Soft bag automatic filling equipment for transfusion and method for filling transfusion soft bag

A technology for filling equipment and infusion soft bags, which is applied in the field of semi-automatic infusion soft bag filling devices. It can solve the problems of opening and inserting openings of soft infusion bags, difficulty in loading bags, and wiping and hanging, so as to improve comfort and cost. Inexpensive, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

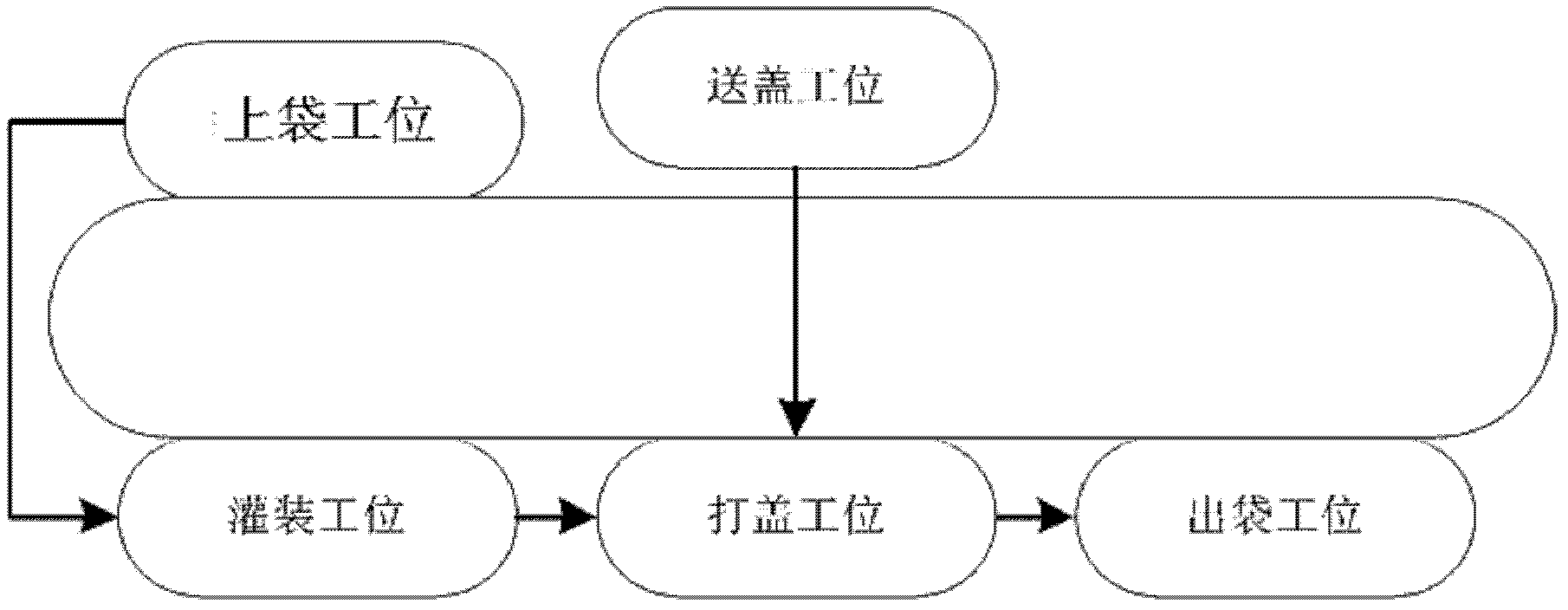

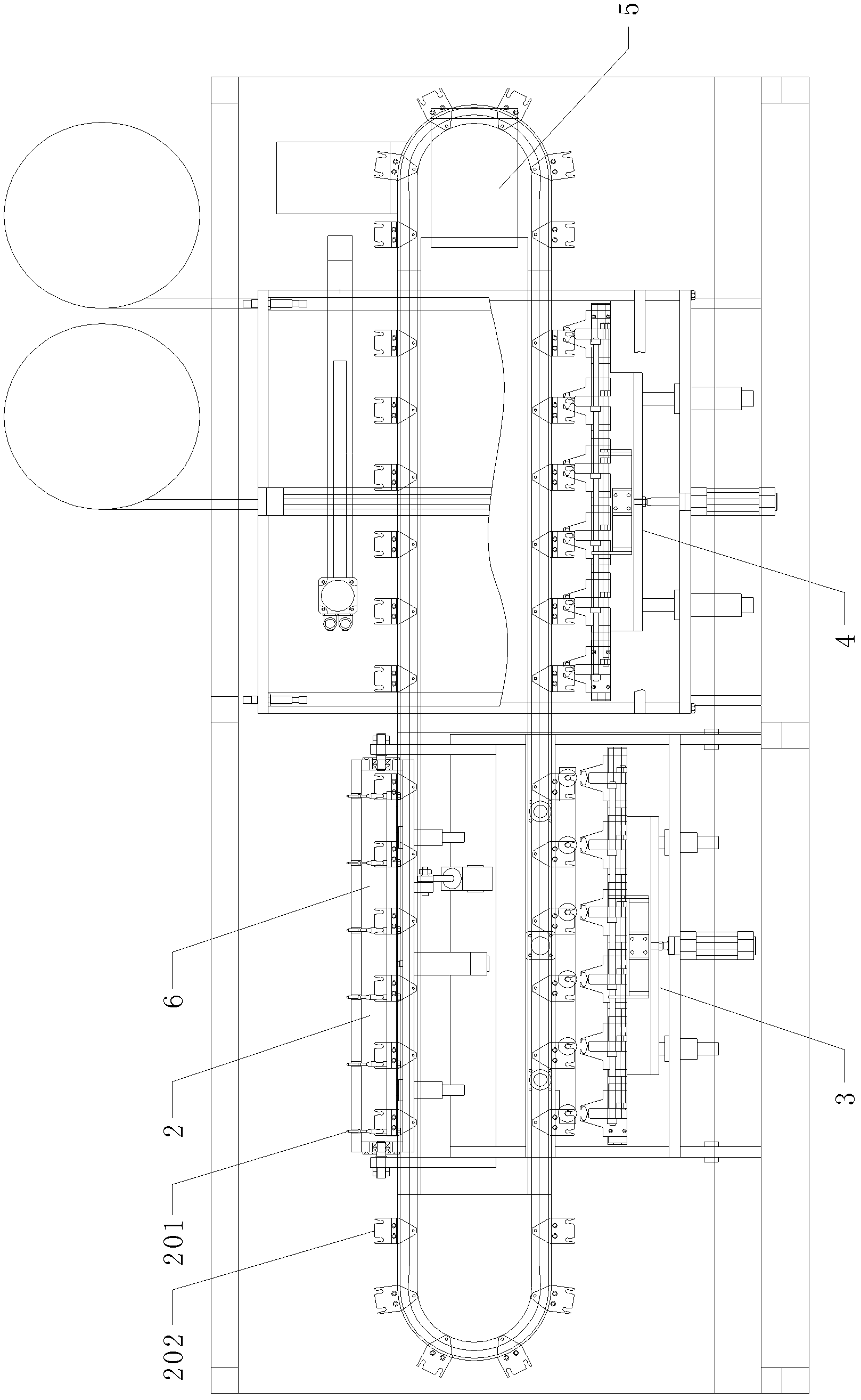

[0096] see Figure 1 to Figure 5 , the semi-automatic soft bag filling equipment for infusion in this embodiment includes a frame 1 and a PLC controller, and the frame 1 is provided with a bag loading station 2 and a bag transmission mechanism 202;

[0097] According to the process requirements of infusion soft bag filling, several operating stations are arranged in sequence behind the bag loading station 2, such as filling station 3, capping station 4, bag discharging station 5, etc.;

[0098] The bag transmission mechanism 202 is roughly in the shape of a racetrack and laid in a horizontal direction. The bag transmission mechanism 202 can transfer and transport the infusion soft bag between various operating stations. At least one clamping manipulator 202a is arranged on the bag transmission mechanism 202, and the clamping manipulator 202a can be used to clamp the filling tube of the infusion soft bag and prevent it from falling off during transportation.

[0099] An inser...

Embodiment 2

[0107] In this embodiment, the main difference from Embodiment 1 is that the bag turning mechanism 203 used to drive the insertion nozzle 201 to rotate along the vertical plane includes a turning shaft, and the turning shaft is placed outside the frame 1. The rotation axis is located in the horizontal direction and is connected to one end of the socket nozzle 201. The socket nozzle 201 and the turning axis rotate synchronously in the vertical plane. In this way, the socket nozzle 201 rotates around the turning axis in the vertical plane.

[0108] Please refer to Embodiment 1 for other structures.

Embodiment 3

[0110] see Figure 4 and Figure 5 , in this embodiment, the main difference from Embodiment 1 is that the bag turning mechanism 203 for driving the socket nozzle 201 to rotate along the vertical plane includes a first cylinder 203a, and one end of the first cylinder 203a is connected to the frame 1 Hinged, the other end of the first cylinder 203a is hinged with one end of the socket 201;

[0111] The middle part of the socket nozzle 201 is hinged with the frame 1, and the socket nozzle 201 and the frame 1 are hinged along the horizontal axis, and the other end of the socket nozzle 201 is driven by the first cylinder 203a, and the hinge is used as the rotation axis Rotate in a vertical plane.

[0112] At this time, the socket mouth 201 is used to connect one end of the infusion soft bag, and the end connected with the socket mouth 201 to the first cylinder 203a is respectively located at the two ends of the hinge between the socket mouth 201 and the frame 1, and the first cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com