Feed mechanism of valve bag capping machine

A technology of feeding mechanism and sealing machine, which is applied in the direction of packaging, etc., can solve the problems of complex design, material feeding cannot be in place at one time, and easy folding of valve bag materials, etc., and achieve the effect of reasonable design, uniform and stable feeding process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

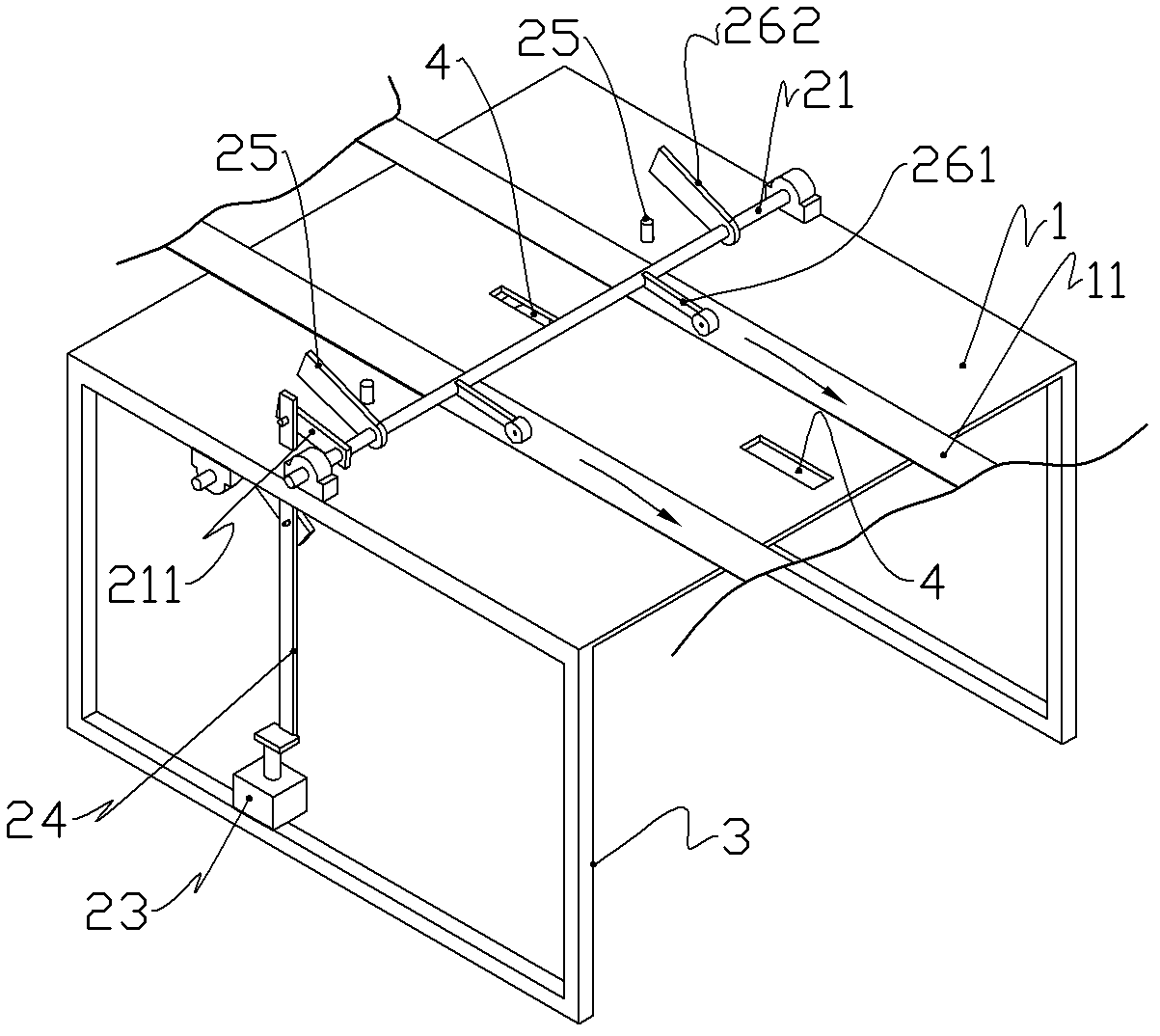

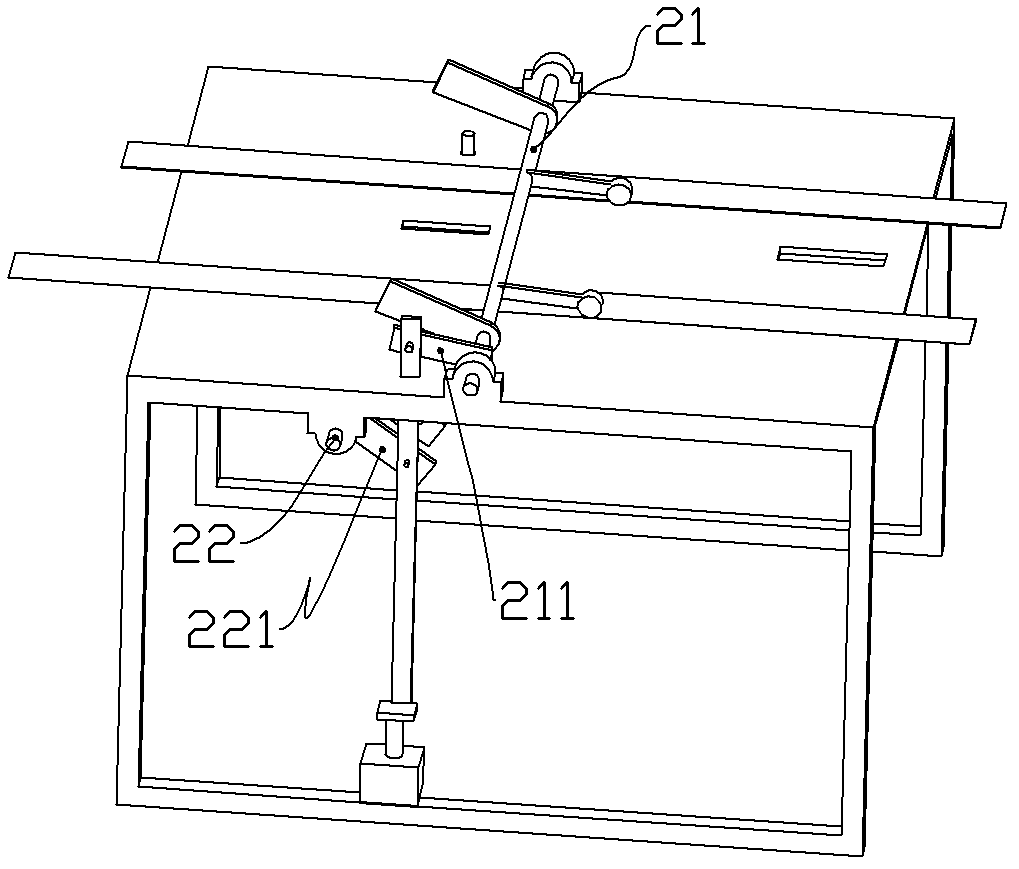

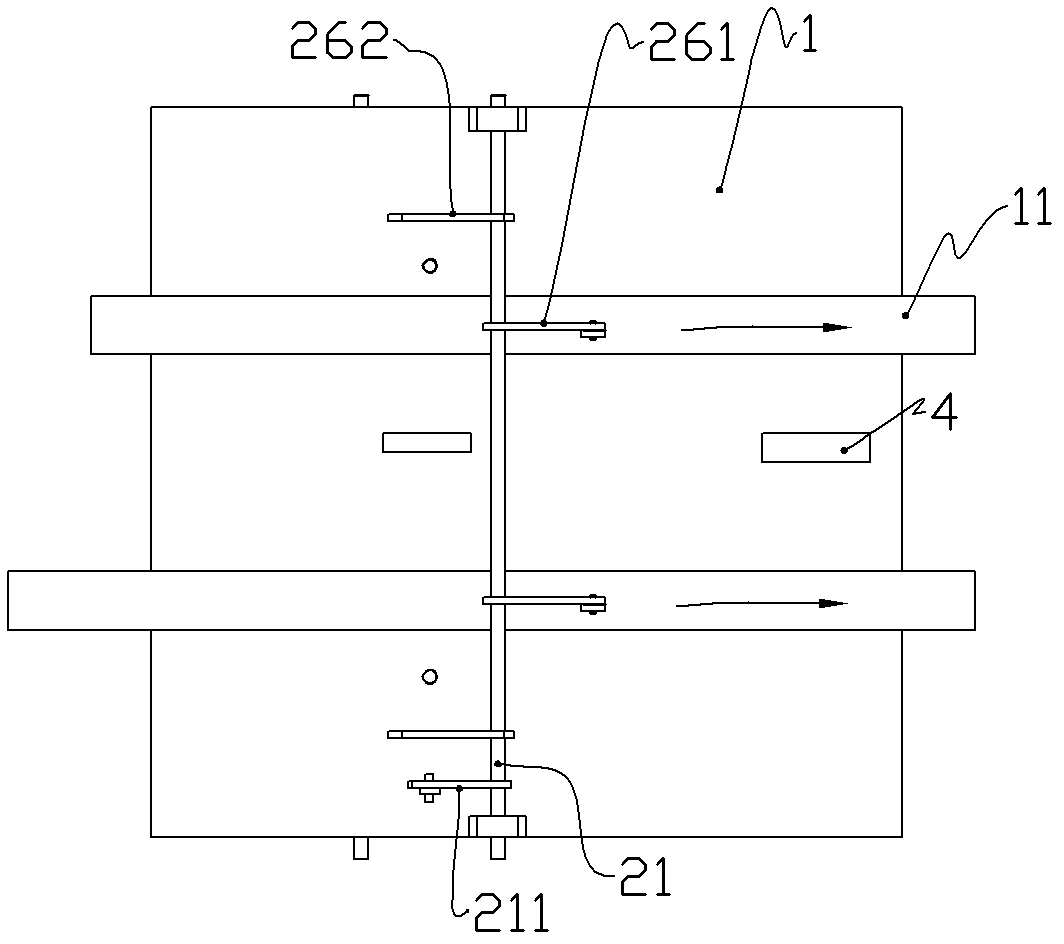

[0013] Valve bag sealing machine, including frame 3 and the feeding part, sealing part, and sealing bottom installed on the frame in sequence. The feeding part requires uniform feeding, and only one valve bag blank should be fed at a time. A single feeding should not overlap or be many , Do not leak.

[0014] Emphasis is on the improvement of feeding section, and feeding section comprises stacking platform 1, belt conveyor 11 and feeding mechanism, and belt conveyor is made up of front and rear rotating shaft, conveyer belt and drive motor, is identical with existing belt conveyor.

[0015] Such as Figure 1 to Figure 5 As shown, the feeding mechanism is an auxiliary device of the valve bag sealing machine. It includes a stacking platform 1 and a feeding mechanism. The stacking platform 1 is a thin steel plate. The stacking platform 1 is welded on the upper side of the frame 3 to form a working table, and a sensor installation hole 4 is opened on the stacking platform. It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com