Dispensing method and portable mobile terminal

A mobile terminal and portable technology, applied in the mechanical field, can solve the problems of large distance between the camera hole and the front shell, overall incoordination, and unsightly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

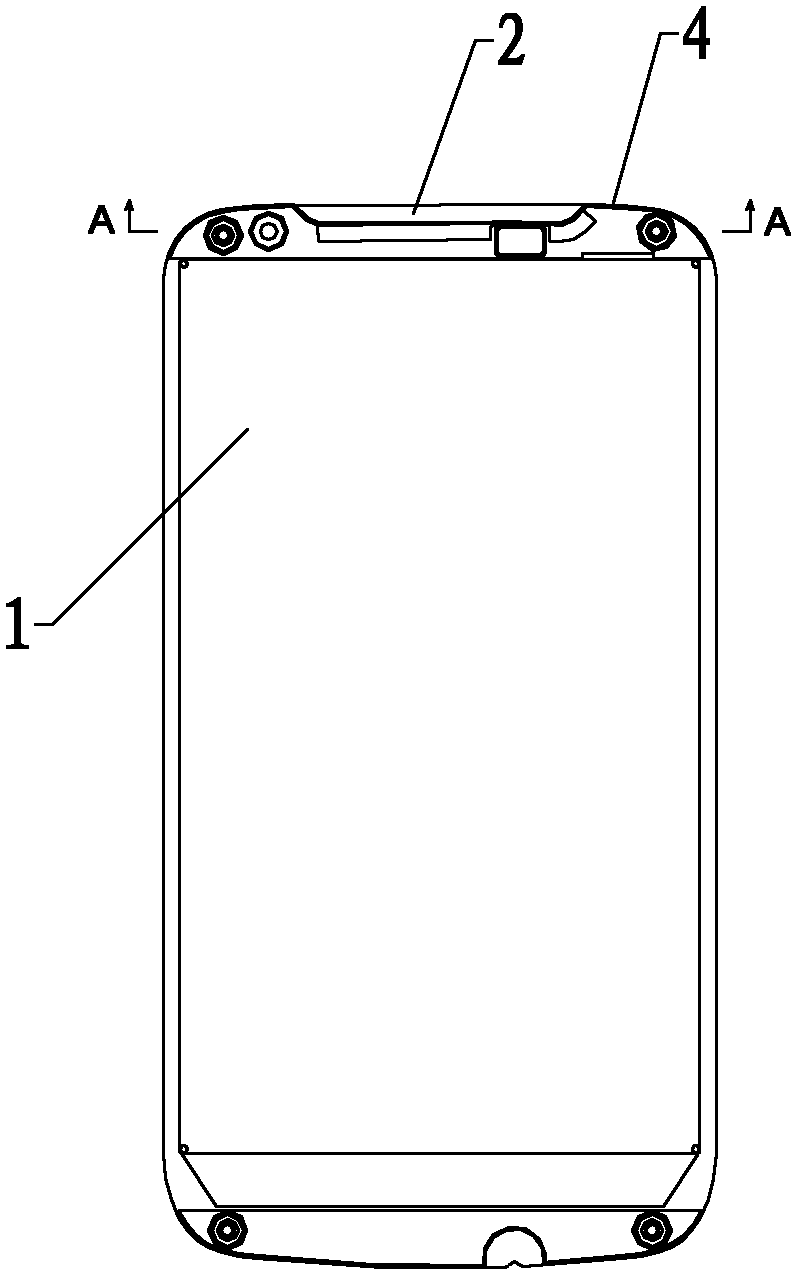

[0025] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the portable mobile terminal includes a touch screen lens 1, an earpiece 2, a bracket 3 and a front shell 4, the bracket 3 is provided with a front camera hole 5, and heat is passed between the bracket 3 around the front camera hole 5 and the touch screen lens 1. The melt glue gun is sealed by dispensing. The distance between the front camera hole 5 and the earpiece 2 and the front shell 4 is less than the width of the glue path 8 on the support 3 plane of the hot melt adhesive. The front camera hole and the earpiece and the front shell The distance between them is 0.2mm; the front camera hole 5 is rounded; the inner wall of the front camera hole 5 is provided with several rings 6; several rings 6 are coaxially arranged; the radius of several rings 6 into an arithmetic progression; the heights of several rings 6 are equal.

[0026] A glue dispensing method comprises the following steps: keeping...

Embodiment 2

[0028] Example 2, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the portable mobile terminal includes a touch screen lens 1, an earpiece 2, a bracket 3 and a front shell 4, the bracket 3 is provided with a front camera hole 5, and heat is passed between the bracket 3 around the front camera hole 5 and the touch screen lens 1. The melt glue gun is sealed by dispensing. The distance between the front camera hole 5 and the earpiece 2 and the front shell 4 is less than the width of the glue path 8 on the support 3 plane of the hot melt adhesive. The front camera hole and the earpiece and the front shell The distance between them is 0.2 mm; the front camera hole 5 is in the shape of a rounded table; the inner wall of the front camera hole 5 is provided with several rings 6 .

[0029] A glue dispensing method comprises the following steps: keeping the pressure of a hot melt glue gun constant, increasing the glue dispensing speed several times, the hot melt glue fo...

Embodiment 3

[0031] Example 3, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the portable mobile terminal includes a touch screen lens 1, an earpiece 2, a bracket 3 and a front shell 4, the bracket 3 is provided with a front camera hole 5, and heat is passed between the bracket 3 around the front camera hole 5 and the touch screen lens 1. The melt glue gun is sealed by dispensing. The distance between the front camera hole 5 and the earpiece 2 and the front shell 4 is less than the width of the glue path 8 on the support 3 plane of the hot melt adhesive. The front camera hole and the earpiece and the front shell The distance between them is 0.2 mm; the front camera hole 5 is in the shape of a rounded table; the inner wall of the front camera hole 5 is provided with several rings 6 .

[0032] A glue dispensing method comprises the following steps: keeping the pressure of a hot melt glue gun constant, increasing the glue dispensing speed several times, the hot melt glue fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com