Laser processing of display components for electronic devices

An electronic equipment and laser technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as difficulty in maintaining manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

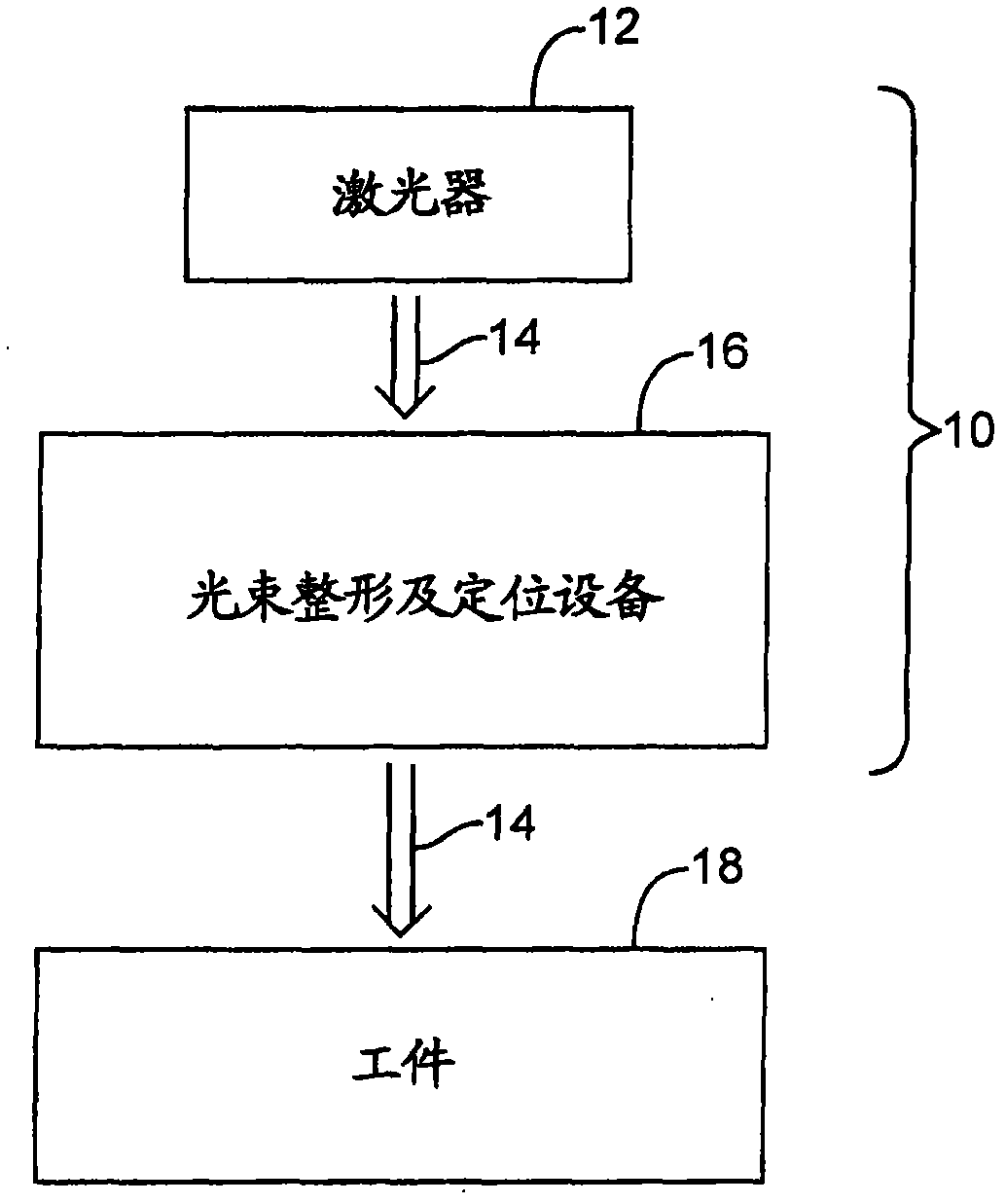

Method used

Image

Examples

Embodiment Construction

[0032] Displays are widely used in electronic devices. For example, displays may be used in computer monitors, laptops, media players, cellular telephones and other handheld devices, tablet computers, televisions, and other devices. Displays may be based on plasma technology, organic light emitting diode technology, liquid crystal structures, etc.

[0033] Displays typically include layers of materials. For example, a liquid crystal display may include a color filter array layer with color filter elements, a thin film transistor layer with thin film transistors for controlling the application of an electric field to the liquid crystal image pixels. A cover sheet layer can be used to cover the display. The cover sheet layer and other display layers such as color filter array layers and thin film transistor layers typically can be formed from glass, but can also be formed from other substrate materials such as polymers if desired.

[0034] Typically there are multiple additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com