The unit structure of ear-picking straw crushing

A straw crushing and unitary technology, which is applied to cutters, agricultural machinery and implements, applications, etc., can solve the problems of large vibration of the unit, large power consumption, and high requirements for machine space structure, and achieves obvious sliding cutting effect and power consumption. Small, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

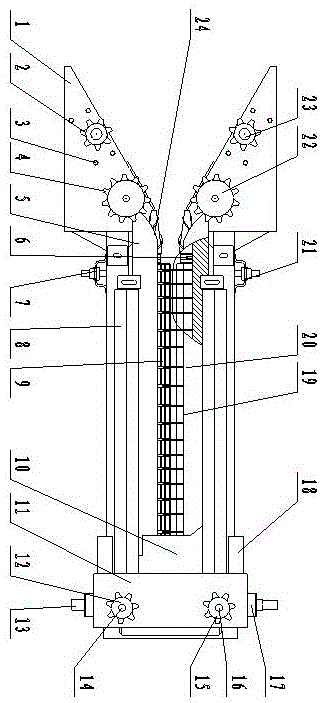

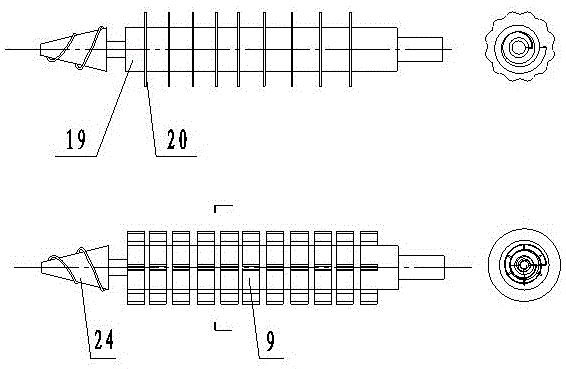

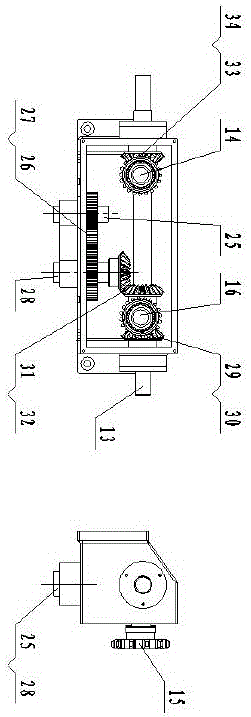

[0016] Such as Figure 1-3 In the shown embodiment: a unit body structure for harvesting corn ears and crushing the stalks to return to the field. The front end of the whole crushing and ear picking unit structure, the ear picking device and the straw crushing device are installed at the rear of the grain dividing device 1, wherein the ear picking device and the straw crushing device share a pair of crushing rollers 19,24, except for the crushing rollers 19,24, The ear picking device also includes the ear picking plate 5 installed above the crushing rollers 19,24, and the straw chopping device also includes a plurality of notch disc cutters 20 and grooved hexagonal knives installed on the two crushing rollers 19,24 respectively. Knife holder 9, wherein a plurality of gap disc cutters 20 are installed on the right crushing roller 19, and cutter holder 9 is installed on the left side crushing roller 24, has a plurality of grooves corresponding to the gap disc cutter on the cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com