improving process efficiency, can solve the problems of easy crystallization of calcium ions, unreported treatment, unfavorable separation and purification, etc., and achieve high recovery rate of rhenium, which is conducive to industrial application and effective thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Oxygen-enriched roasting

[0057] Take 1 kg of rhenium-rich concentrate, the main components of rhenium-rich concentrate are: Re3.5%, As8%, Cu13%, S65%. The rhenium-rich concentrate and quicklime are mixed and ground to 100 mesh, and the amount of quicklime added is 0.5 times the quality of the concentrate, that is, 0.5 kg. Add the mixture into the electric furnace, pass oxygen-enriched air, the gas oxygen content volume ratio is 50%, the pressure is 0.3Mpa, and the gas consumption is 0.7Nm 3 , calcination temperature 550 ℃, calcination time 6h.

[0058] (2) Water leaching

[0059] The roasted material is directly added to the reaction vessel, leached with water slurry, the liquid-solid ratio is 5, the leaching temperature is 60°C, and the leaching time is 5h. After the leaching is completed, filter and separate the solid and liquid, and the solid slag with high arsenic content is combined with the copper and arsenic filter cake for unified treatment. The main c...

Embodiment 2

[0065] (1) Oxygen-enriched roasting

[0066] Take 1 kg of rhenium-rich concentrate, the main components of rhenium-rich concentrate are: Re5.4%, As10%, Cu15%, S59.7%. The rhenium-rich concentrate and quicklime are mixed and ground to 100 mesh, and the amount of quicklime added is 1 times the quality of the concentrate, that is, 1 kg. Add the mixture into the electric furnace, pass oxygen-enriched air, the gas oxygen content volume ratio is 70%, the pressure is 0.4Mpa, and the gas consumption is 0.6Nm 3 , calcination temperature 700 ℃, calcination time 4h.

[0067] (2) Water leaching

[0068] The roasted material is directly added to the reaction vessel, leached with water slurry, the liquid-solid ratio is 5, the leaching temperature is 80°C, and the leaching time is 3h. After the leaching is completed, filter and separate the solid and liquid, and the solid slag with high arsenic content is combined with the copper and arsenic filter cake for unified treatment. The main co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com