Multi-stage piston compressor

一种压缩机、活塞式的技术,应用在多级活塞式压缩机领域,能够解决输入压力范围和压缩比窄等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

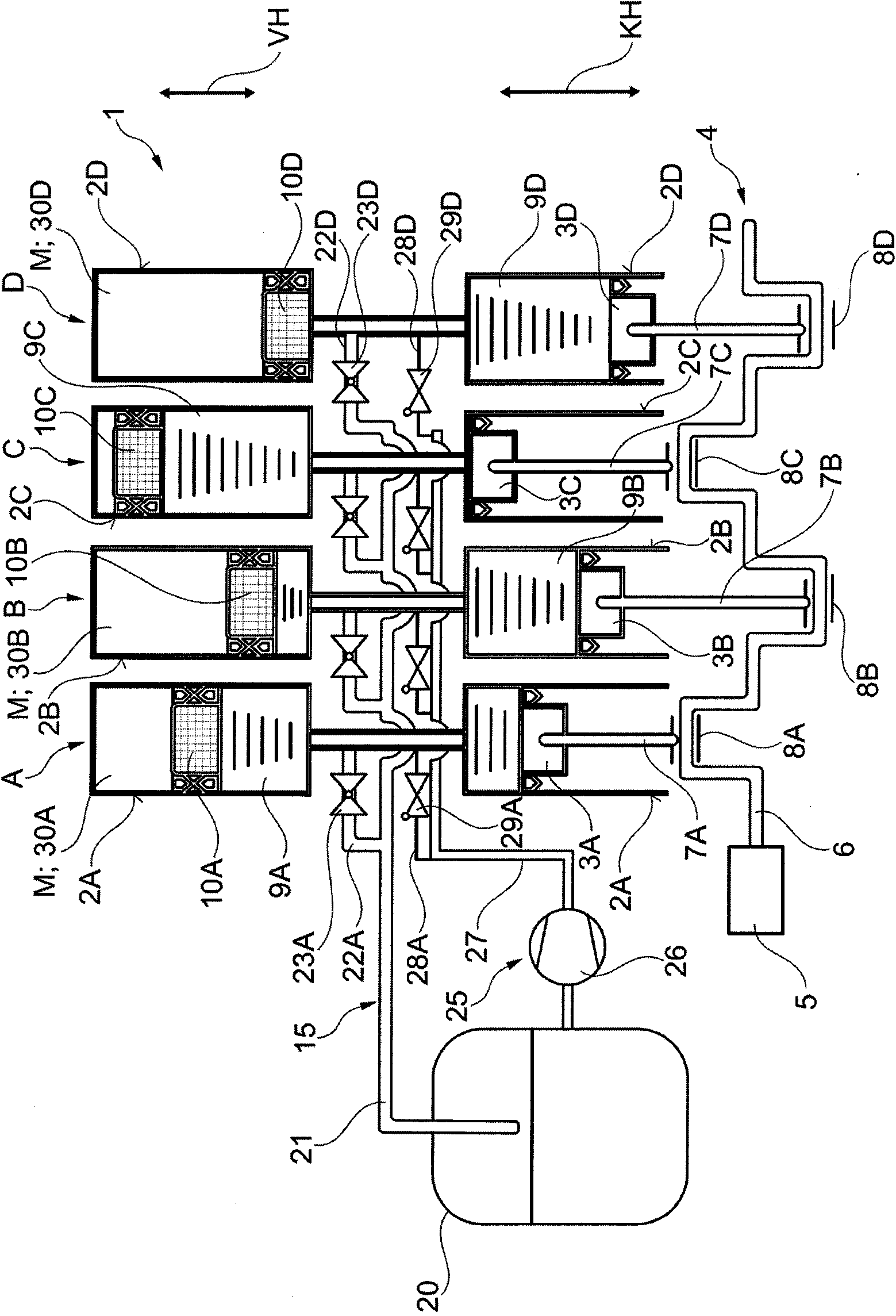

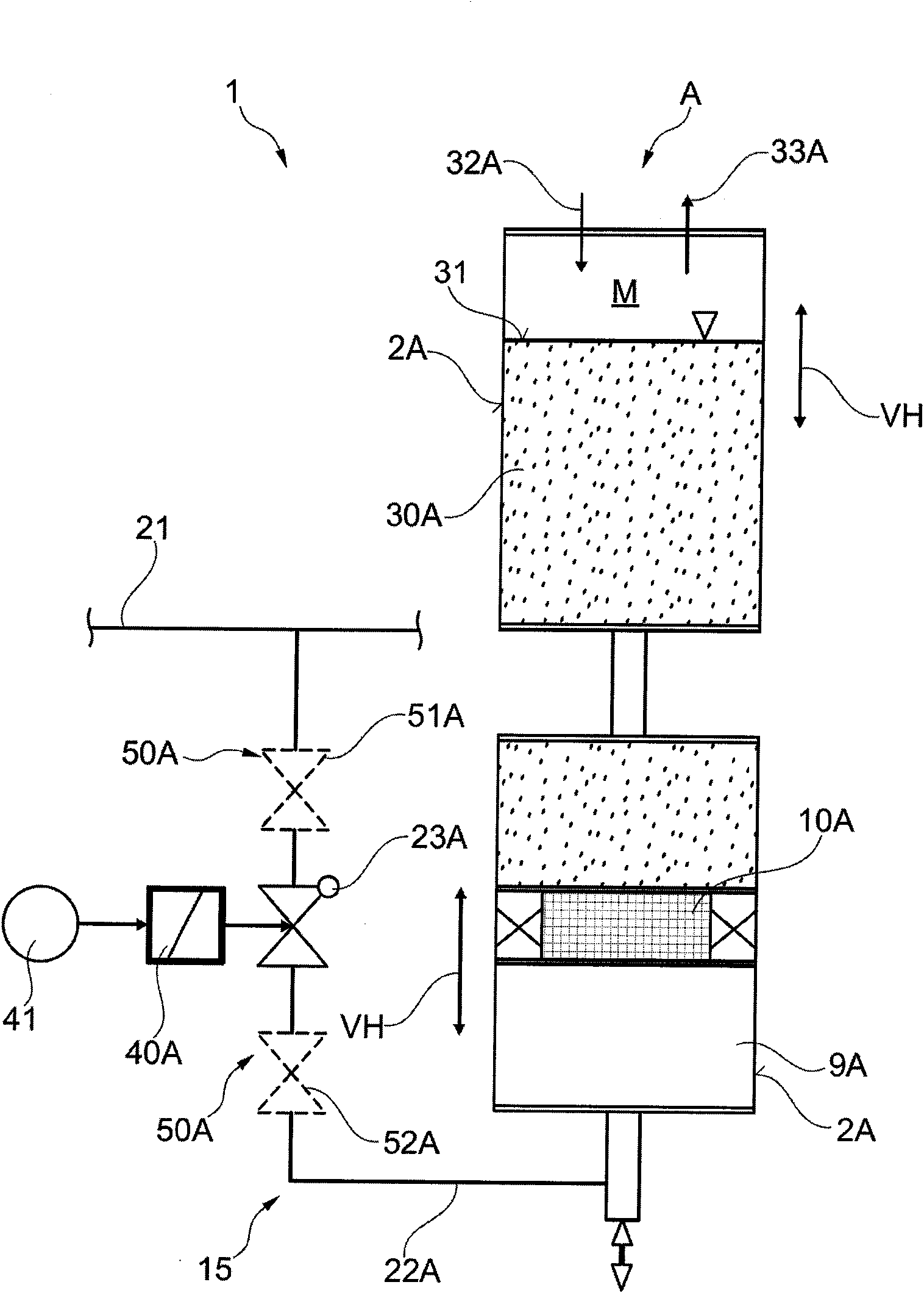

[0028] figure 1 A multi-stage piston compressor 1 according to the invention is shown, which in this embodiment comprises four compression stages A, B, C, D.

[0029] Each compression stage A, B, C, D comprises a piston 3A, 3B, 3C, 3D located in a compressor cylinder 2A, 2B, 2C, 2D so that it can move longitudinally. The pistons 3A-3D are drivingly connected with the common drive train 4 to jointly drive the pistons 3A-3D.

[0030] In the embodiment shown, the drive train 4 consists of a crank or eccentric shaft 6 driven by a drive motor 5, such as an electric motor or an internal combustion engine, wherein the pistons 3A-3D are each mechanically connected to the crankshaft 6 by connecting rods 7A-7D. Fittings 8A-8D can be introduced, wherein the connecting rods 7A-7D are hingedly connected to the crank or eccentric shaft 6 .

[0031] According to the invention, each piston 3A-3D is connected in the compressor cylinder 2A-2D by a liquid column 9A-9D consisting of an incompre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com