Process and equipment for rapidly removing iron in slurry

A slurry and fast technology, applied in the field of magnetic separation, can solve the problems of not being able to adapt to the production needs of modern construction ceramics factories, the production efficiency is reduced, and cannot be carried out, so as to achieve the effect of simplifying the structure, improving production efficiency and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

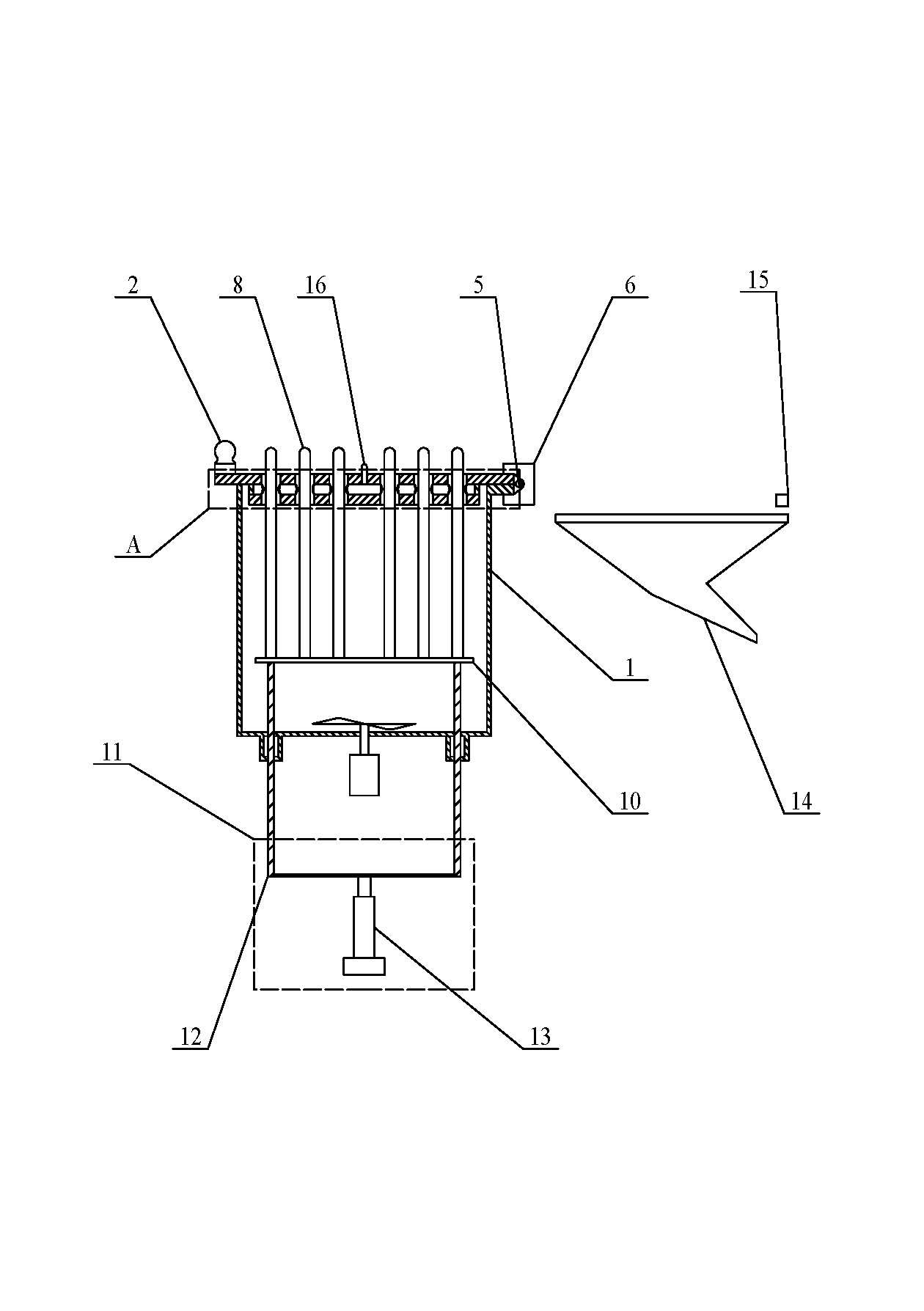

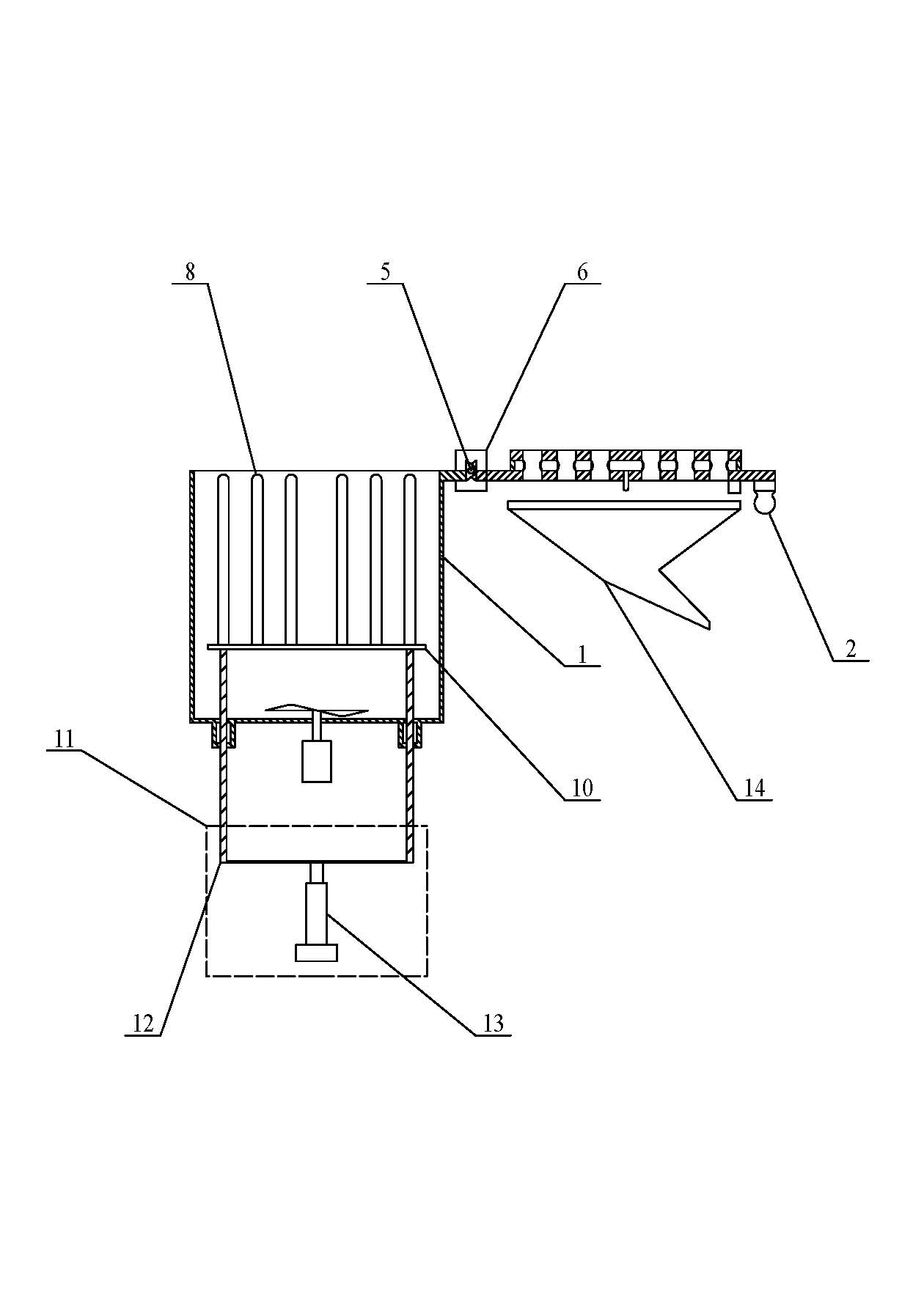

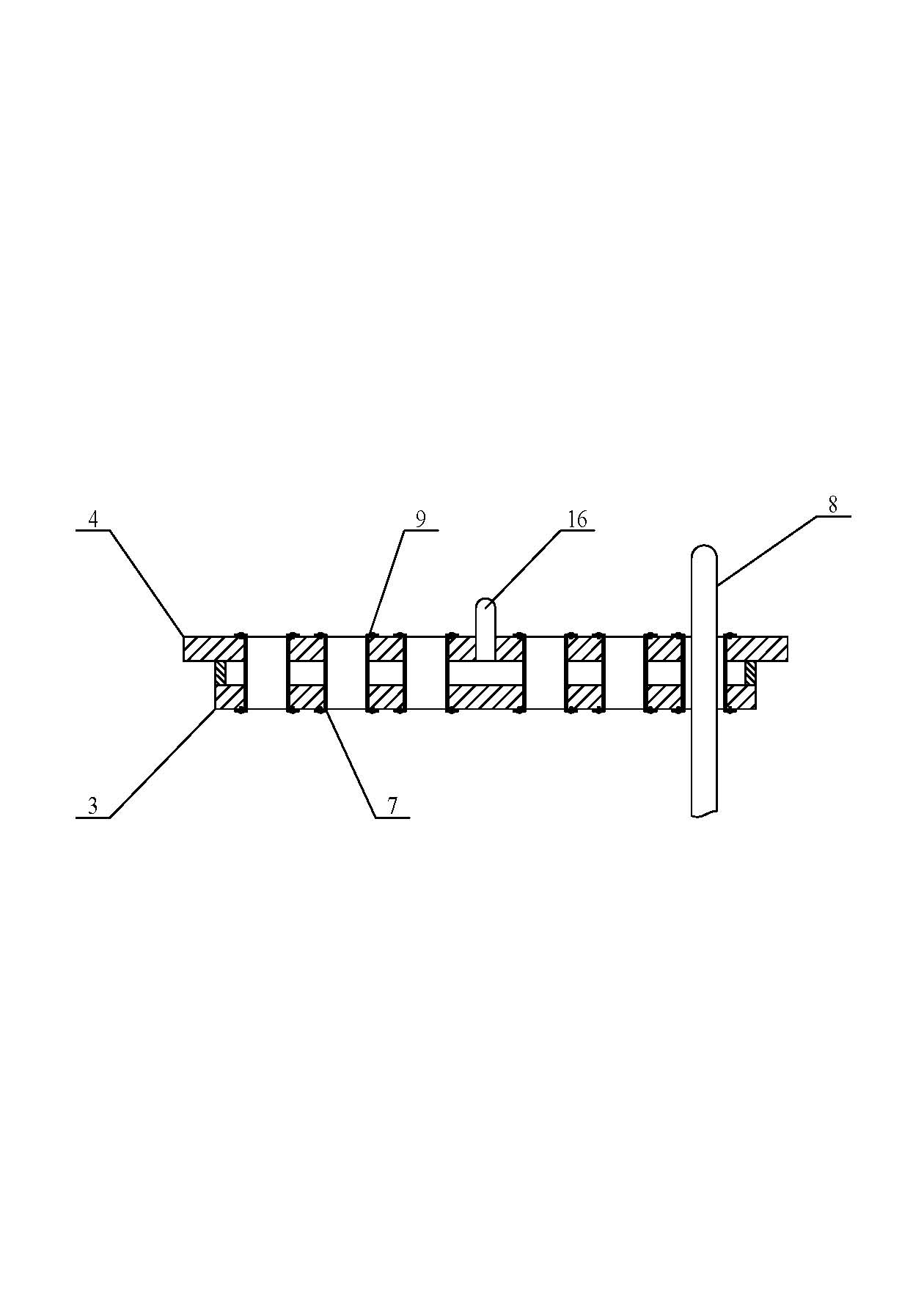

[0030] Such as figure 1 , 2 As shown, a process and equipment for quickly removing iron filings, including a slurry cylinder 1, a vibrating motor 2, a cover plate 3, an iron removal plate 4, a rotating shaft 5, a rotation control device 6, an elastic rubber sleeve 7, and a magnetic bar group 8. Magnetic bar through hole 9, connecting plate 10, lifting device 11, lifting rod 12, hydraulic cylinder 13, iron plate 14, bracket 15 and solenoid valve 16.

[0031] A rotating shaft 5 is fixed on one side of the upper end of the slurry cylinder 1 , the iron removal plate 4 is connected with the rotating shaft 5 , and the rotating shaft 5 is connected with a rotation control device 6 . A magnetic rod group 8 is placed in the slurry cylinder 1, and the magnetic rod group 8 is fixed on the connecting plate 10, and the connecting plate 10 is connected to the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com