Dyeing method of white bamboo charcoal terylene fiber

A dyeing method, polyester fiber technology, applied in dyeing method, fiber treatment, dry-cleaning fiber products, etc., can solve the problems of bamboo charcoal's health care function, poor color fastness, low dyeing rate, etc., to increase dyeing rate and color Fastness and soft touch performance, effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

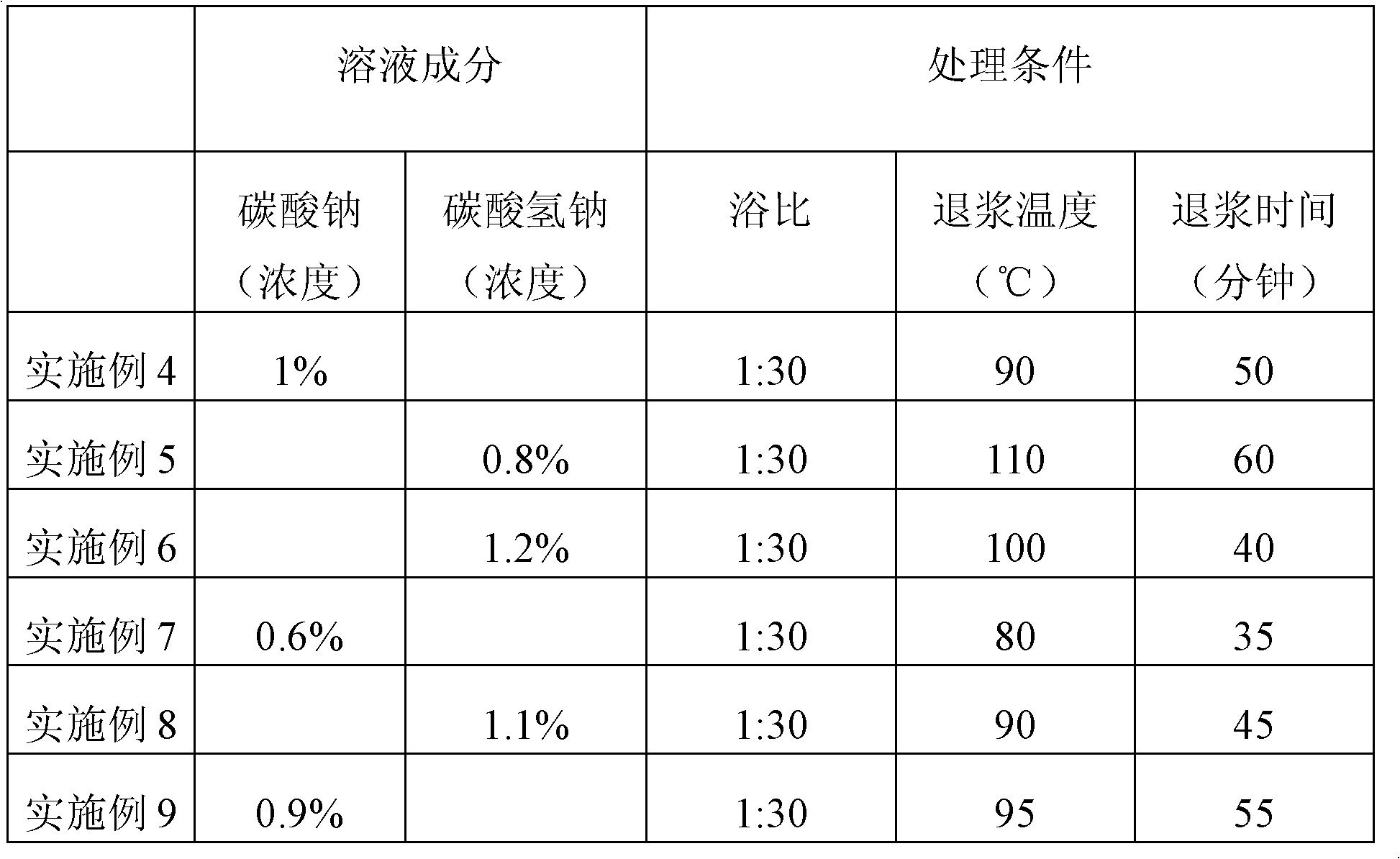

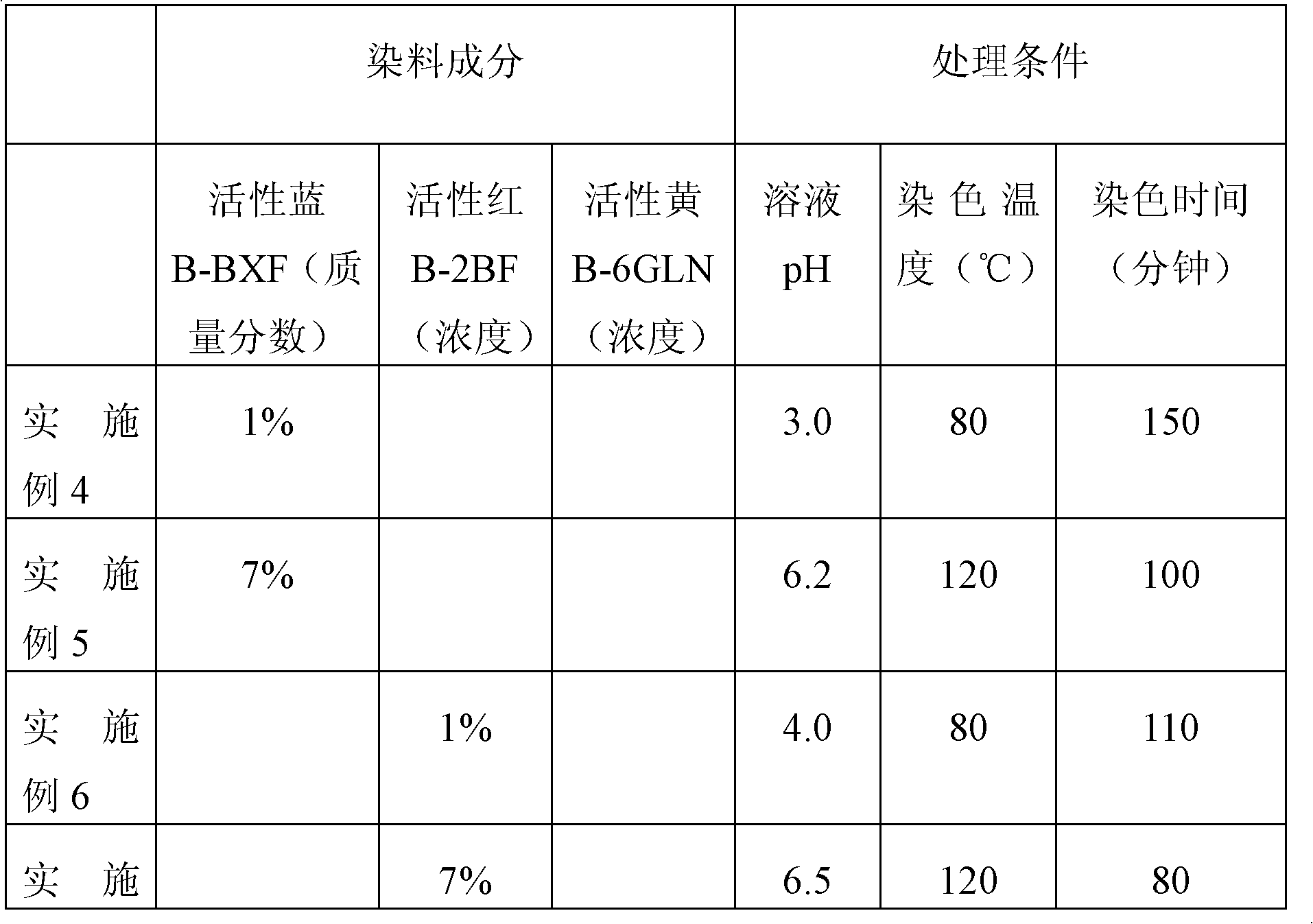

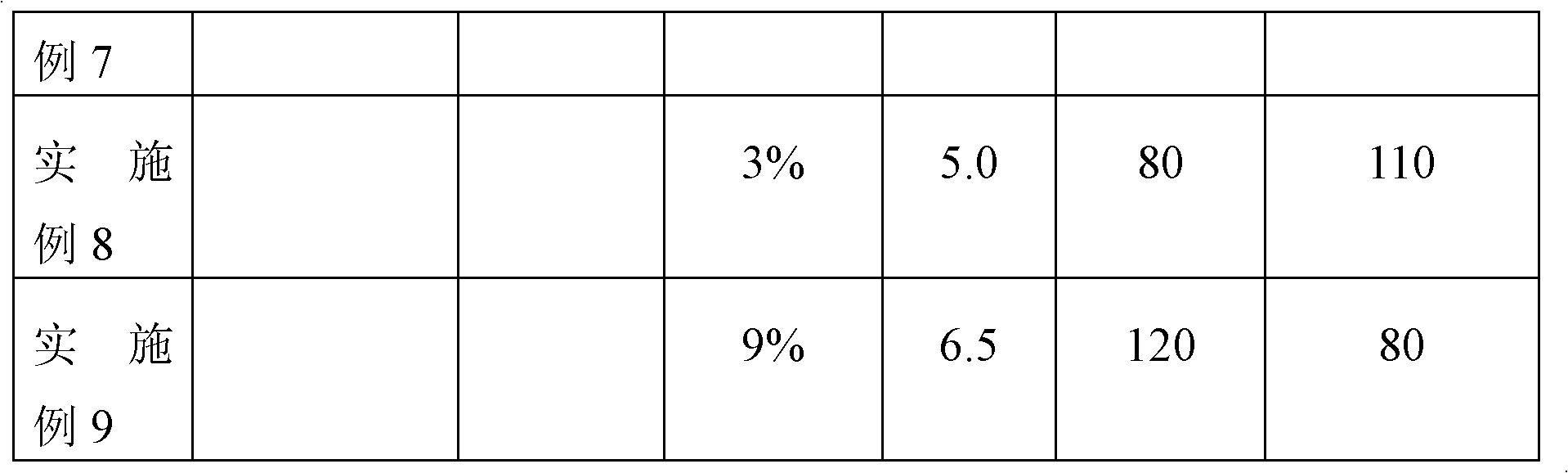

Examples

Embodiment 1

[0025] A white bamboo charcoal polyester fiber dyeing process includes the following steps: desizing→dyeing→alkali weight reduction→reduction cleaning→taking out and drying.

[0026] In the desizing process, it is made into a sodium carbonate solution with a concentration of 0.8% to obtain a desizing solution; in order to obtain a better desizing effect, add detergent 209 to a concentration of 0.5%, certainly those skilled in the art can clearly know that the net Lotion is not necessary here; adjust the bath ratio to be 1:30, and at a desizing temperature of 80°C, use the desizing solution to process the white bamboo charcoal polyester fiber or fabric for 30 minutes, take out the fiber or fabric, and put it into Dye in the dyeing vat containing the prepared dyeing solution.

[0027] Those skilled in the art should understand that the "concentration" mentioned above and below refers to mass concentration for solids and volume concentration for liquids.

[0028] Described dyein...

Embodiment 2

[0033] In the desizing process, it is made into a sodium carbonate solution with a concentration of 0.5% to obtain a desizing solution. In order to obtain a better desizing effect, add detergent 207 to a concentration of 0.8%. Of course, those skilled in the art can clearly know that the net Lotion is not necessary here; adjust the bath ratio to be 1:30, and at a desizing temperature of 100°C, use the desizing solution to process the white bamboo charcoal polyester fiber or fabric for 60 minutes, take out the fiber or fabric, and put it into Dye in the dyeing vat containing the prepared dyeing solution.

[0034] Described dyeing solution is the aqueous solution that contains the active red B-2BF dyestuff of concentration 5%, the sodium sulfate of concentration 3%, the ammonium sulfate of concentration 0.1%, the dispersant NNO of concentration 0.1%; Adjust the pH value of dyeing solution to be 5.5, Dyeing was carried out at a temperature of 80° C. for 100 minutes.

[0035] The...

Embodiment 3

[0038] In the desizing process, a sodium bicarbonate solution with a concentration of 1% is prepared to obtain a desizing solution, and detergent 209 is added to a concentration of 1.5%; the bath ratio is adjusted to 1:30, and the desizing temperature is 90° C. After the white bamboo charcoal polyester fiber or fiber fabric was treated with the desizing solution for 40 minutes, the fiber or fiber fabric was taken out and put into a dyeing vat equipped with a prepared dyeing solution for dyeing.

[0039] Described dyeing solution is the aqueous solution that contains the reactive yellow B-6GLN dyestuff of concentration 7%, the sodium sulfate of concentration 5%, the ammonium sulfate of concentration 0.3%, the dispersant NNO of concentration 0.2%; Adjust the pH value of dyeing solution to be 6.0, Dyeing was carried out at a temperature of 120° C. for 100 minutes.

[0040] Put the dyed fiber or fabric into the alkali weight reduction tank filled with the prepared alkali weight re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com