Processing method of glass fibre board

A glass fiber board and processing method technology, applied in electrical components, printed circuit manufacturing, printed circuits, etc., can solve problems such as unusable, failed electrical tests, insufficient residual thickness stress, etc., to improve accuracy and improve product ease. Measure and improve the effect of hole deviation problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

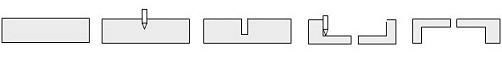

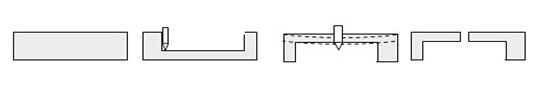

[0010] The specific embodiment of the present invention is described below in conjunction with accompanying drawing, figure 1 It is a schematic diagram of the implementation of the present invention, and the five stages are respectively 1, glass fiber board; 2, start drilling; 3, drilling; 4, countersinking; Compared figure 2 It is a schematic diagram of processing in the prior art, which is divided into four stages: 1. Glass fiber board; 2. Counterbore; 3. Drilling (the board body is bent due to insufficient stress); 4. Finished processing.

[0011] When processing glass fiber boards, choose glass fiber boards with a surface layer of 2116 cloth. If necessary, grind them first to ensure their flatness.

[0012] Firstly, drill positioning holes on the fiberglass board according to the center positioning of both sides of the board.

[0013] Place the board on the processing machine, put the wood pulp board under the board, and lay the aluminum sheet on the top. After confirmi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com