Ceftriaxone sodium compound and preparation method thereof

A technology of ceftriaxone sodium and ceftriaxone, which is applied in the field of medicine, can solve problems such as operator injury, increased production costs, and environmental pollution, and achieve the effects of improved product quality, simple operation, and reduced incidence of allergic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

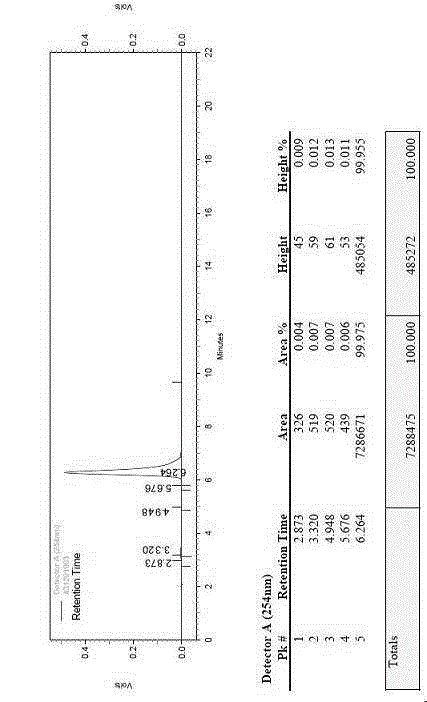

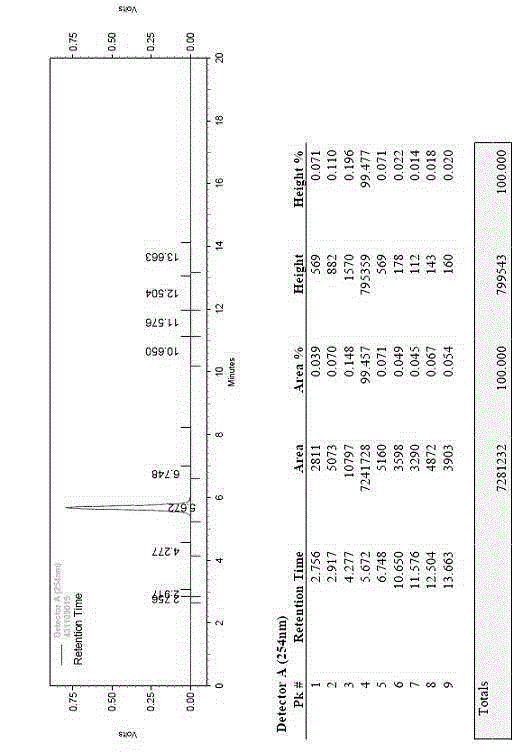

Image

Examples

Embodiment 1

[0044] Take 86g of crude ceftriaxone sodium, add 129mL of purified water and stir until the solids are completely dissolved, filter, add potassium chloride to the filtrate, stir, stop adding when crystals are precipitated, add a total of 86g of potassium chloride, and grow crystals at 25°C 30 minutes, suction filtration, beating and washing with 20% acetone water 250mL, then washing with acetone 200mL, draining, and vacuum drying to obtain 62.1g of ceftriaxone sodium composition, yield 72.2%. The obtained product was tested according to the requirements of the Chinese Pharmacopoeia 2010 edition, and the test results are shown in Table 1.

Embodiment 2

[0046] Get 92g of ceftriaxone sodium crude product, add 645mL of water for injection and stir until the solids are completely dissolved, filter, add ammonium sulfate to the filtrate, stir, when crystals are precipitated, stop adding, add 13.1g of ammonium sulfate in total, and grow crystals at 15°C After 45 minutes, filter with suction, first wash with 250 mL of 20% acetone water, wash with 200 mL of acetone, drain, and dry in vacuum to obtain 73.2 g of ceftriaxone sodium composition, with a yield of 79.6%. The obtained product was tested according to the requirements of the Chinese Pharmacopoeia 2010 edition, and the test results are shown in Table 1.

Embodiment 3

[0048] Take 75g of crude ceftriaxone sodium, add 225mL of purified water and stir until the solids are completely dissolved, add potassium nitrate, stir, stop adding when crystals are precipitated, add a total of 12.5g of potassium nitrate, grow crystals at 5°C for 5 minutes, and filter with suction , first beating and washing with 20% acetone water 250mL, then washing with acetone 200mL, draining, and vacuum drying to obtain 60.9g of ceftriaxone sodium composition, with a yield of 81.2%. The obtained product was tested according to the requirements of the Chinese Pharmacopoeia 2010 edition, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com