A function calibration system and function calibration method for diesel engine electronic control data

A control function and electronic control technology, applied in electrical control, engine control, mechanical equipment, etc., can solve problems such as complex logic operations, large data, and control problems that cannot be checked out, and achieve accurate calculation results and the effect of breaking away from dependencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

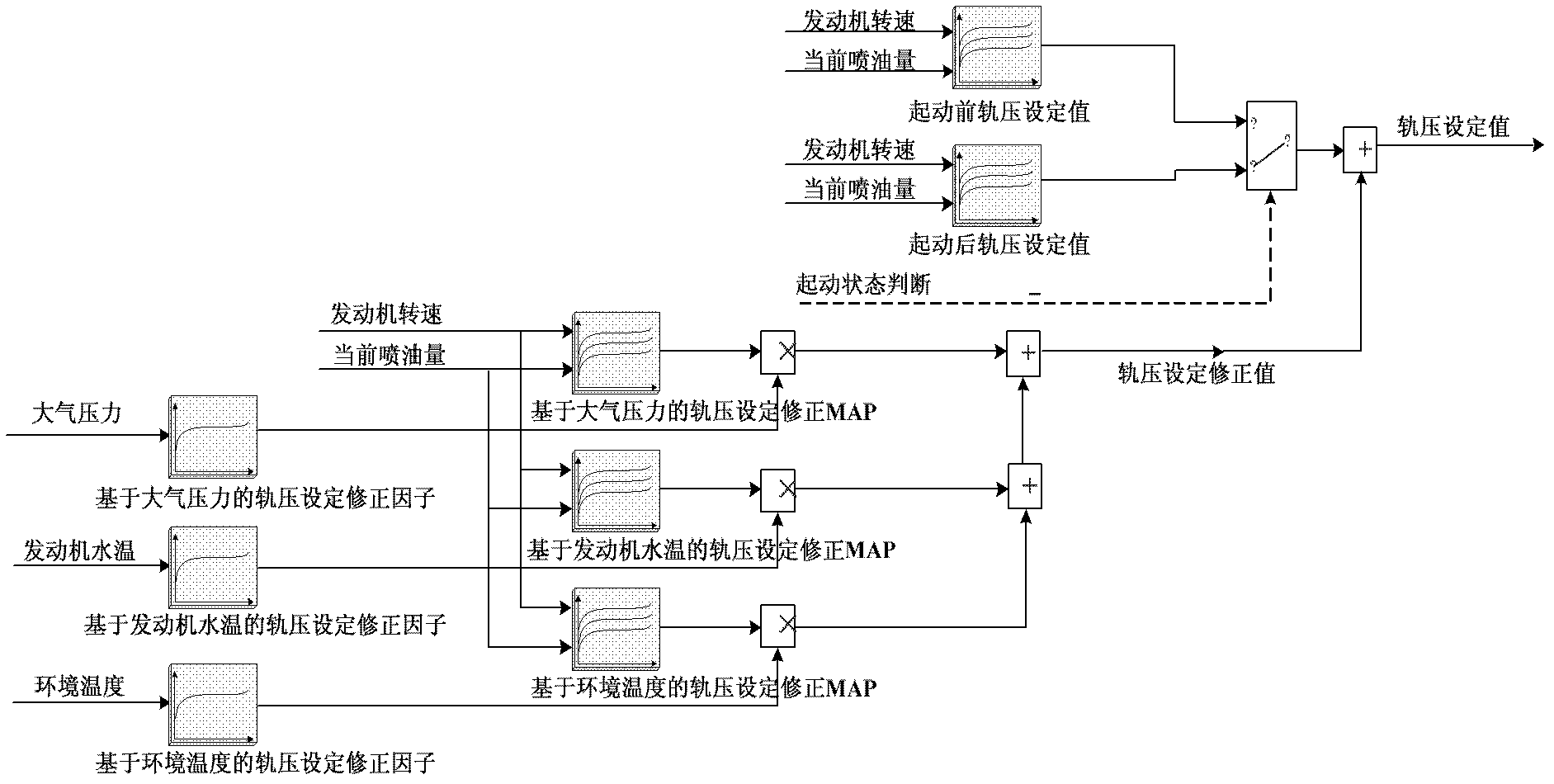

[0033] The present invention is a diesel engine electric control data function proofreading system and a function proofreading method, which is used for global proofreading of the diesel engine electric control calibration data in terms of function realization, and the proofreading result is comprehensive and correct, which solves the one-sidedness of subjective selectivity of experienced engineers question.

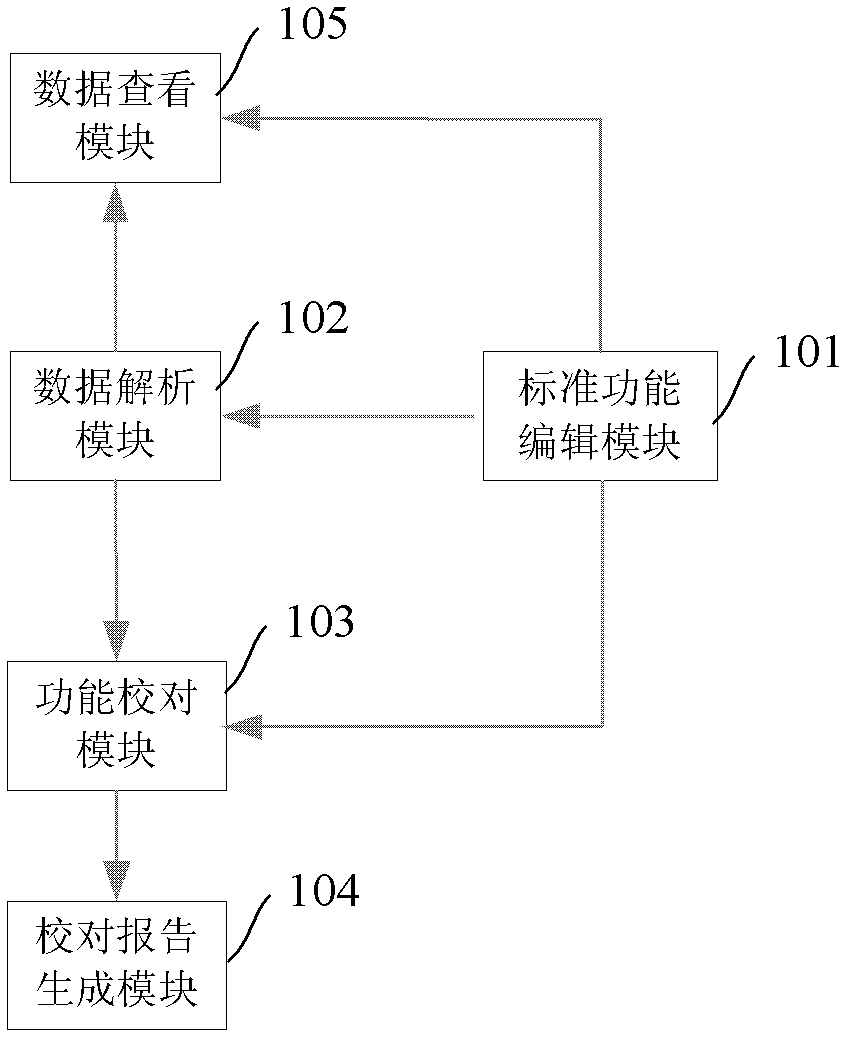

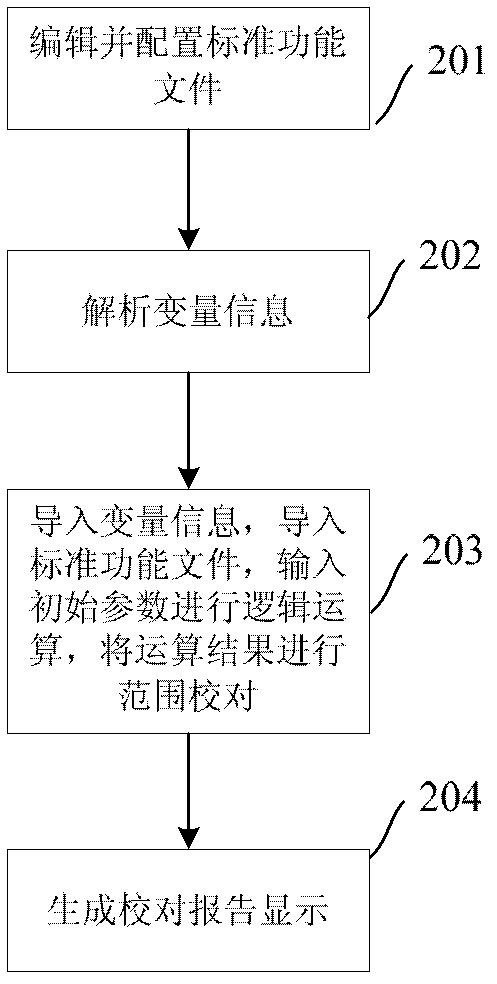

[0034] The system provided by the present invention includes a data analysis module, a standard function editing module, a function proofreading module and a proofreading report generation module. The standard function editing module creates and edits a standard function file and stores it. The proofreading variable information in the calibration data is stored, the function proofreading module imports the standard function file from the standard function editing module, the proofreading variable information imported from the data analysis module uses the standard functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com