Underground cavity volume detection method and underground cavity volume detection device

A cavity and volume technology, applied in the field of geology and detection, can solve problems such as increased detection difficulty, decreased detection accuracy, and roof damage in the burn-out area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1: distribution coefficient K d Determination of

[0070] By simulating the formation of underground cavities in the laboratory, the combustion, heating or gasification residues were taken to measure the adsorption characteristics. The specific operation is as follows: put the lignite gasification residues of Dayan Coalfield with a mass of M mg into the container, and prepare the concentration for a 1 mg / L, a 2 mg / L, a 3 mg / L, a 4 mg / L, a 5 mg / L tracer (fluorescein sodium) solution, the gasification residue is mixed with 1000ml of the solution, where M and a n The relationship satisfies: 0.0032≤a 5 / M4 / M3 / M2 / M1 / M≤0.0047, shake on the shaker for 48 hours, then filter the sample, and test the concentration of tracer (fluorescein sodium) in the filtrate to be b 1 mg / L,b 2 mg / L,b 3 mg / L,b 4 mg / L,b 5 mg / L.

[0071] by different a 1 mg / L, a 2 mg / L, a 3 mg / L, a 4 mg / L, a 5 mg / L different concentration test, according to K d =(a-b) / a Calcu...

Embodiment 2

[0075] Example 2: Application of Volume Detection in Underground Coal Gasification Burn-out Area

[0076] 1. Obtain the adsorption characteristics of the gasification residue on the tracer (sodium fluorescein):

[0077] Before gasification in the underground coal gasification furnace, the lignite in the area to be gasified was used for a simulated underground gasification combustion test, and the burned coal ash was tested with reference to Example 1 to obtain the adsorption characteristics of a specific tracer (sodium fluorescein) in it. (partition coefficient K d = 0.624).

[0078] 2. Strengthening measures for water disturbance in the burn-out area:

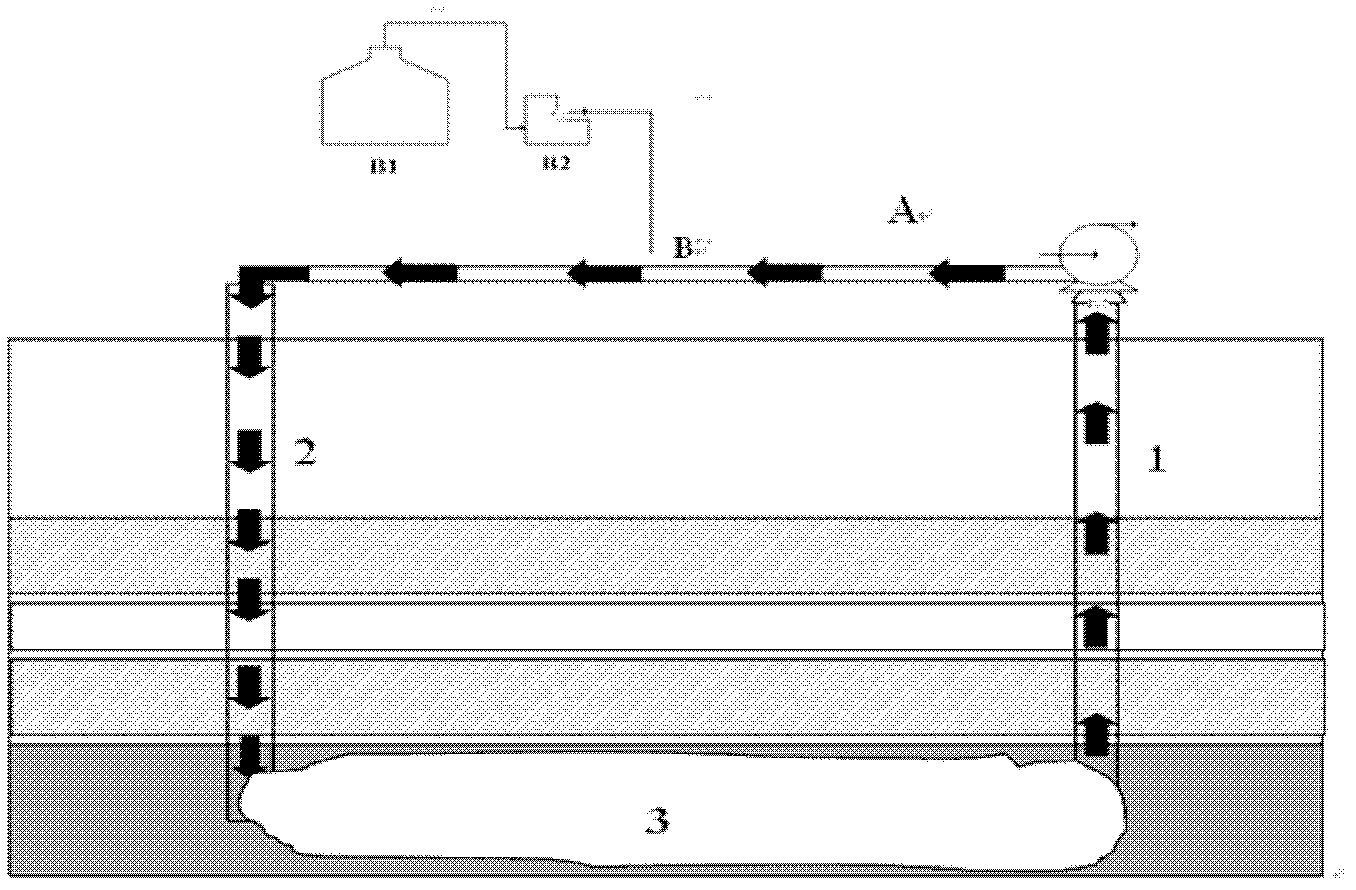

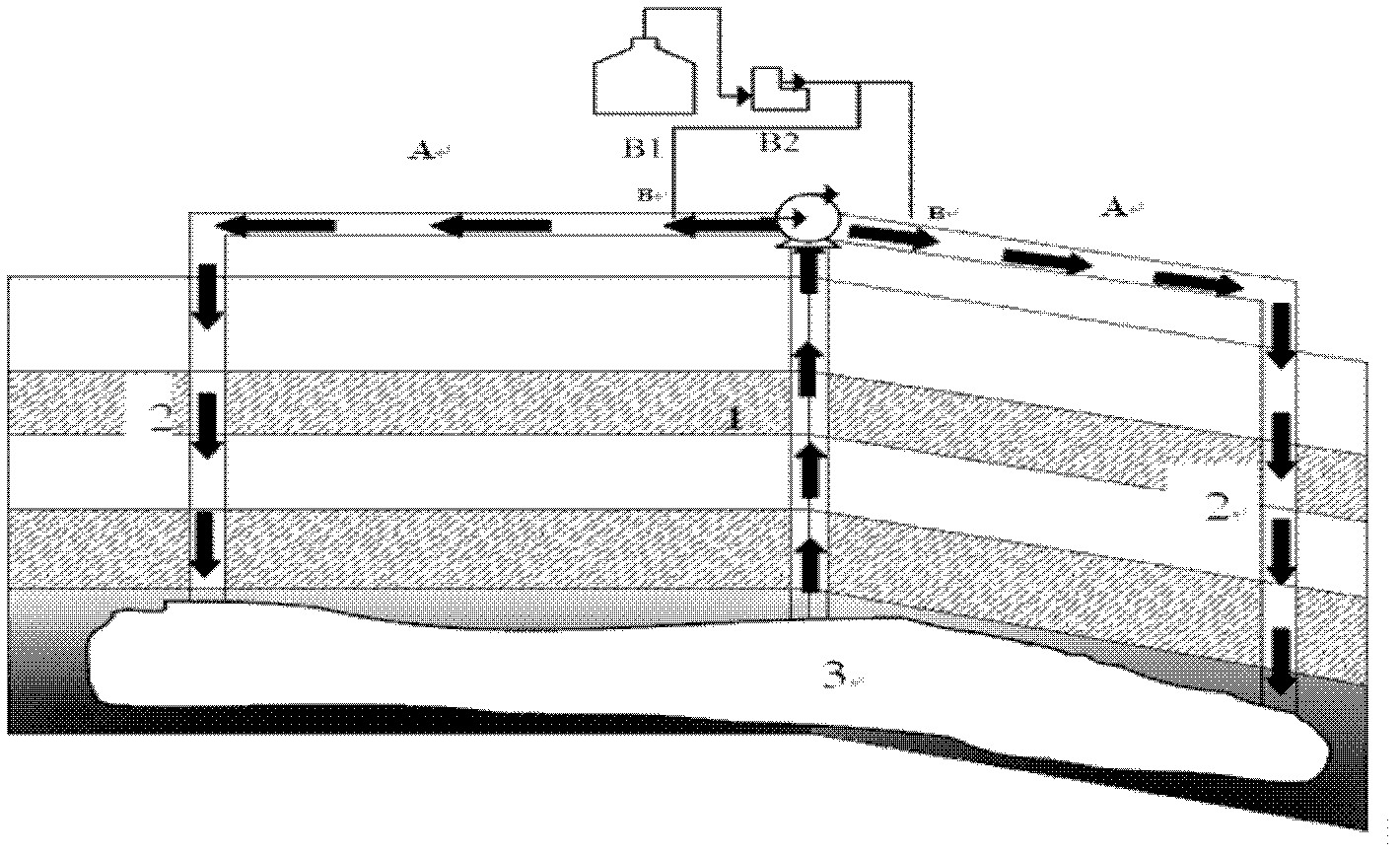

[0079] a. If figure 1 , after the gasified burn-out zone is filled with water, it needs to be disturbed by the ground water pump system, mainly using two connected boreholes 1 and 2 (with a diameter range of 150-400mm) to strengthen the circulation in the burn-out zone The water body is disturbed, and the water flow dire...

Embodiment 3

[0094] Example 3: Application of volume detection of oil shale burn-off zone

[0095] 1. Obtain the adsorption characteristics of the oil shale gob residue on the tracer (fluorescein sodium):

[0096] Before the oil shale is exploited, the oil shale samples in the area to be mined are obtained for testing under the same process conditions, and the oil shale gasification residue after the experiment is obtained by laboratory testing with reference to Example 1. Specific tracer (fluorescein sodium) Among them, the adsorption characteristics (partition coefficient).

[0097] 2. Strengthening measures for water disturbance in the burn-out area:

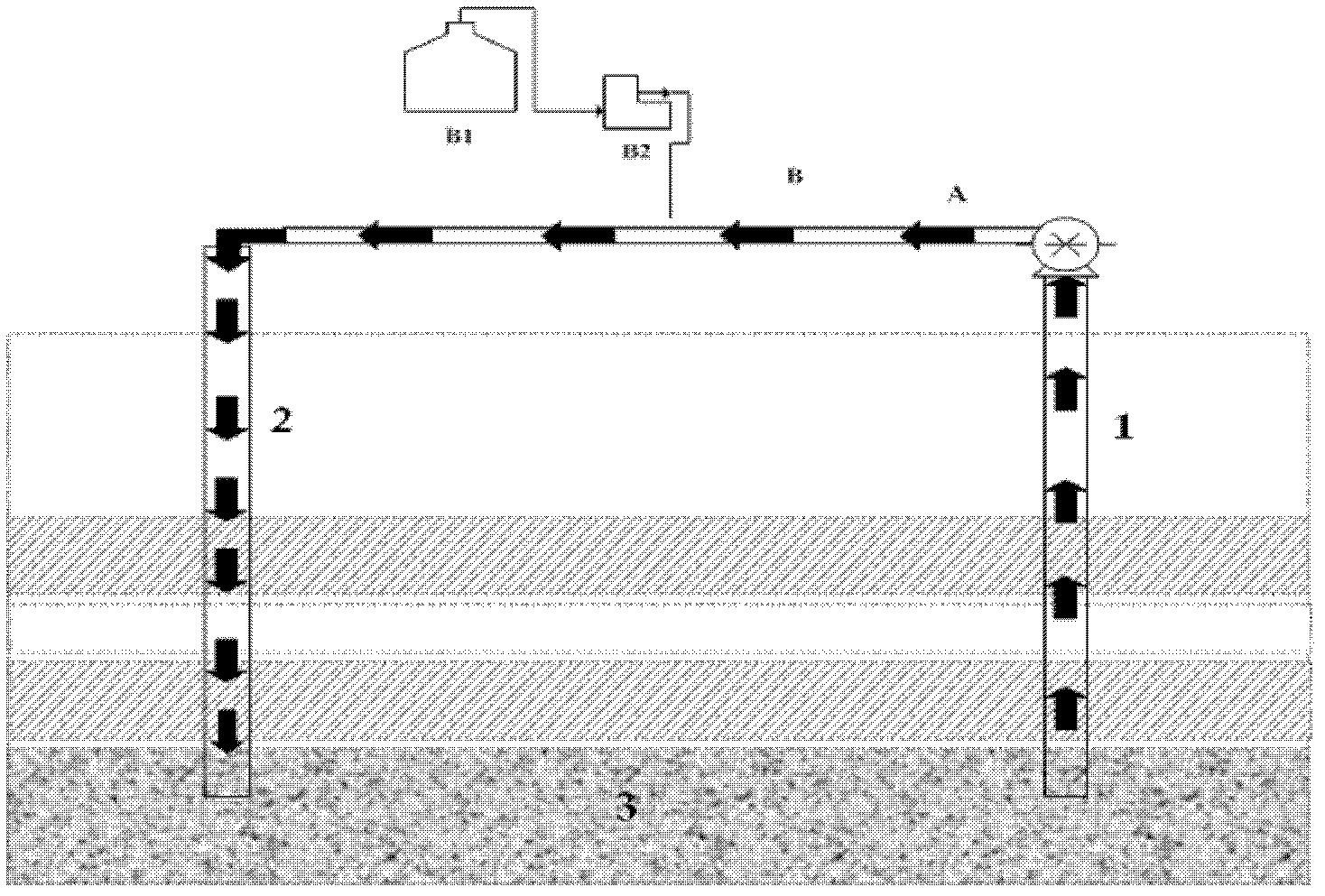

[0098] like image 3 After mining, the burn-out area is filled with water and needs to be disturbed by the surface water pump system. Two connected boreholes 1 and 2 (with a diameter range of 150-400mm) are used to circulate and strengthen the water disturbance in the burn-out area. , the water flow direction flows in the direction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com