Juicer with air bleeding function

A technology of juice extractor and gas function, applied in the field of juice extractor with gas extraction function, can solve the problems of brown appearance, loss of vitamin nutrients, poor taste, etc., to reduce nutrient loss, reduce browning, use The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

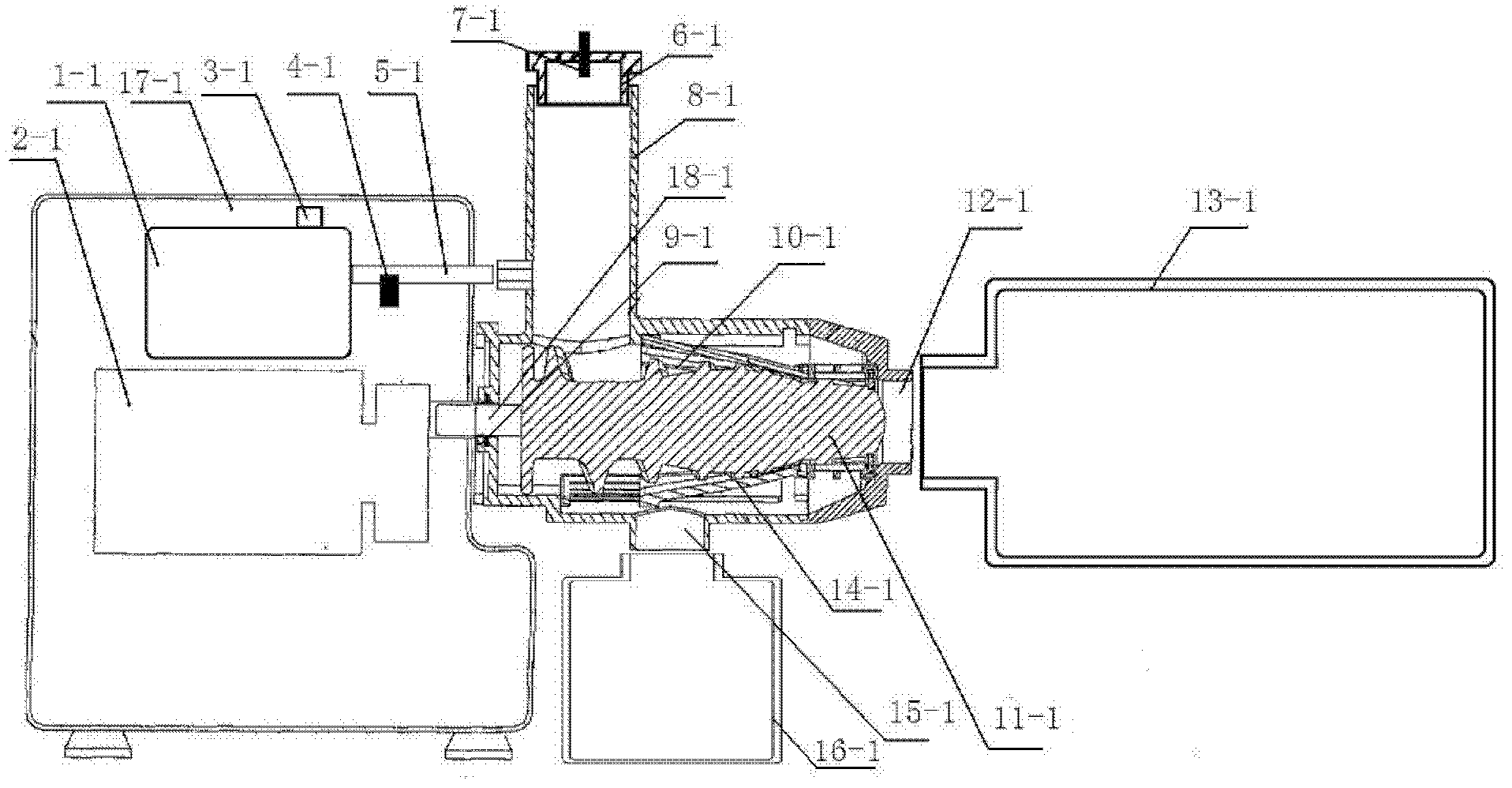

[0069] figure 1 Shown is a schematic diagram of the first embodiment of the juice extractor with air extraction function of the present invention, which is an improvement based on the screw extrusion juice extractor.

[0070] The juice extractor includes a base 17-1, a juice extraction motor 2-1, a juice extraction cavity 10-1, a juice receiving part, and a residue part. The juice receiving part in this embodiment is a juice receiving container 16-1, and the residue part is Residue container 13-1. A juice outlet 15-1 and a residue outlet 12-1 are provided on the juice extraction cavity 10-1. An integrated feed barrel 8-1 is installed on the juice extraction cavity 10-1, between the feed barrel 8-1, the juice extraction cavity 10-1, the juice receiving container 16-1, and the residue container 13-1 Form cavities that pass through each other. The juice extraction motor 2-1 is installed in the base 17-1, and the base 17-1 can be on the side of the juice extraction cavity 10-1 or a...

Embodiment 2

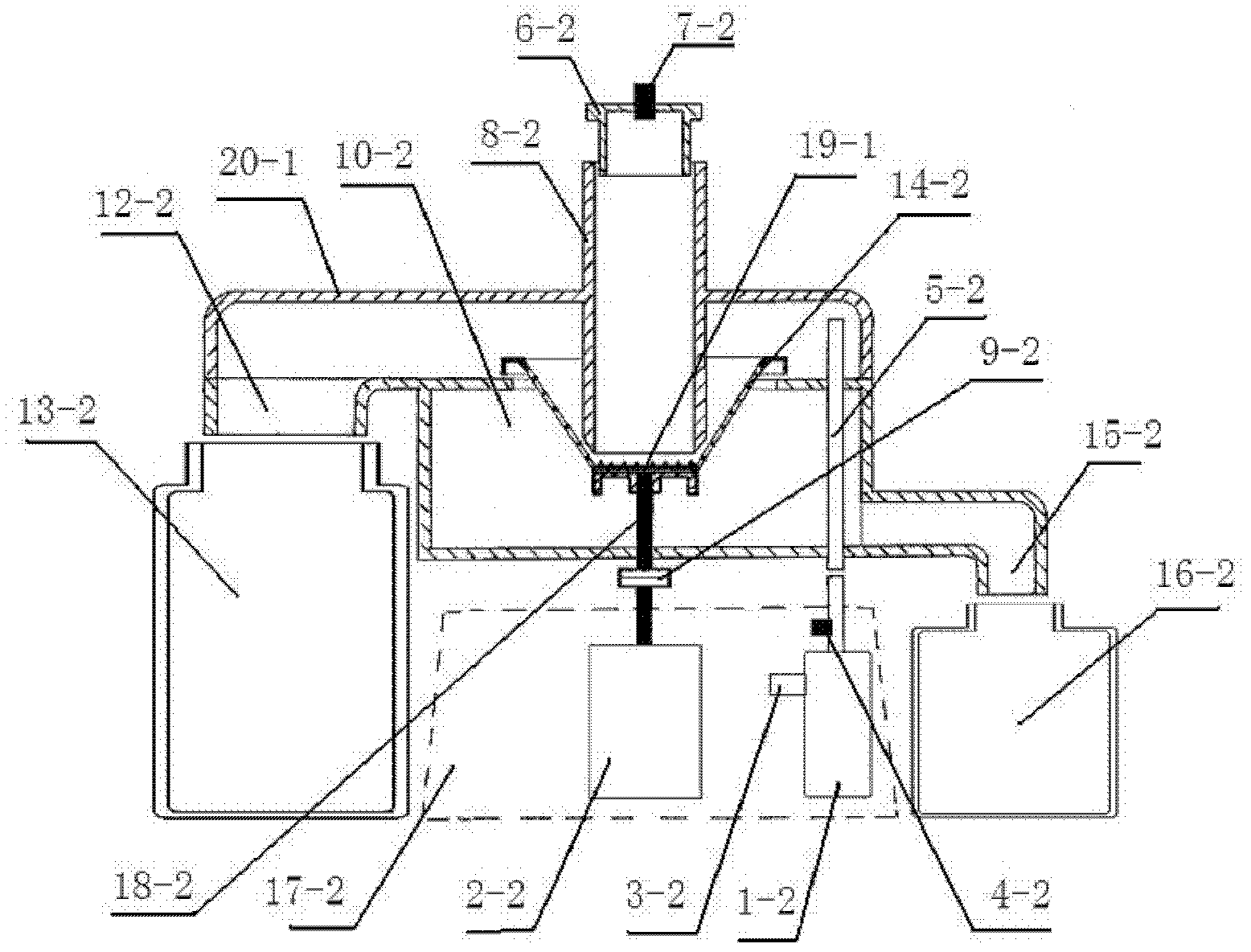

[0084] figure 2 Shown is a schematic diagram of the second embodiment of the juice extractor with air extraction function of the present invention, which is an improvement on the basis of the centrifugal basic juice extractor.

[0085] The juice extractor includes a base 17-2, a juice extraction motor 2-2, a juice extraction cavity 10-2, a juice receiving part, and a residue part. The juice receiving part in this embodiment is a juice receiving container 16-2, and the residue part It is the residue container 13-2. A juice outlet 15-2 and a residue outlet 12-2 are provided on the juice extraction cavity 10-2. The juice extraction motor 2-2 is installed in the base 17-2, and the base 17-2 can be on the side of the juice extraction cavity 10-2 or at the lower part of the juice extraction cavity 10-2. The base 17-2 in this embodiment is located at the lower part of the juice extraction cavity 10-2. A centrifugal juice extraction mechanism is installed in the juice extraction cavit...

Embodiment 3

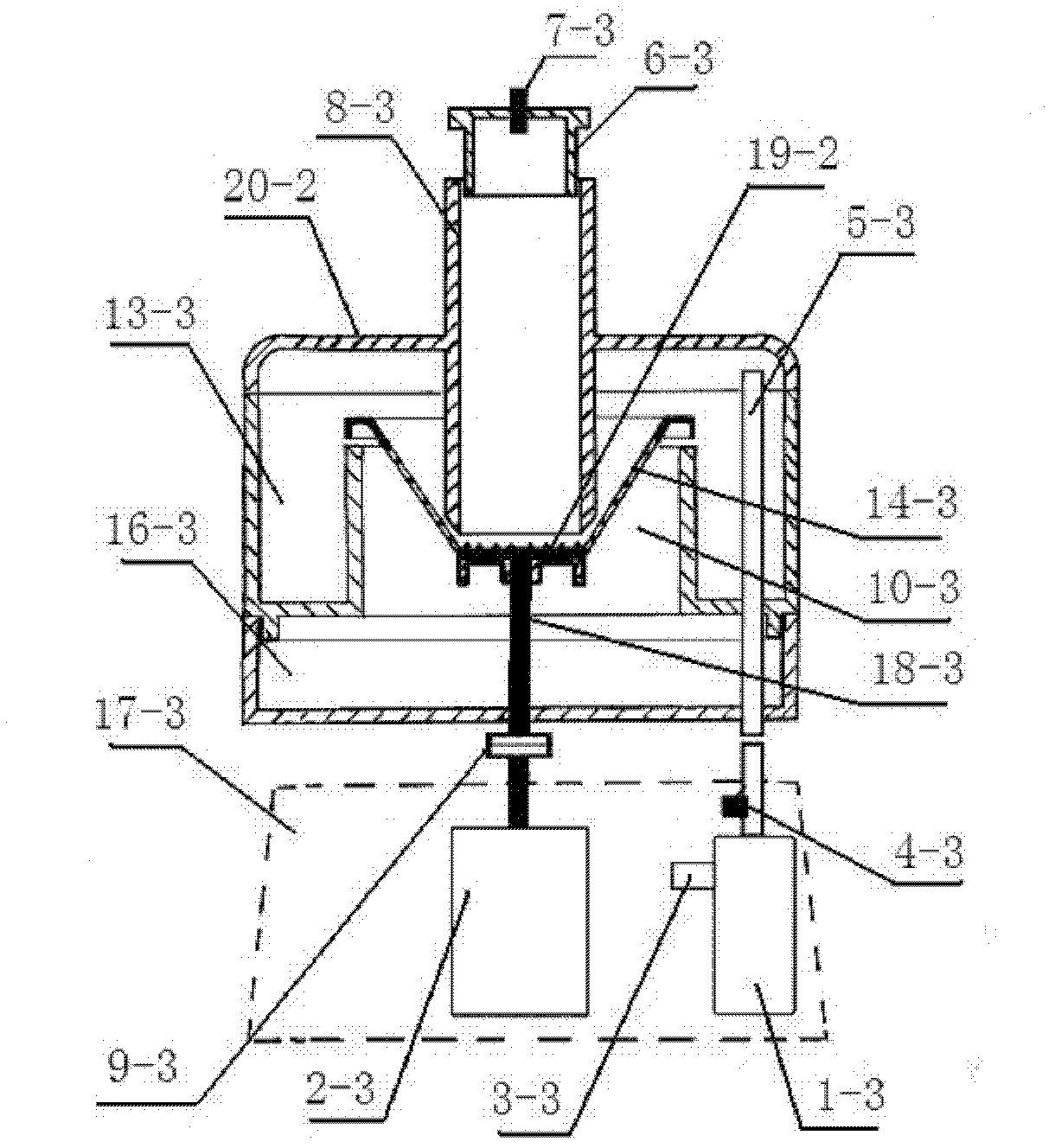

[0103] image 3 Shown is a schematic diagram of the third embodiment of the juice extractor with air extraction function of the present invention, which is an improvement based on the centrifugal juice extractor that combines the juice receiving container, the residue container and the juice extraction cavity.

[0104] The juice extractor includes a base 17-3, a juice extraction motor 2-3, a juice extraction cavity 10-3, a juice receiving part, and a residue part.

[0105] The juice extraction cavity 10-3 is composed of an upper cover part 20-2, a juice receiving container 16-3 and a residue container 13-3. The upper cover part 20-2 of the juice extraction cavity is provided with a feeding barrel 8-3.

[0106] The juice receiving part is a juice receiving container 16-3, and the residue part is a residue container 13-3. The juice extraction motor 2-3 is installed in the base 17-3, and the base 17-3 in this embodiment is located at the lower part of the juice extraction cavity 10-3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com