Modified active carbon and method for removing ammonia gas in intensive livestock farm

A technology of activated carbon and modification, which is applied in the field of air purification to achieve the effect of large adsorption capacity and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

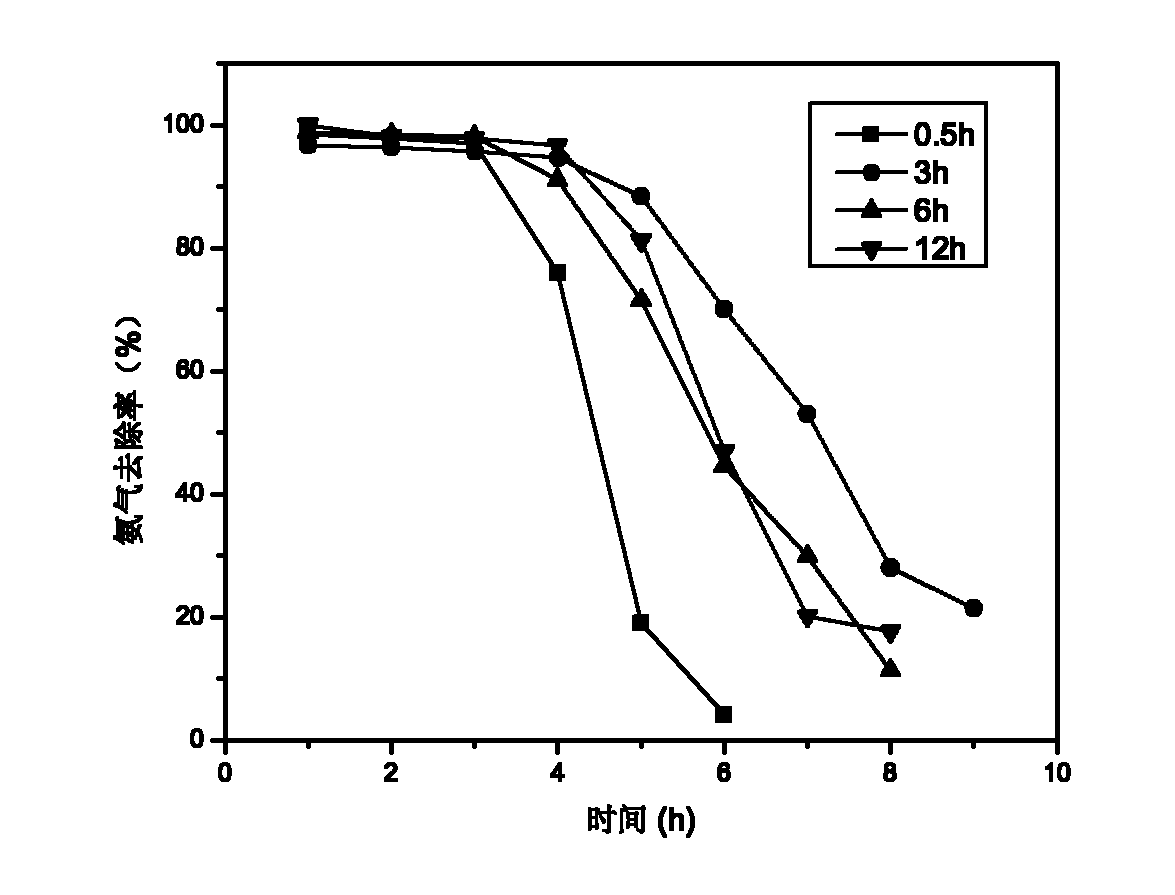

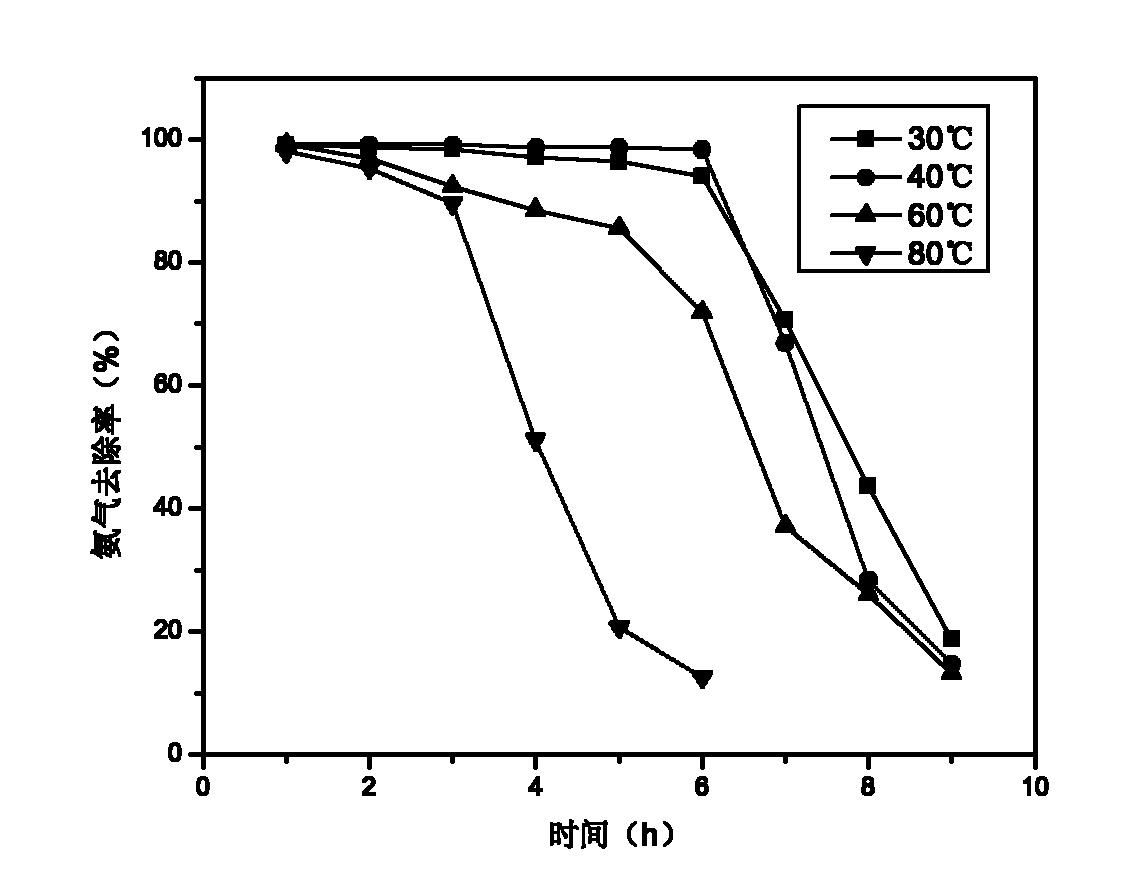

[0059] Measure 20ml of activated carbon, the ratio of activated carbon to water in the high-temperature reactor is 2:3, first modify it in a high-temperature reactor at 300°C for 3 hours, dry it in an oven at 105°C for 3 hours, and then use a mass fraction of 40 % citric acid and copper nitrate solution were impregnated in equal volume at 20°C for 3 hours, the impregnated activated carbon was washed with distilled water until neutral, and then dried in an oven at 105°C for 3 hours, respectively: first GS300 and then 40% lemon acid and first GS300 and then 40% copper nitrate to make multi-step modified activated carbon. Two kinds of modified active carbons that above-mentioned make, at space velocity 900h -1 , Intake concentration 750-850mg / m 3 , respectively investigated their ability to remove ammonia at different temperatures of 30°C, 40°C, 60°C and 80°C, the adsorption curves were as follows figure 2 and image 3 .

Embodiment 2

[0061] According to two kinds of modified activated carbons prepared in Example 1, at a temperature of 30°C and an inlet concentration of 750-850mg / m 3 Next, the space velocity of 300h was investigated respectively -1 ,600h -1 ,900h -1 and 1200h -1 The ability to remove ammonia, the adsorption curves are as follows Figure 4 and Figure 5 .

Embodiment 3

[0063] According to two kinds of modified activated carbons that embodiment 1 makes, at temperature 30 ℃, space velocity 900h -1 Next, the imported concentration of 350-450mg / m3 was investigated respectively. 3 , 550-650mg / m 3 and 750-850mg / m 3 , 950-1050mg / m 3 The ability to remove ammonia, the adsorption curves are as follows Figure 6 and Figure 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com