Pavement interlayer bonding strength detector

A technology of bonding strength and pavement interlayer, which is applied in the field of detectors, can solve problems such as error, data collector interference detection results, and reduce the actual detection ability of the instrument, and achieve the effect of simple structure, novel and reasonable design, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

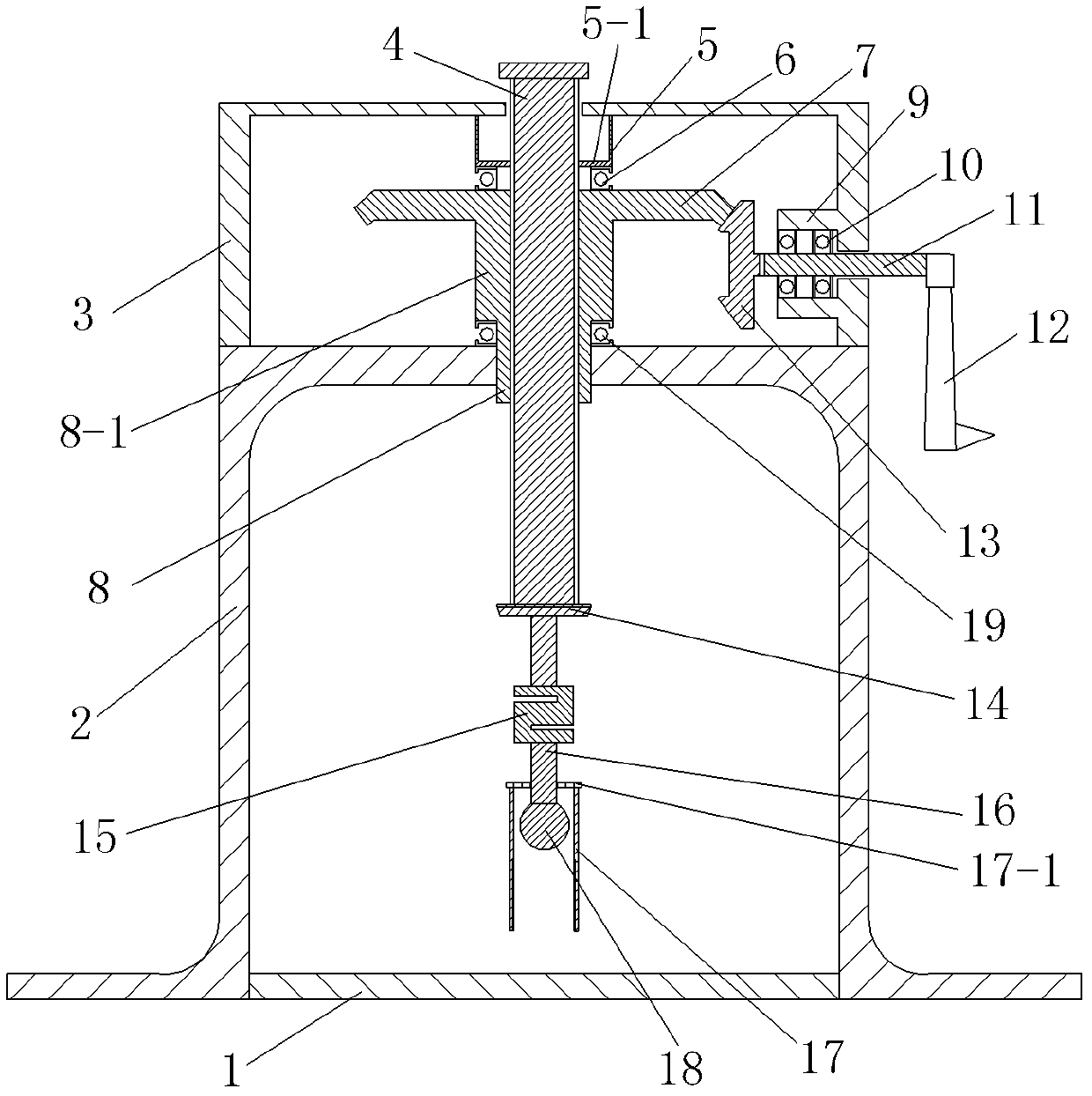

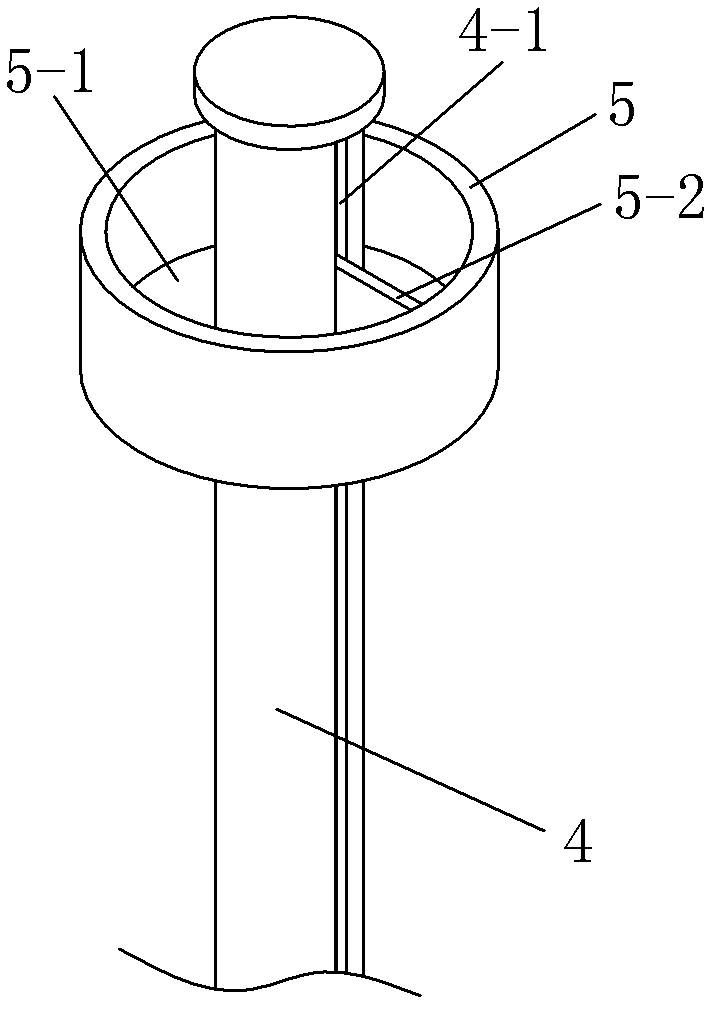

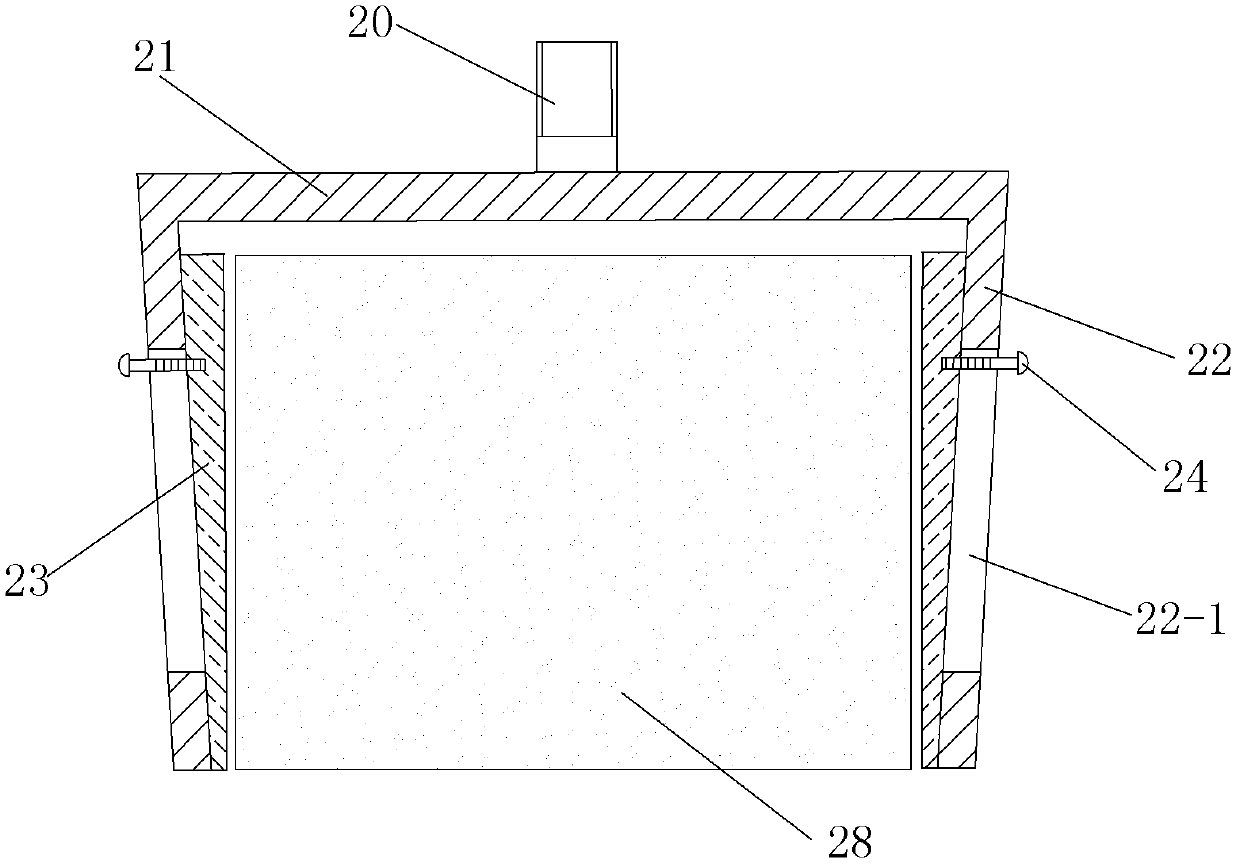

[0041] Such as figure 1 , figure 2 and image 3The shown a kind of pavement interlayer bond strength tester comprises a base 1, a frame 2 installed on the base 1 and a frame 2 3 installed on the frame 2, the upper part of the frame 2 is movably equipped with nuts 8. The upper part of the nut 8 is horizontally provided with a bevel gear 1 7, and a shaft for supporting the rotation of the nut 8 and limiting the axial displacement of the nut 8 and the bevel gear 1 7 is provided between the frame 1 2 and the frame 2 3 To the limiting device, the side of the nut 8 on the frame two 3 is rotatably connected with a rotating shaft 11, and one end of the rotating shaft 11 stretches out from the frame two 3, and the end of the rotating shaft 11 located in the frame two 3 is vertically provided with The second bevel gear 13 matched with the bevel gear one 7, the end of the rotating shaft 11 outside the frame two 3 is provided with a handle 12 for driving the rotating shaft 11 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com