Air sac pushing device for motor vehicle collision test

A vehicle collision and propulsion device technology, applied in the field of rail vehicles, can solve the problems of short gas impact time, high manufacturing difficulty, long construction period, etc., and achieve the effects of low cost, simple production, high energy and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

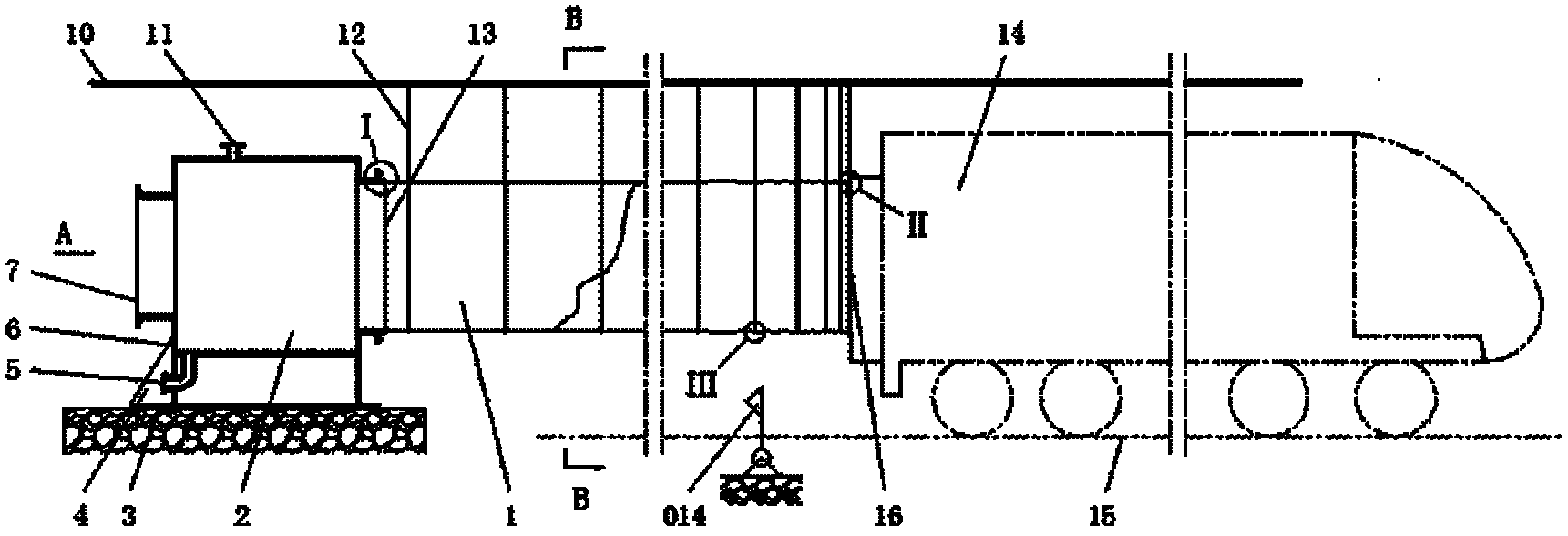

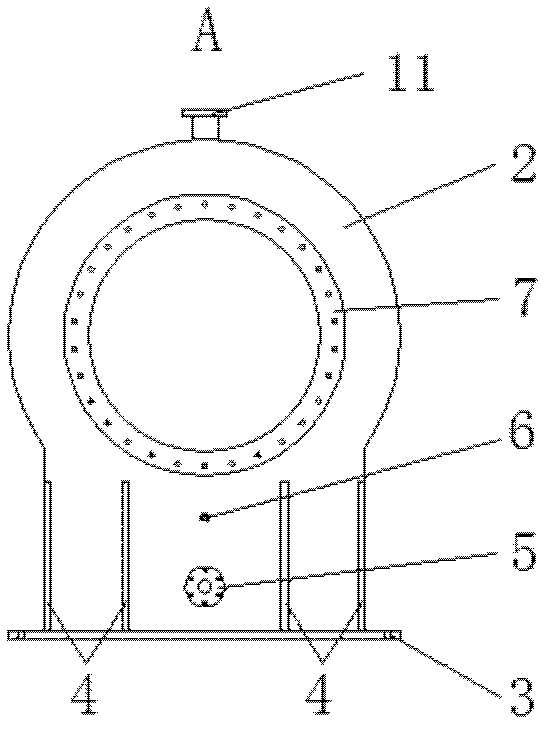

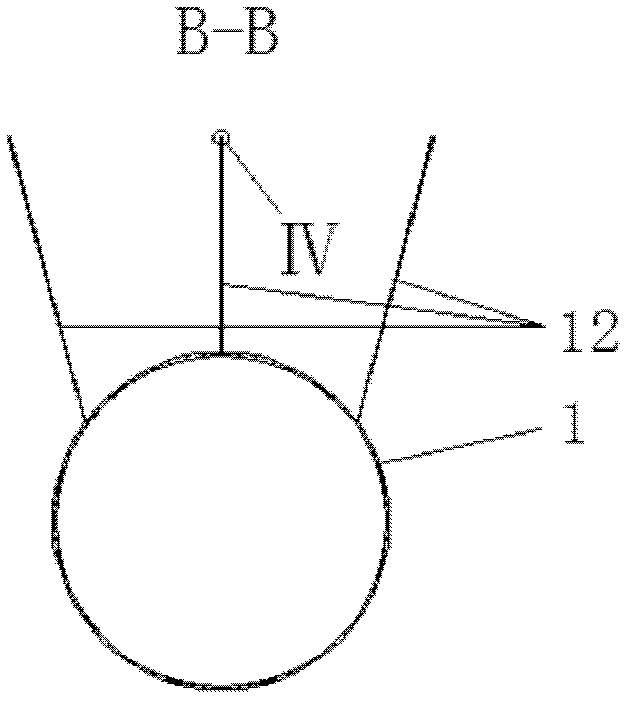

[0017] An embodiment of the present invention provides an airbag propulsion device for a locomotive vehicle collision test, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the device includes: a fixed inflatable cylinder body 2 and a collapsible cylindrical flexible air bag 1. The inflatable cylinder body 2 is provided with a mounting seat 3 , an air inlet 7 , an exhaust port 11 , a water discharge port 5 , an air gauge interface 6 and an air bag interface 13 . The mounting seat 3 set on the fixed inflatable cylinder body 2 is connected with the foundation, the air inlet 7 is connected with the air supply system, the exhaust port 11 is connected with the exhaust valve, the drain port 5 is connected with the drain valve; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com