Manufacture method of double composite plastic steel composite pipe

A steel-plastic composite pipe and double-composite technology, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of pipelines that cannot be used to transport liquids under pressure, and achieve the effects of saving plastic raw materials, improving road protection, and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

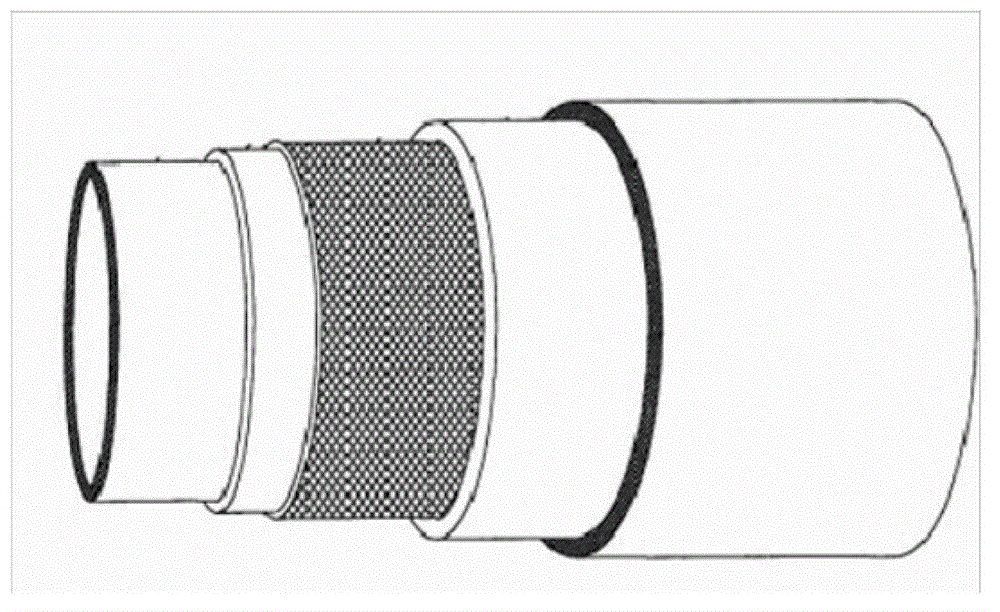

[0041] figure 1 It is a schematic diagram of the traditional steel mesh skeleton tube structure.

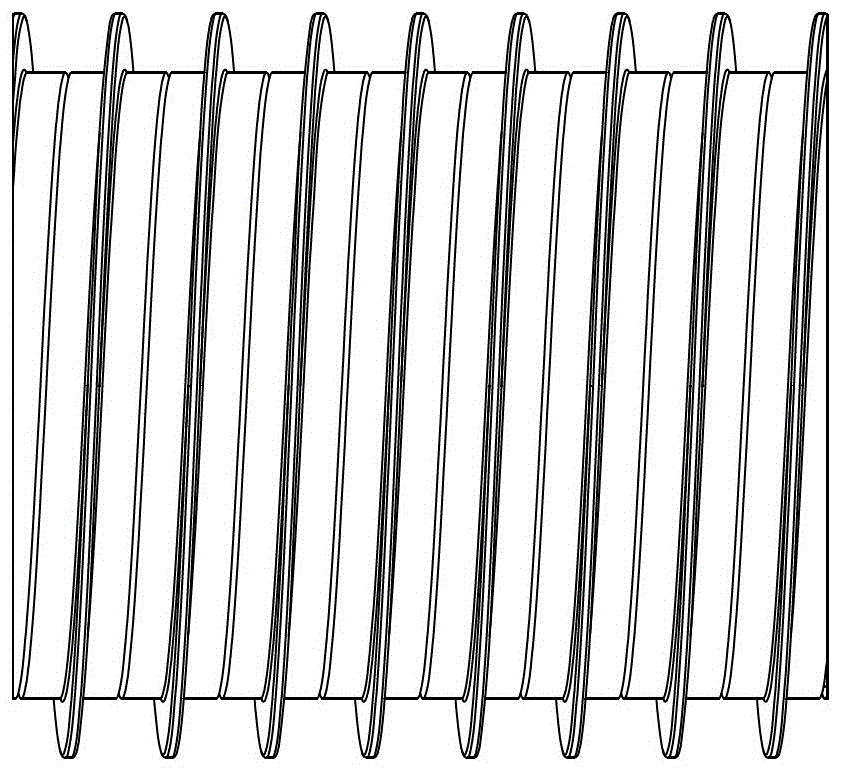

[0042] figure 2 It is a schematic diagram of the structure of a traditional polyethylene plastic-steel winding pipe.

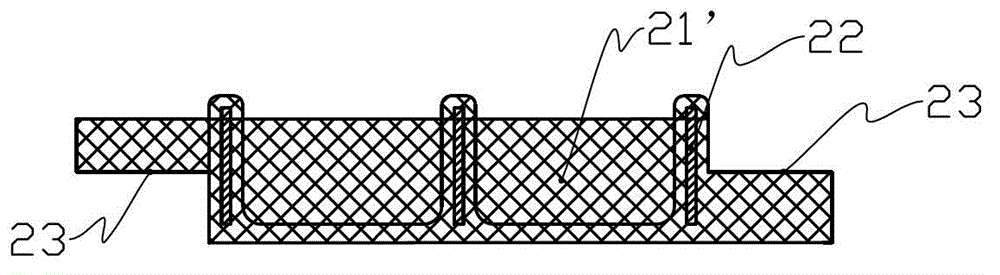

[0043] Such as image 3 Shown, a kind of steel-plastic strip comprises extruded strip body 21', and vertical steel rib 22 is inlaid in the internal rib of strip body, and vertical steel rib is steel belt substantially; The anti-corrosion performance of the plastic and the rigidity of the vertical steel rib are used to ensure the ring rigidity of the buried pipe.

[0044] Simultaneously at the side junction of strip body 21 ', lap joint structure 23 is adopted, so that when adjacent strip bodies are combined, the contact area when the two sides are bonded is greatly increased, and when the pipe is bonded, it is firmer and greatly Improves the joint strength of the pipe.

[0045] Such as Figure 4 as shown,

[0046] A plastic-steel winding pipe base 24 is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com