Manufacture method of superfine intaglio roller

A technology of a gravure plate roller and a manufacturing method, which is applied in the directions of printing plate preparation and printing, can solve the problems of small cell volume, low ink content in printed products, insufficient color saturation, etc., and achieves high ink content in patterns. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

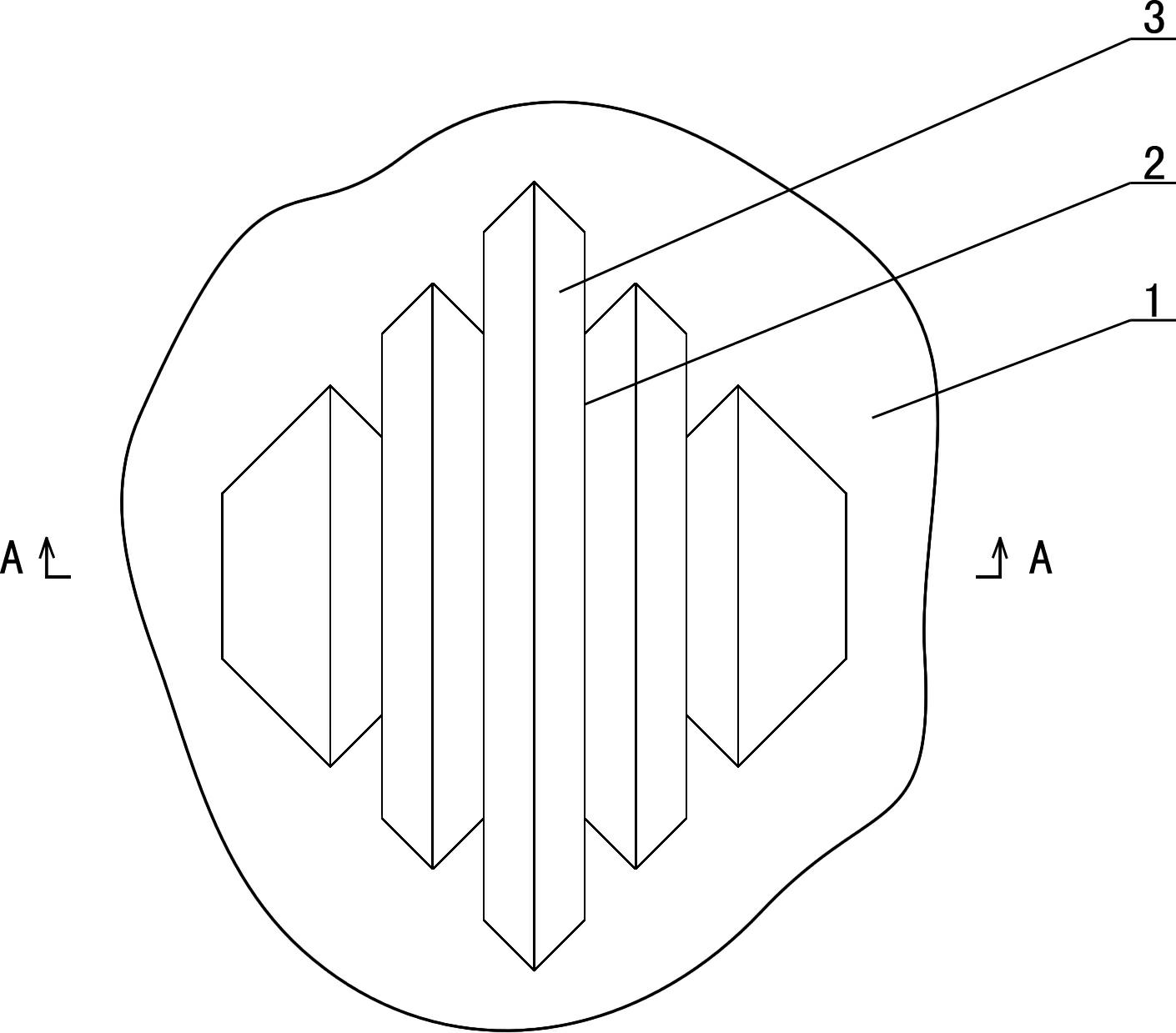

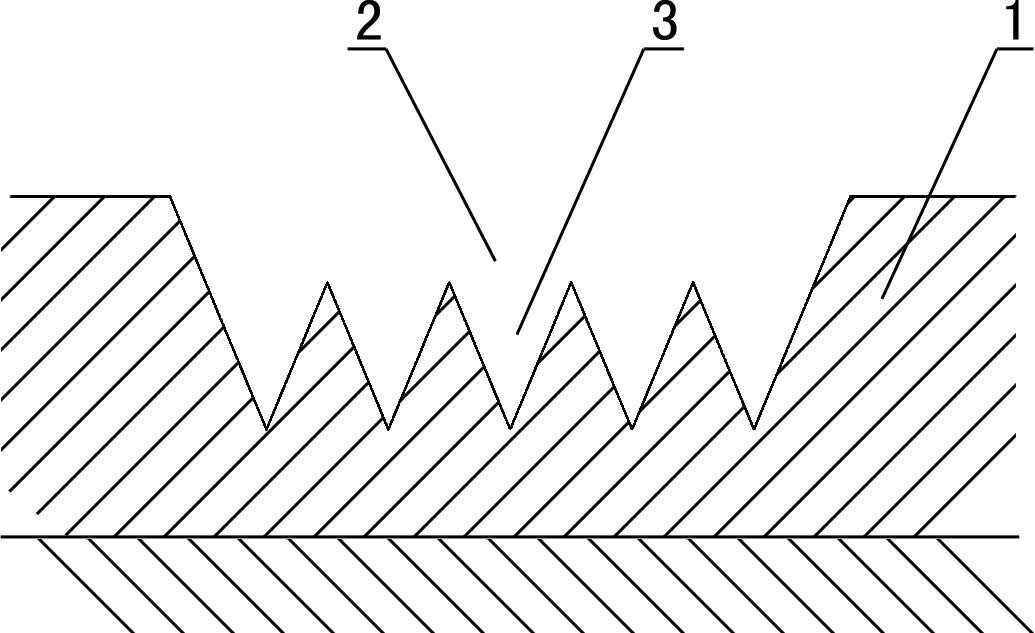

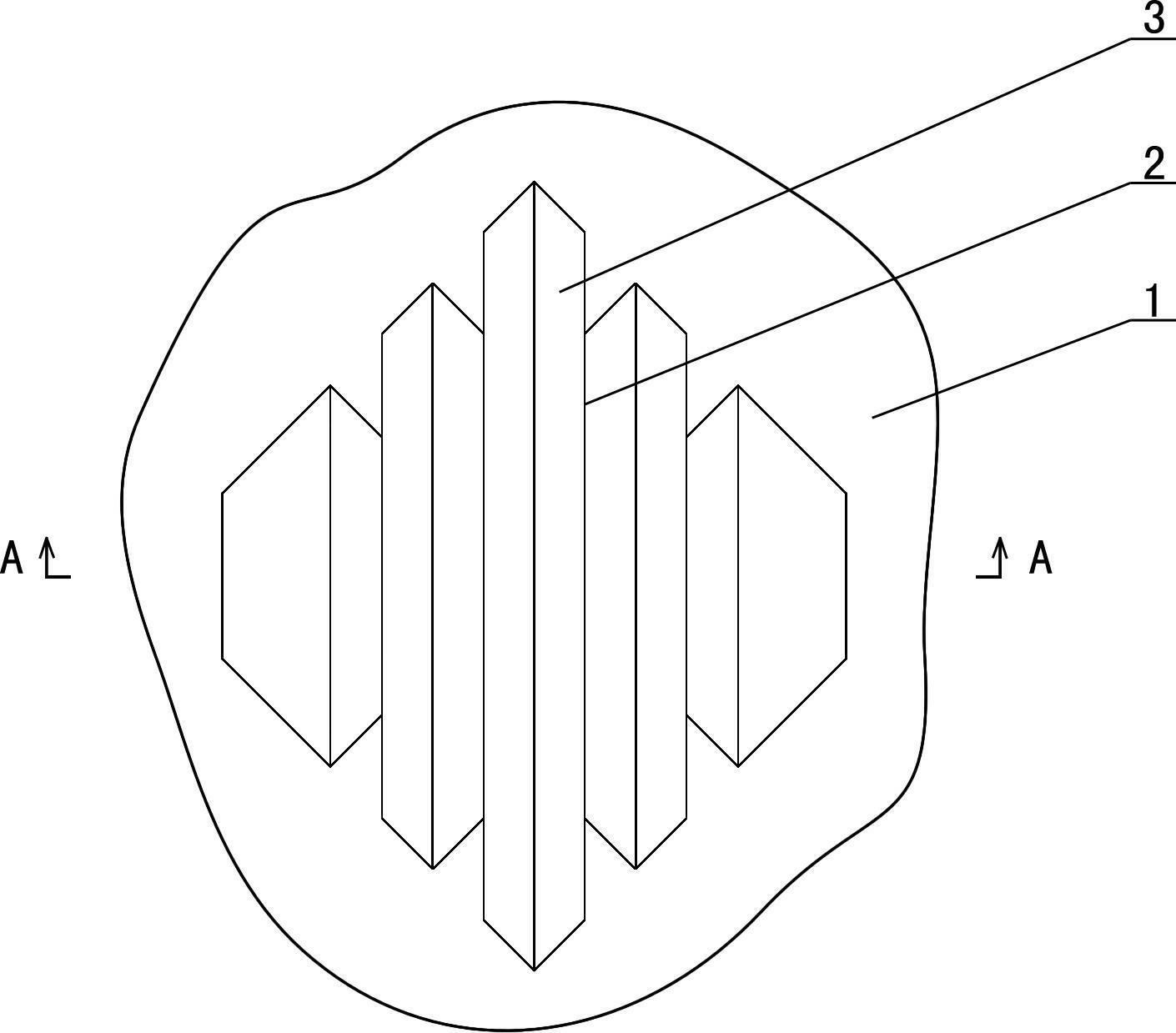

[0014] In the present embodiment, the manufacturing method of ultra-fine gravure plate roll comprises the following steps:

[0015] (1) making a version roller body, the cylindrical surface of the prepared version roller body has a layer of copper layer 1;

[0016] In this embodiment, a cylindrical steel pipe is used as the plate roll base 4, and then a layer of copper layer 1 with a uniform thickness is plated on the cylindrical surface of the plate roll base 4 to obtain a plate roll body, wherein the copper layer 1 is the working surface of electronic engraving;

[0017] (2) Make a subpoena file according to the design pattern, and send the subpoena file to the electronic engraving machine;

[0018] (3) The electronic engraving machine forms an engraving control signal according to the subpoena document, drives the movement of the engraving knife and the plate roller body, the engraving knife engraves on the copper layer 1, and the engraving knife forms an engraving groove 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com