Method for repairing and constructing thin overlay of cement concrete road pavement

A technology for cement concrete and concrete pavement, applied in road repair, roads, roads, etc., can solve the problems of high maintenance cost, falling off of the cover layer, and many labors, etc., to increase the bonding area, improve the bonding strength, high The effect of adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The highway cement concrete pavement thin-layer overlay construction method of the present embodiment comprises the following steps:

[0028] 1) Mechanically cut V-shaped grooves parallel to each other on the old cement concrete pavement; control the depth of the V-shaped grooves at about 0.5cm, and the distance between adjacent V-shaped grooves at about 0.5cm;

[0029] 2) Clean up the dirt left on the surface and the place to be shed after mechanically cutting the V-shaped groove with water and a wire brush;

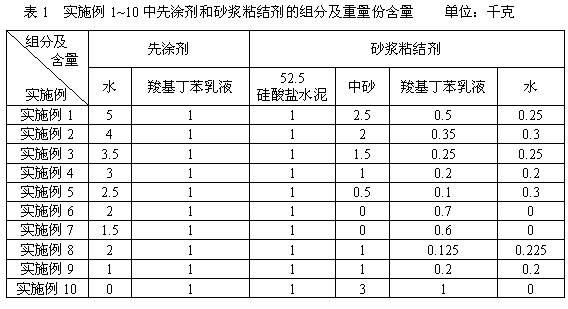

[0030] 3) After step 1) and step 2), the old cement concrete pavement is evenly painted with the first coating agent twice (it can also be sprayed, the effect is basically the same), forming a first coating; the first coating agent Components and parts by weight are as shown in the corresponding items in Table 1. The preparation method of the first coating agent is conventional mixing and stirring preparation, and the first coating agent can be prepared on site; ...

Embodiment 2

[0034] The difference between the road cement concrete pavement thin-layer overlay repair construction method of this embodiment and embodiment 1 is that: in step 1), the depth of the V-shaped groove is controlled at about 1 cm, and the distance between adjacent V-shaped grooves is 1 cm. about 1cm; in step 3), the components and parts by weight of the pre-coating agent are shown in the corresponding items in Table 1; in step 4), the components and parts by weight of the mortar binder are shown in Table 1 As shown in the corresponding item, control the thickness of the mortar bonding layer at about 1 mm.

Embodiment 3

[0036] The difference between the repair construction method of the road cement concrete pavement thin layer overlay of this embodiment and embodiment 1 is that: in step 1), the depth of the V-shaped groove is controlled at about 2 cm, and the distance between adjacent V-shaped grooves is 2 cm. about 2cm; in step 3), the components and parts by weight of the pre-coating agent are shown in the corresponding items in Table 1; in step 4), the components and parts by weight of the mortar binder are shown in Table 1 As shown in the corresponding item, control the thickness of the mortar bonding layer at about 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com