Method for assembling heavy core-pulling mechanism of large injection mould

A technology for injection molds and core-pulling mechanisms, applied in the field of assembly of heavy-duty core-pulling mechanisms, can solve the problems of difficult assembly, labor and time-consuming, easy to damage core-pulling sliders, etc., and achieve the effect of solving difficult assembly and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

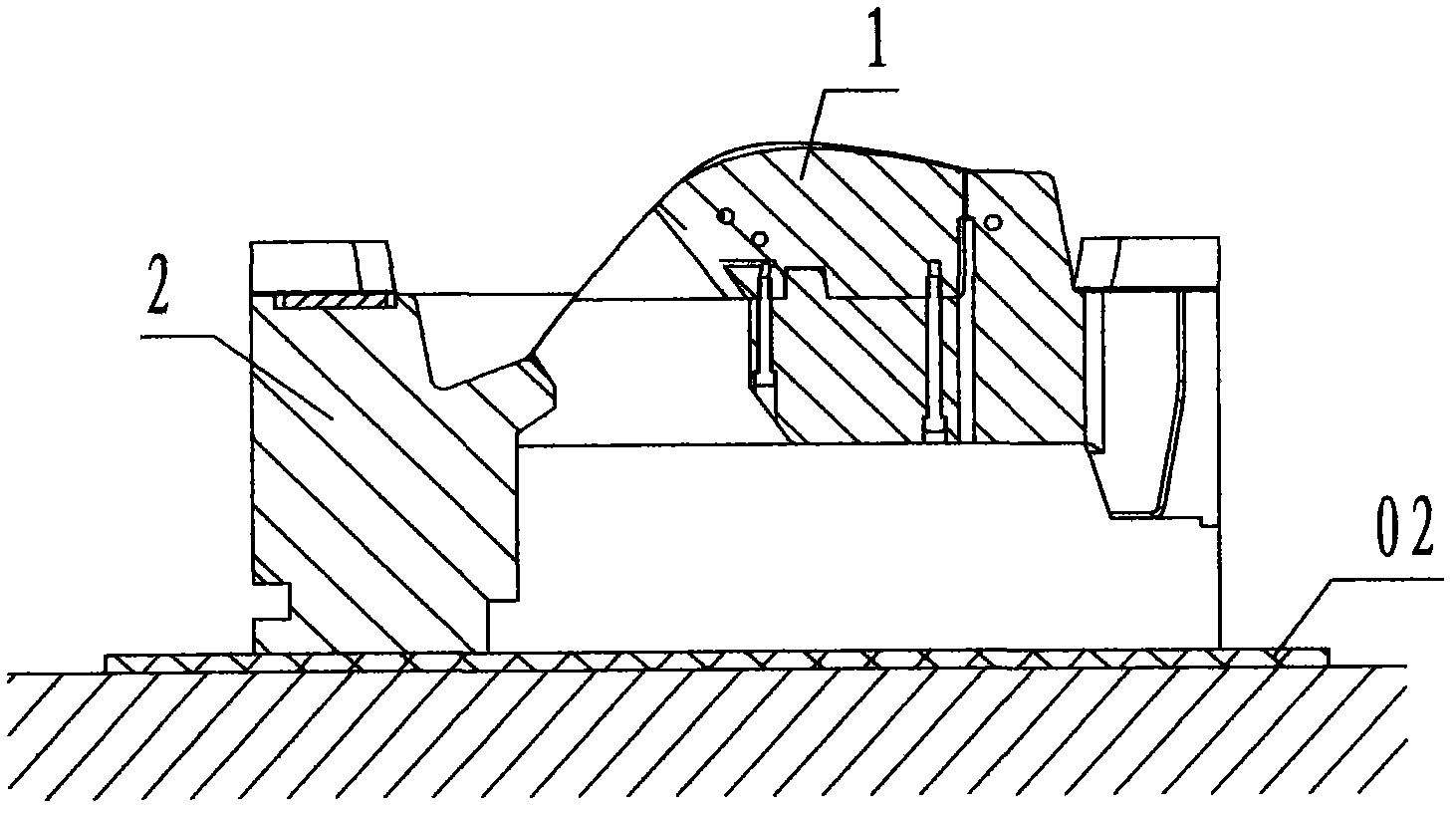

[0024] refer to Figure 1 to Figure 7 , the assembly method of the heavy-duty core-pulling mechanism of a large-scale injection mold of the present invention is an assembly process method, and the assembly process method is: using a crane,

[0025] Step 1, hoisting the moving model core 1 into the moving model carrier plate 2 in the forward direction;

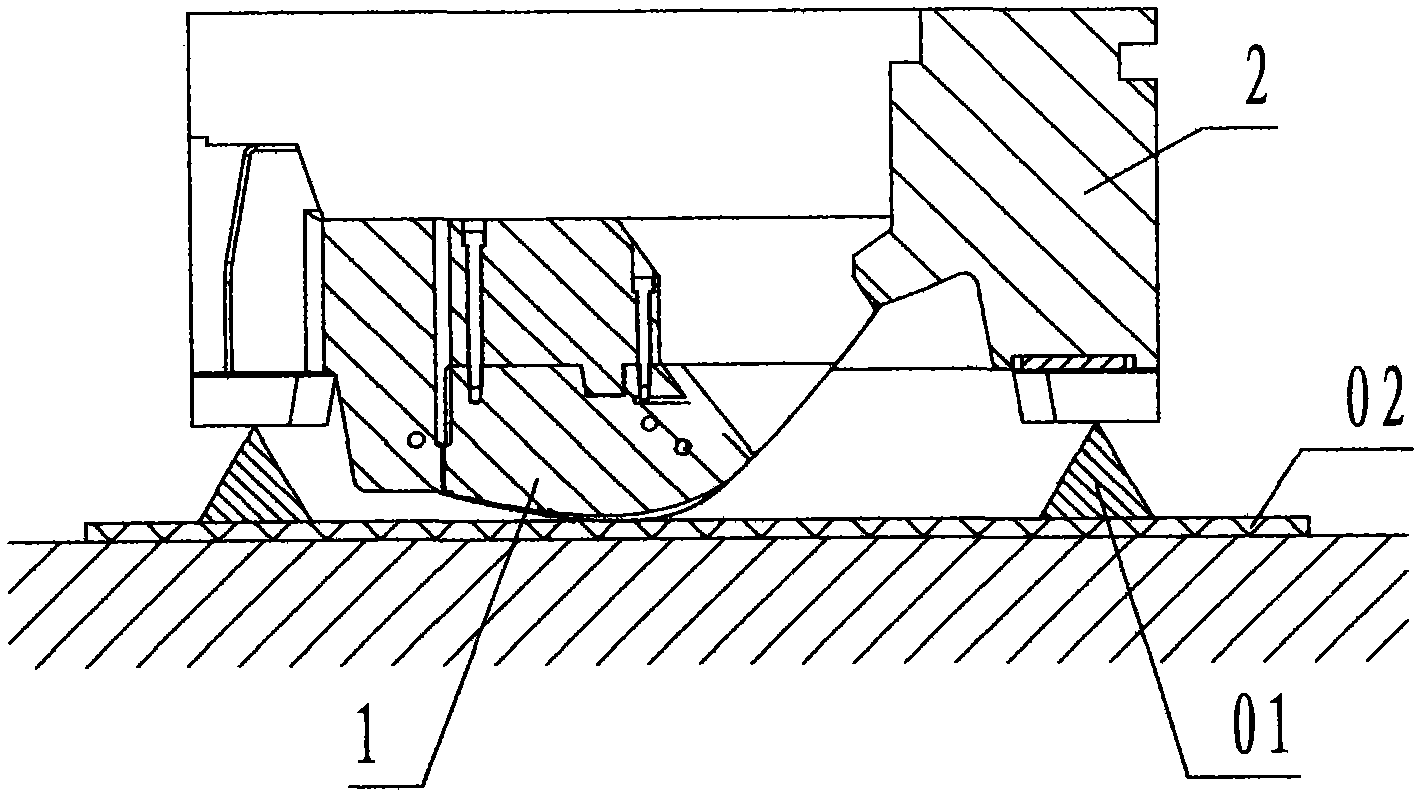

[0026] Step 2, hoist the movable mold carrier plate 2 and the dynamic model core 1 and turn it to 180°, make the bottom surface of the movable mold carrier plate 2 face up and use the support 01 to level the bottom surface of the movable mold carrier plate 2; the support 01 is a jack;

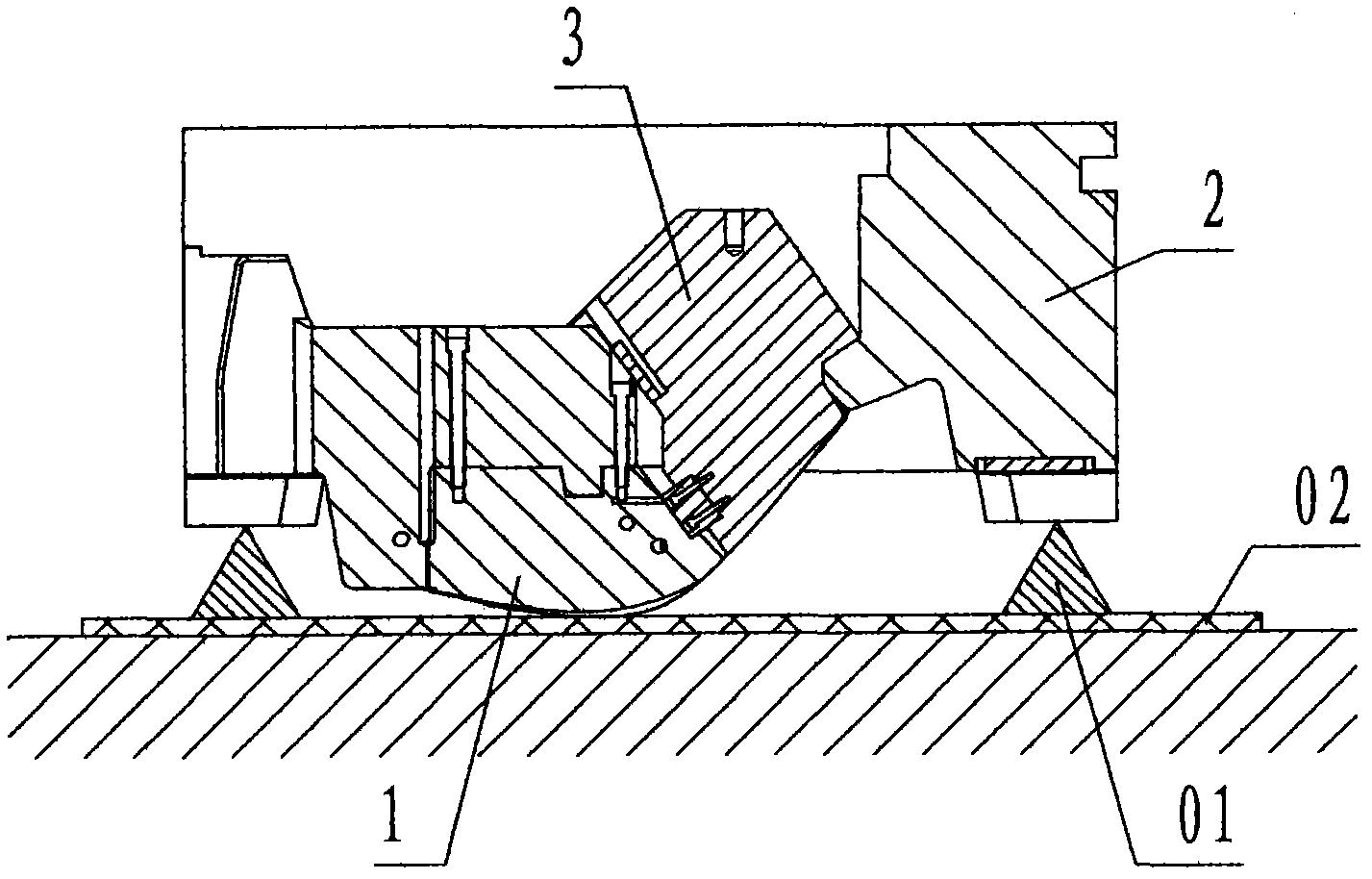

[0027] Step 3: Use a crane to hang the bottom surface of the core-pulling slider 3 through the lifting ring, lift and slide the profile of the core-pulling slider 3 vertically along the corresponding profile of the movable model core 1, and insert it into the movable mold carrier plate 2 and the movable mold core 1 In the core pulling slot;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com