Wheel profile laser measurement device

A measuring device and surface laser technology, applied in measuring devices, optical devices, instruments, etc., to achieve a high degree of automation, automatic storage and display, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

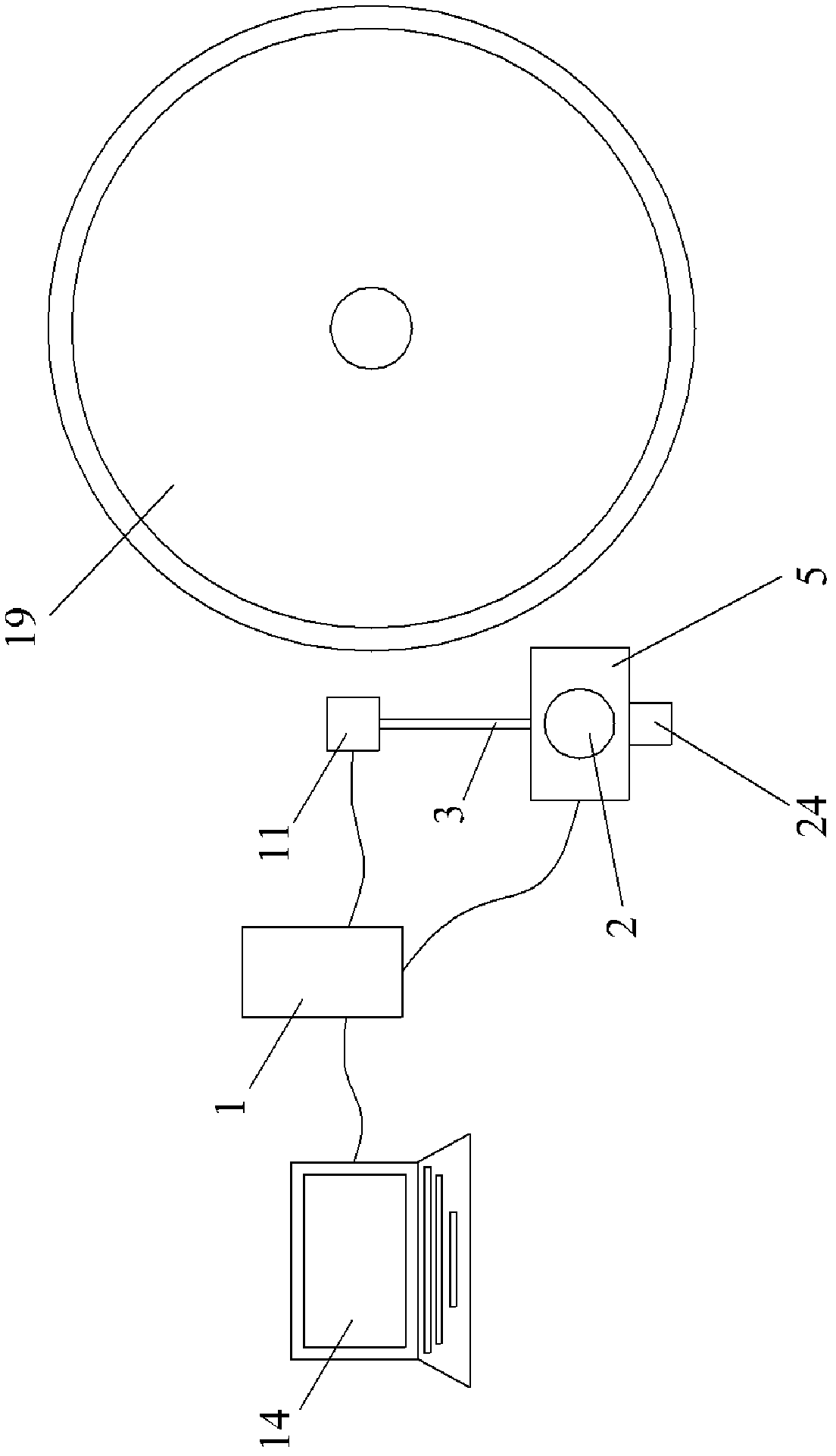

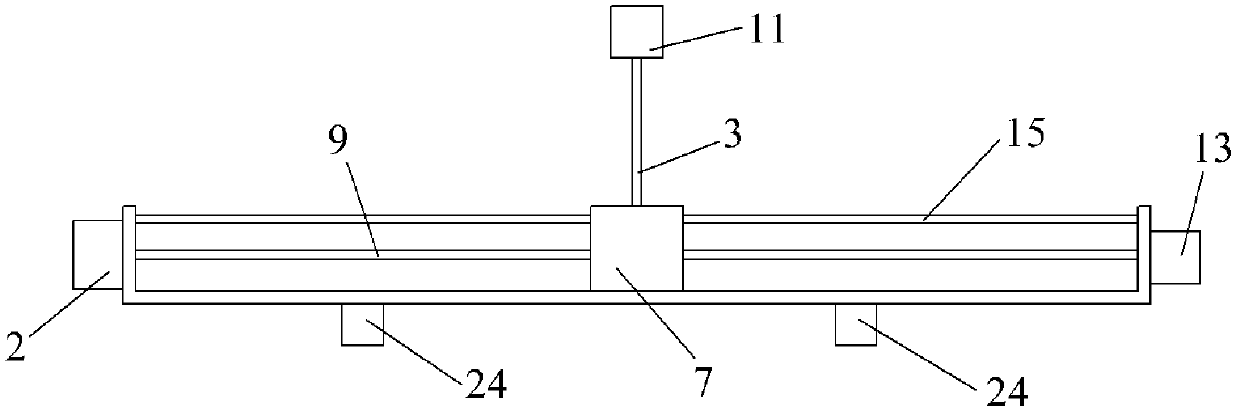

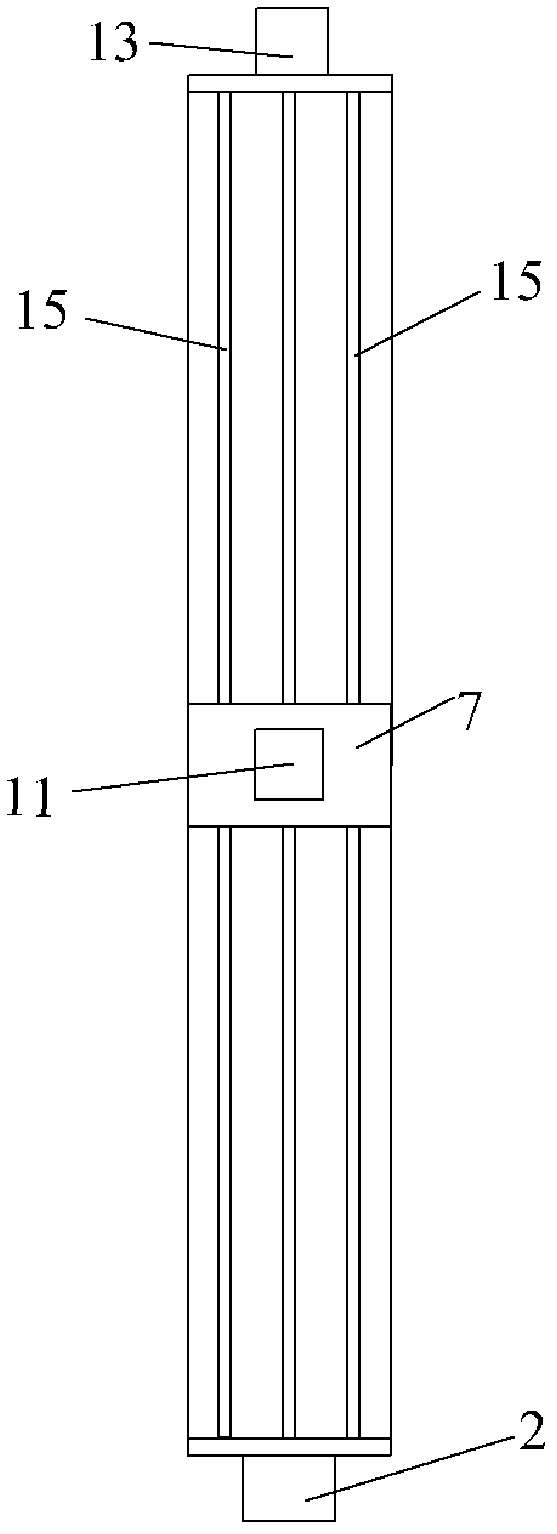

[0029] Figure 1-3 Shown, a specific embodiment of the present invention is, a kind of wheel profile laser measurement device, its composition is:

[0030] One end of the base 5 is fixed with a motor 2, the motor 2 is connected with the transmission screw 9, and the other end of the transmission screw 9 is installed with an incremental photoelectric encoder 13; the base 5 is also provided with a guide rod parallel to the transmission screw 9 15. The bottom of the base 5 is fixed on the rail through the support block 24; the moving slider 7 fits on the guide rod 15, and the moving slider 7 is also screwed with the transmission screw 9;

[0031] The moving bar 3 is fixed on the moving slider 7, the laser head 11 of the laser displacement sensor 1 is fixed on the top of the moving bar 3, the serial port and the USB interface of the laser displacement sensor 1 are respectively connected with the serial port and the USB interface of the computer 14, and the incremental photoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com