Rock mass anisotropy osmotic coefficient in-situ test method and device thereof

A technology of anisotropy and permeability coefficient, applied in the field of in-situ testing of anisotropic permeability coefficient of rock mass, can solve the problems of high cost, large limitations, complex test methods, etc., and achieve simple structure, reasonable design and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the drawings and specific embodiments.

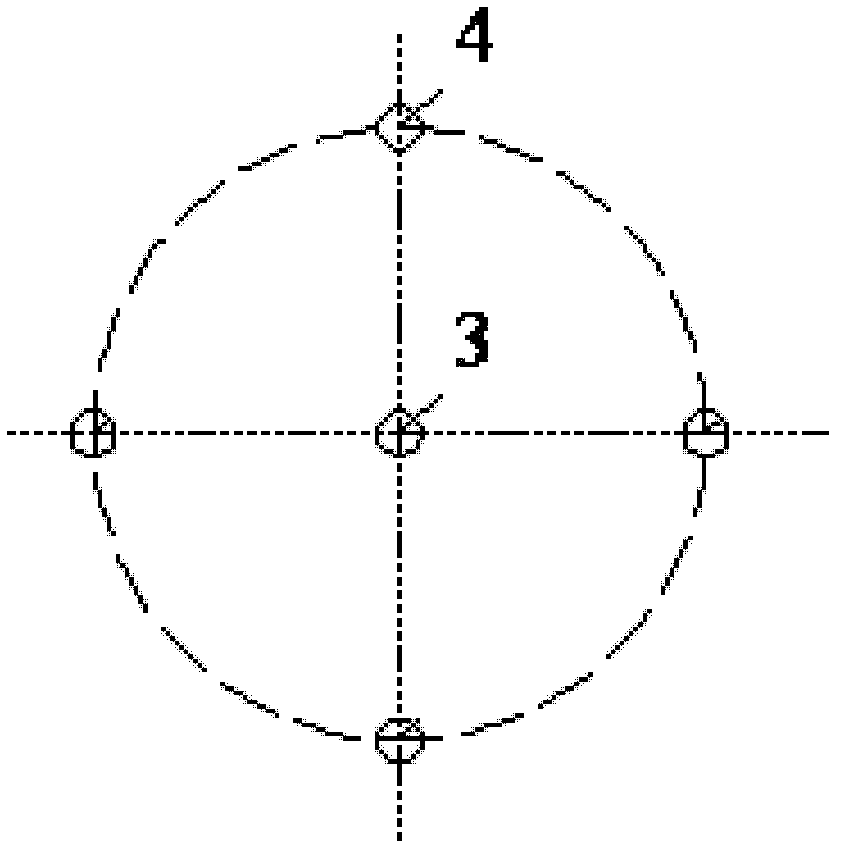

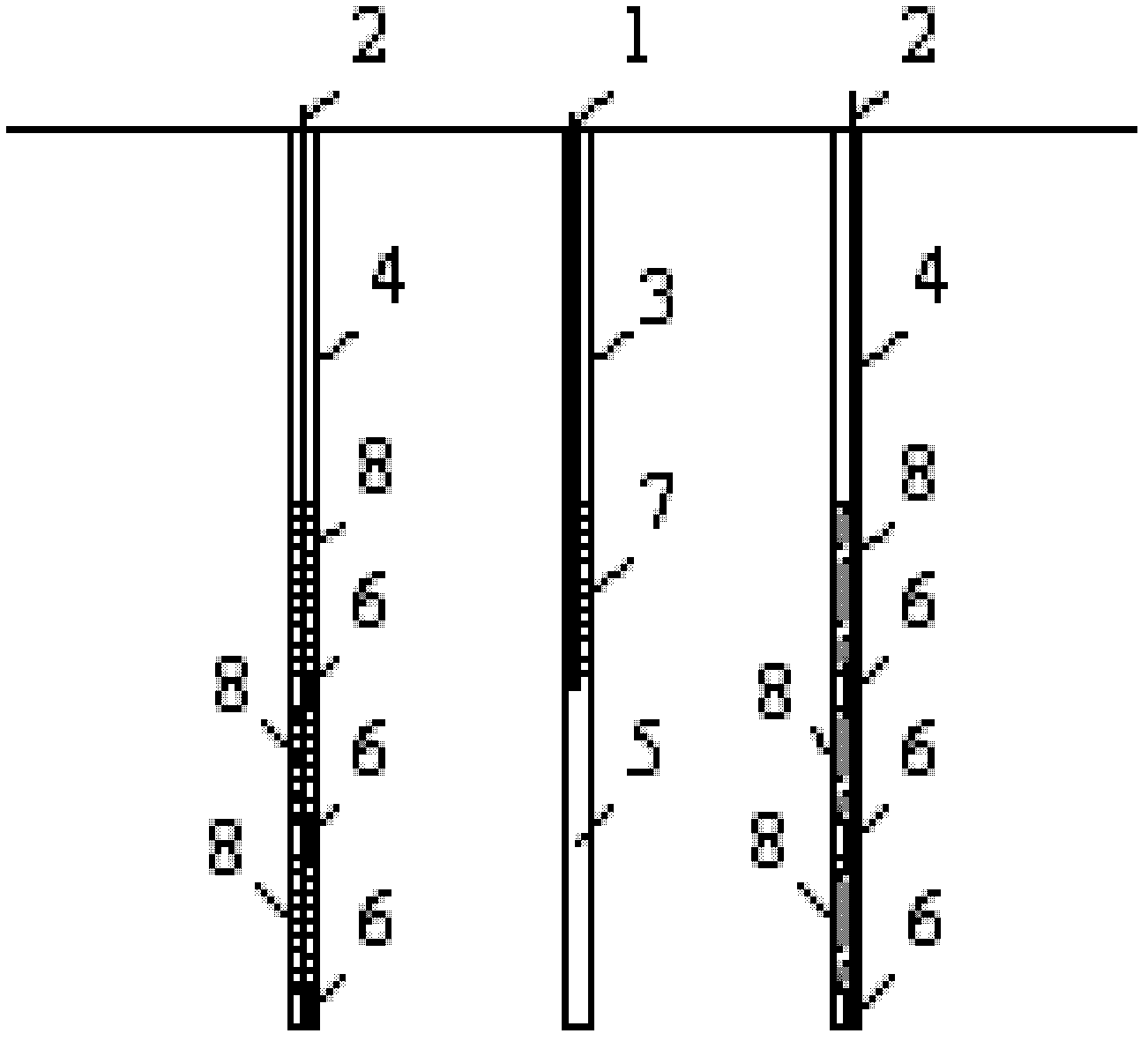

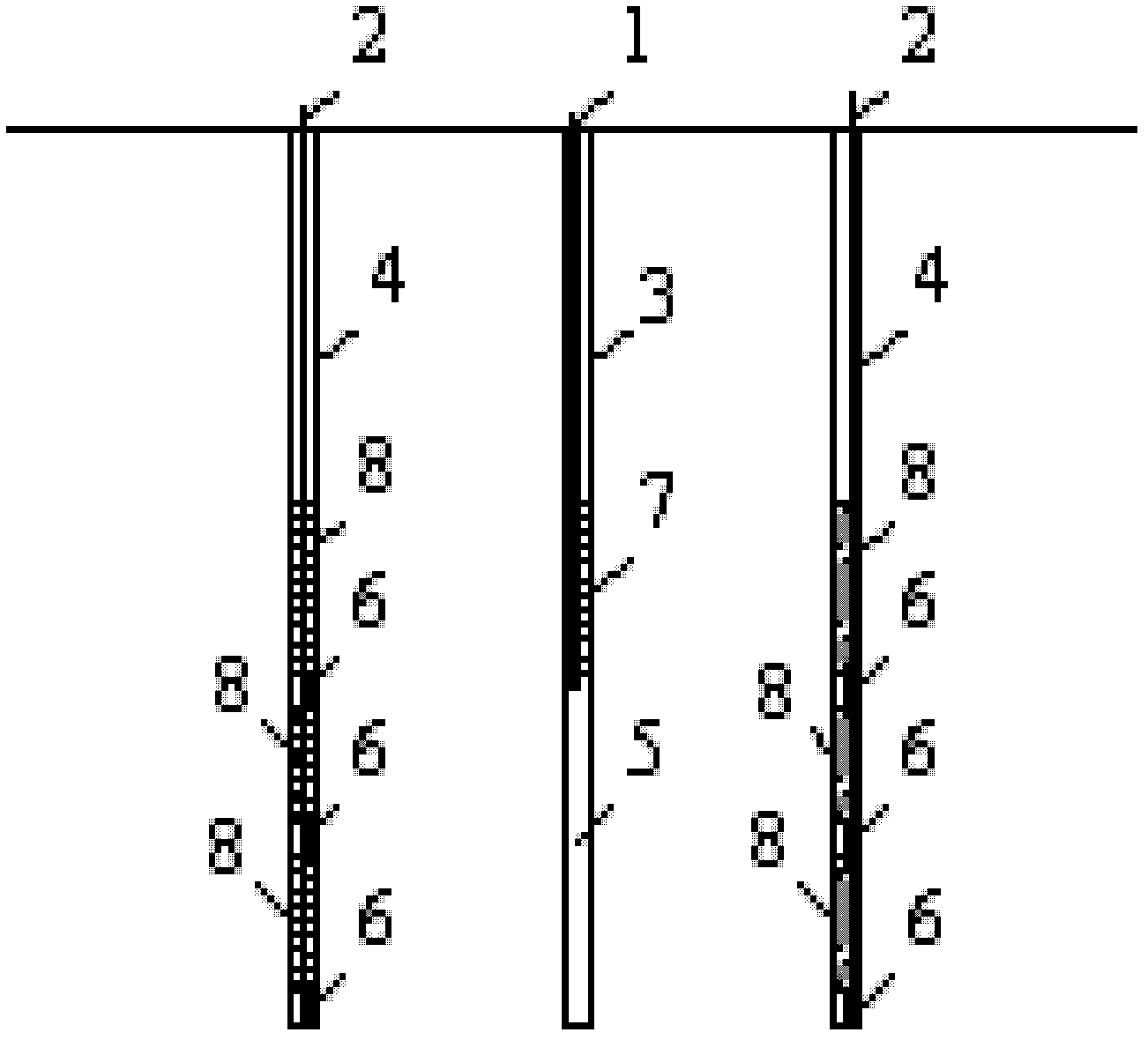

[0014] See figure 1 with figure 2 , With the pressurized water hole 3 as the center, 4 pressurized holes 4 are evenly arranged in the circumferential direction on a circle with a radius of 3 to 5 meters. The length of the pressurized water hole 3 is equal to the length of each pressurized hole 4, 3 is provided with a high pressure water stop plug 7 to form a water pressure section 5, the water inlet pipe 1 passes through the high pressure water stop plug 7 and communicates with the water pressure section 5, the length of the water pressure section 5 of the water pressure hole 3 is 5-10 meters, The bottom elevation of each seepage hole 4 is the same as the bottom height of the pressurized water hole 3. Each pressurized hole 4 is parallel to the pressurized water hole 3, and each pressurized hole 4 is equipped with three osmometers 6 The positions of the 3 piezo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com