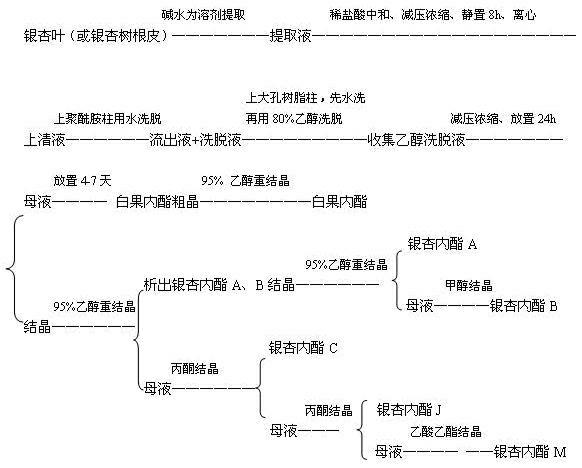

Process for extraction and separation of ginkgolides A, B, C, J, M and bilobalide

A technology of ginkgolide and bilobalide, which is applied in the field of B, extraction and separation of ginkgolides A, J, C, M and bilobalide, can solve the problems of complex process, low purity and low yield, and achieve High yield and purity, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Ginkgo biloba as raw material

[0025] Take 200 kg of ginkgo leaves, add 2000 kg of weakly alkaline water (PH=8), heat and boil for 3 hours, filter, add 2000 kg of weakly alkaline water to the residue, heat and boil for 3 hours, filter, combine the filtrate, dilute Hydrochloric acid was neutralized to neutral, concentrated under reduced pressure to 1 / 3 volume, stood still for 8 hours, centrifuged, the supernatant was put on a polyamide resin column, and the effluent was collected, and the column was eluted with deionized water 3 times the volume of the column. The effluent and water eluate are put on a macroporous resin column, the column is first washed with water, and then eluted with 1000 liters of 80% ethanol (the amount of ethanol added is 3-5 times the volume of the column), and the ethanol eluate is concentrated under reduced pressure to 12 Liter (the ethanol eluate is concentrated to a volume-to-weight ratio of 1 / 15 to 1 / 25 of Ginkgo biloba, that is, 15KG crude ...

Embodiment 2

[0028] Ginkgo biloba root bark as raw material

[0029] Take 100 kg of ginkgo root bark, add 1000 kg of weak alkaline water (PH=8), heat and extract for 3 hours, filter, continue to add 1000 kg of weak alkaline water to the residue, heat and extract for 3 hours, filter, combine the filtrate, dilute hydrochloric acid Neutralize to neutral, concentrate under reduced pressure to 1 / 3 volume, let stand for 8 hours, centrifuge, put the supernatant on a polyamide resin column, collect the effluent, elute the column with deionized water 3 times the volume of the column, and flow out liquid and water eluent on the macroporous resin column, the column was washed with water earlier, and then eluted with 1000 liters of 80% ethanol, and the ethanol eluent was concentrated to 12 liters under reduced pressure (the ethanol eluent was concentrated to the volume and weight of Ginkgo biloba The ratio is 1 / 15 to 1 / 25, that is, 15KG crude drug - Ginkgo biloba, ethanol eluate is concentrated to 1 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com