Metal deactivator discharge device

A metal passivator and material technology, applied in the direction of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of discontinuous production and increased production costs, and achieve strong continuous working ability, reduce waste, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

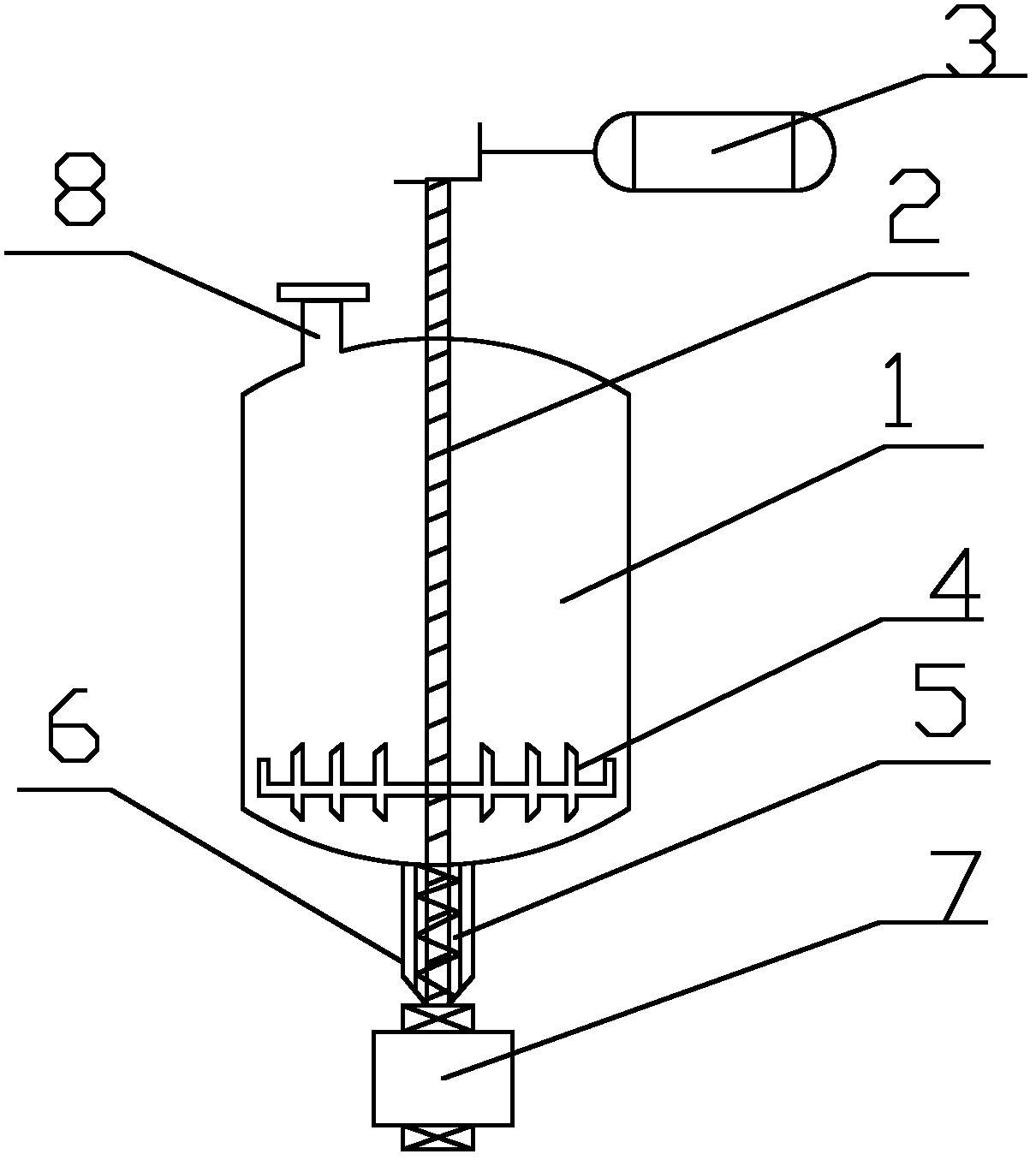

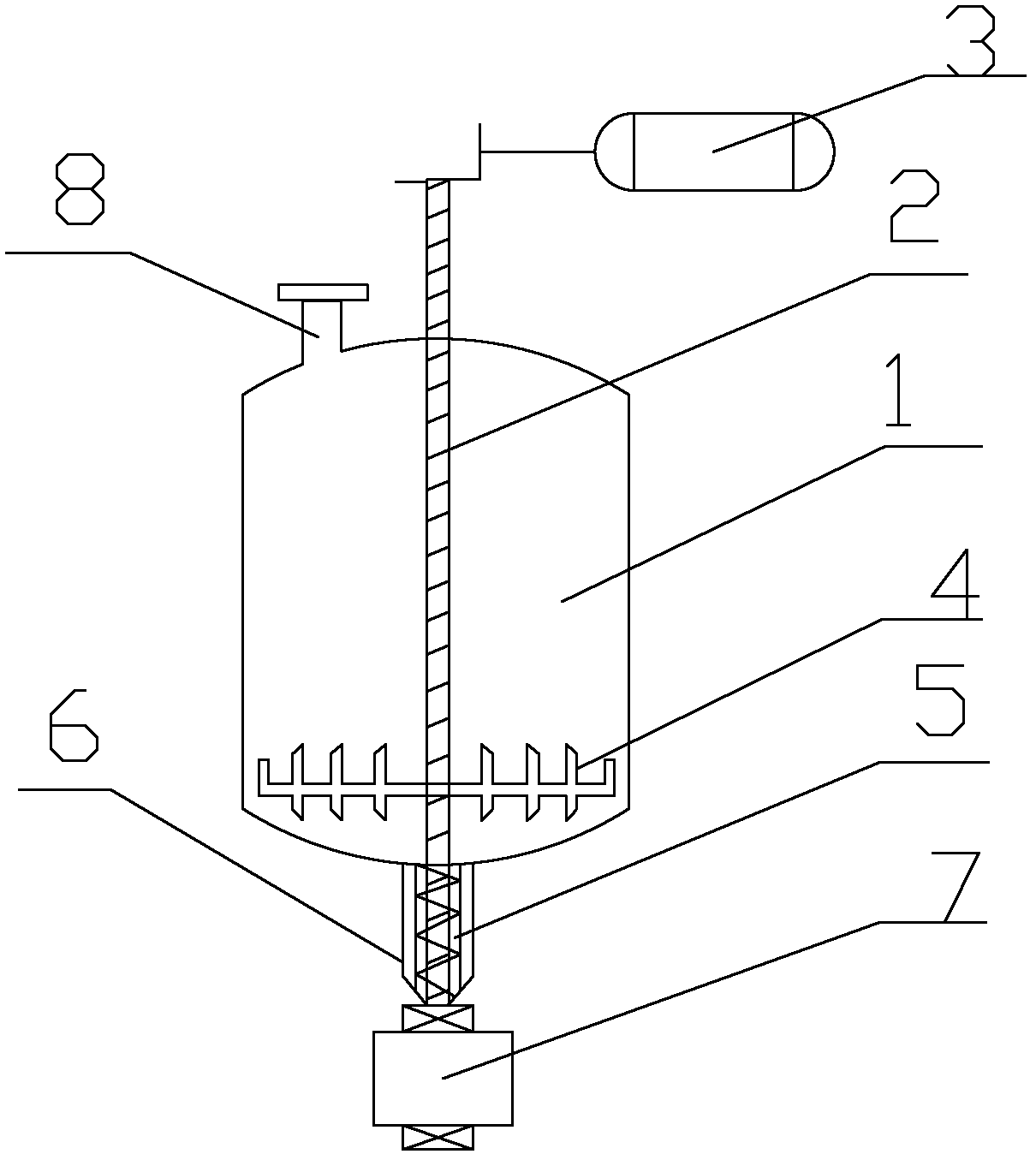

[0009] As shown in the figure, a metal passivating agent discharge device provided by the present invention includes a reactor 1, a rotating shaft 2 runs through the reactor 1, and the outer side of the rotating shaft 2 is connected with a motor 3, and the rotating shaft 2 is connected to the reactor 1. A scraper 4 is connected inside, and a discharge stirring cage 5 is arranged on the outside of the rotating shaft 2 below the reaction kettle 1, and a rubber ring is set on the outside of the joint between the reaction kettle 1 and the discharge stirring cage 5, and a stirring cage is set on the outside of the excretion stirring cage 5. A storage box 7 is provided directly below the cage casing 6 and the excretion stirring cage 5, and a material inlet 8 is opened on the top of the reaction kettle 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com